- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

High-Quality Shale Shaker Screen Mesh for Enhanced Oil & Gas Drilling Performance

Understanding Shale Shaker Screen Mesh Importance and Applications

Shale shaker screen mesh is a vital component in the drilling industry, specifically in the process of separating drill cuttings from the drilling fluid. The efficiency and effectiveness of shale shakers heavily rely on the quality and specifications of the screen mesh used. In this article, we will explore the significance of shale shaker screen mesh, its types, and its applications.

What is Shale Shaker Screen Mesh?

Shale shaker screen mesh refers to the perforated or woven screens that are installed on shale shakers—devices used to remove particulates from drilling fluids during the drilling process. These screens come in various materials, most commonly made of steel or composite substances, and have different mesh sizes tailored to specific drilling requirements.

Types of Shale Shaker Screen Mesh

There are primarily three types of screens used in shale shakers

1. Hook Strip Screens Commonly used in various drilling applications, hook strip screens are designed with hooks that allow for easy installation and replacement. They provide reliable support and effective filtration of drilling fluids.

2. Pretensioned Screens These screens are pre-stretched and bonded to a frame, enhancing their durability and life span. They are optimized for finer filtration and are frequently used in conditions where fluid cleanliness is critical.

3. Composite Screens Made from a combination of different materials, composite screens are known for their lightweight properties without sacrificing strength. They provide excellent corrosion resistance and reduce the overall weight of the shale shaker.

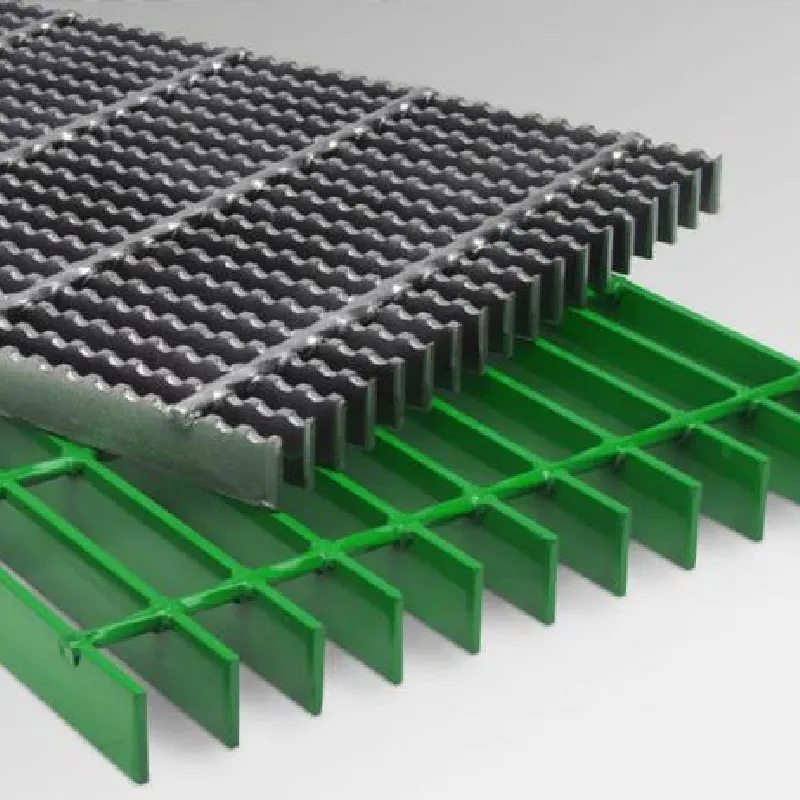

shale shaker screen mesh

Importance of Screen Mesh in Drilling Operations

The choice of shale shaker screen mesh significantly impacts the overall drilling performance. A mesh with the appropriate opening size ensures efficient separation of drill cuttings from the mud. If the mesh is too coarse, large cuttings may escape, leading to potential clogging in other equipment downstream. Conversely, if the mesh is too fine, it may result in excessive pressure drop and hinder the mud circulation.

Moreover, the durability of the screen mesh affects maintenance costs and downtime. High-quality screens can withstand the harsh conditions of drilling operations, minimize replacement frequency, and enhance productivity.

Applications in the Oil and Gas Industry

Shale shaker screen mesh is widely used in the oil and gas sector but also finds application in other industries such as

- Mining For separating coal, ore, or gravel from water during extraction processes. - Construction Filtering aggregate and slurry materials during project management. - Water Treatment In systems designed to remove solids from wastewater.

Conclusion

In summary, shale shaker screen mesh plays a crucial role in optimizing drilling operations by ensuring the efficient separation of solids from drilling fluids. Understanding the types and functionalities of these screens allows operators to make informed choices, leading to enhanced drilling performance and operational efficiency. As the oil and gas industry continues to evolve, so too will the technologies behind shale shaker screens, driving advancements in efficiency and sustainability in drilling practices.

-

Upgrade Your Industrial Operations with Durable Steel GratingNewsJul.21,2025

-

Transform Your Flooring Solutions with Quality Floor GratingNewsJul.21,2025

-

Top-Quality Shale Shaker Screens for Your Drilling NeedsNewsJul.21,2025

-

High-Quality Steel Grating for All Your Industrial NeedsNewsJul.21,2025

-

Explore the Durability and Versatility of Galvanized Steel GratingNewsJul.21,2025

-

Ensure Maximum Safety with Premium Safety NetsNewsJul.21,2025