- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

helmi . 15, 2025 13:50

Back to list

steel walkway grating

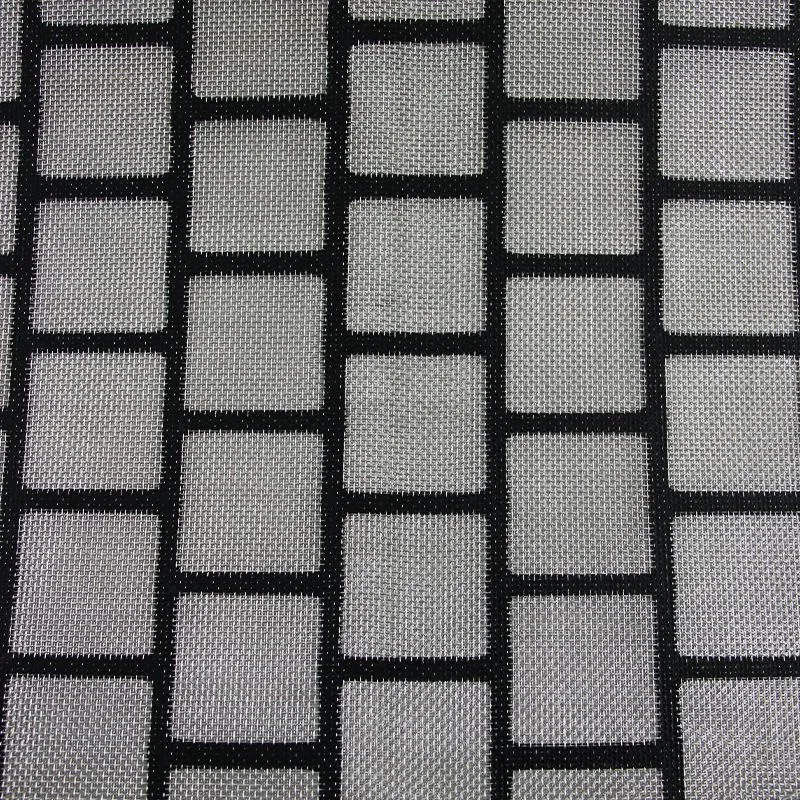

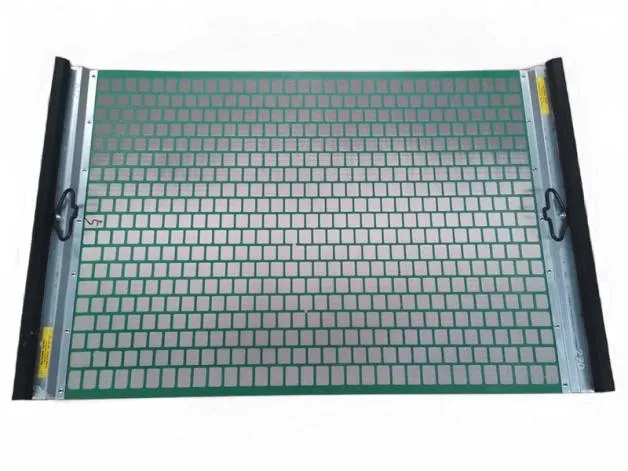

Galvanized grating steps stand as a quintessential solution in various industrial and commercial applications, offering a balance between durability, safety, and cost-effectiveness. These steps are constructed primarily from steel and undergo a galvanization process to enhance their resistance to elements like corrosion and wear. Their versatile nature allows them to be utilized in environments ranging from chemical plants to high-traffic commercial areas.

From an engineering perspective, producing galvanized grating steps involves precise techniques and quality materials. The quality control in manufacturing ensures that each piece meets rigorous standards, a testament to their reliability and performance. Companies seeking to invest in these steps should consider suppliers who adhere to international standards like ASTM A123, the standard specification for zinc coatings on iron and steel products, to ensure they receive products of the highest quality. When comparing the cost-effectiveness of galvanized grating steps to other materials, they offer substantial savings in the long term. While initial investments might be higher than alternatives, their durability and low maintenance needs mean reduced costs over time. They do not require frequent replacements or extensive upkeep, resulting in savings that reflect positively in both financial statements and project timelines. When choosing the right type of galvanized grating steps for specific applications, consider load-bearing requirements, environmental conditions, and aesthetic preferences. Different types of grating, such as serrated or smooth, might be more suitable for certain settings. Consulting with experts who understand these aspects ensures optimal product choice and maximizes performance and safety. The credibility of suppliers and manufacturers is another critical consideration. Partnering with reputable suppliers guarantees a consistent quality of grating steps, adherence to delivery schedules, and compliance with safety standards. Make sure to verify the credentials of manufacturers through certifications and customer reviews to establish a trust-based relationship. In conclusion, galvanized grating steps represent a fusion of engineering excellence and functional design, catering to a vast range of industrial and commercial needs. Their resilience against harsh environmental conditions, combined with cost efficiencies and safety features, make them an indispensable component in modern infrastructure. By investing in high-quality galvanized grating steps, businesses can enhance safety, reduce long-term expenses, and add value to their facilities while maintaining an aesthetic that aligns with modern architectural trends.

From an engineering perspective, producing galvanized grating steps involves precise techniques and quality materials. The quality control in manufacturing ensures that each piece meets rigorous standards, a testament to their reliability and performance. Companies seeking to invest in these steps should consider suppliers who adhere to international standards like ASTM A123, the standard specification for zinc coatings on iron and steel products, to ensure they receive products of the highest quality. When comparing the cost-effectiveness of galvanized grating steps to other materials, they offer substantial savings in the long term. While initial investments might be higher than alternatives, their durability and low maintenance needs mean reduced costs over time. They do not require frequent replacements or extensive upkeep, resulting in savings that reflect positively in both financial statements and project timelines. When choosing the right type of galvanized grating steps for specific applications, consider load-bearing requirements, environmental conditions, and aesthetic preferences. Different types of grating, such as serrated or smooth, might be more suitable for certain settings. Consulting with experts who understand these aspects ensures optimal product choice and maximizes performance and safety. The credibility of suppliers and manufacturers is another critical consideration. Partnering with reputable suppliers guarantees a consistent quality of grating steps, adherence to delivery schedules, and compliance with safety standards. Make sure to verify the credentials of manufacturers through certifications and customer reviews to establish a trust-based relationship. In conclusion, galvanized grating steps represent a fusion of engineering excellence and functional design, catering to a vast range of industrial and commercial needs. Their resilience against harsh environmental conditions, combined with cost efficiencies and safety features, make them an indispensable component in modern infrastructure. By investing in high-quality galvanized grating steps, businesses can enhance safety, reduce long-term expenses, and add value to their facilities while maintaining an aesthetic that aligns with modern architectural trends.

Share

Prev:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025