- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

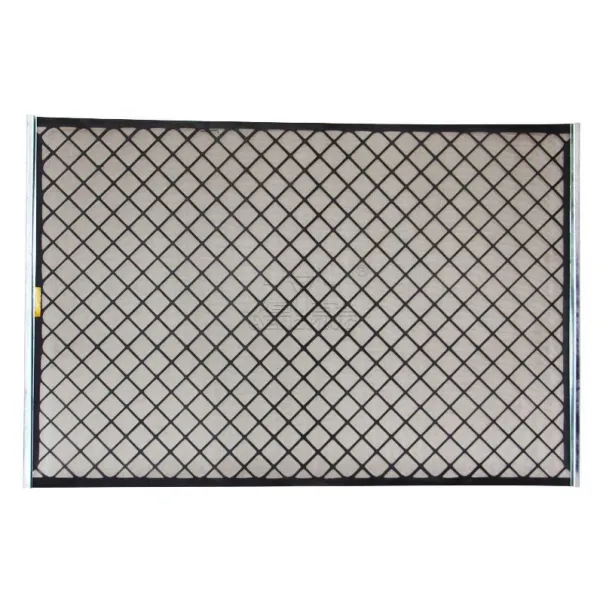

Innovative Design of 11w4 Bar Grating for Enhanced Structural Applications

Understanding the 11W4% Bar Grating Structure, Application, and Benefits

When it comes to construction and industrial applications, selecting the right materials is essential for ensuring safety, durability, and efficiency. One such material that has gained attention for various applications is the 11W4% bar grating. This article will explore its structure, applications, and the benefits of using 11W4% bar grating in numerous industries.

Structure of 11W4% Bar Grating

The term “11W4%” refers to a specific type of bar grating characterized by its unique frame and crossbar configuration. Typically, bar gratings are comprised of a series of parallel steel bars, welded or locked into place, creating a grid-like structure. The 11W indicates the spacing and orientation of the bars; specifically, it refers to the width and depth of the grating. The 4% signifies the percentage of open space within the grating, which affects its weight-bearing capacity and light penetration.

The manufacturing process typically involves hot-dip galvanization, which provides a protective zinc coating to the steel bars, enhancing corrosion resistance and overall lifespan. This treatment makes the grating suitable for various environments, including corrosive or wet conditions.

Applications of 11W4% Bar Grating

11W4% bar grating finds versatile uses across several industries. One of the most common applications is in flooring systems for industrial plants and commercial spaces. Its open-grid design allows for excellent drainage and ventilation, making it suitable for areas prone to spills or wet conditions. Additionally, it provides robust support for foot traffic while ensuring visibility of any underlying equipment or hazards.

Another prominent use of 11W4% bar grating is in walkways and platforms in facilities such as refineries, wastewater treatment plants, and chemical processing units. The lightweight yet strong composition allows for easy installation and accessibility, accommodating both personnel and machinery.

11w4 bar grating

Moreover, it is commonly used in the construction of stair treads. The non-slip surface reduces the risk of accidents in environments where water or chemicals might render surfaces slick. With its customizable options, 11W4% bar grating can be fabricated to fit specific dimensions or load requirements, making it a go-to choice for engineers and architects.

Benefits of Using 11W4% Bar Grating

There are several advantages to utilizing 11W4% bar grating in various applications. Firstly, its strength-to-weight ratio is impressive, allowing for substantial load-bearing capabilities without adding excessive weight to structures. This efficiency can lead to cost savings in both shipping and installation.

Another significant benefit is durability. The galvanization process protects against rust and corrosion, extending the lifespan of the grating in harsh environments. As such, organizations can reduce maintenance costs and improve the overall safety of their facilities.

Finally, the open design promotes excellent airflow and light transfer, creating safer and more pleasant working conditions. The ability to see through the grating also makes it easier to identify hazards below, enhancing safety protocols.

Conclusion

The 11W4% bar grating is a highly functional material that combines strength, durability, and versatility. Whether utilized in industrial flooring, walkways, or stair treads, its unique properties make it an invaluable asset across many sectors. Understanding its structure and applications empowers decision-makers to select the right materials for their specific needs, ultimately fostering safer and more efficient environments.

-

Welded Steel Bar Grating: The Strongest Choice for Industrial FlooringNewsMay.21,2025

-

Steel Grating for Sale: The Ultimate Anti-Slip SolutionNewsMay.21,2025

-

Steel Frame Shaker Screens: Unmatched Durability for Demanding OperationsNewsMay.21,2025

-

Shaker Screens: Your Ultimate Solution for Oil & Gas FiltrationNewsMay.21,2025

-

Press Locked Steel Grating: The Smarter Choice for Heavy-Duty FlooringNewsMay.21,2025

-

Helicopter Deck Safety Nets: Protect Your Crew and EquipmentNewsMay.21,2025