- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

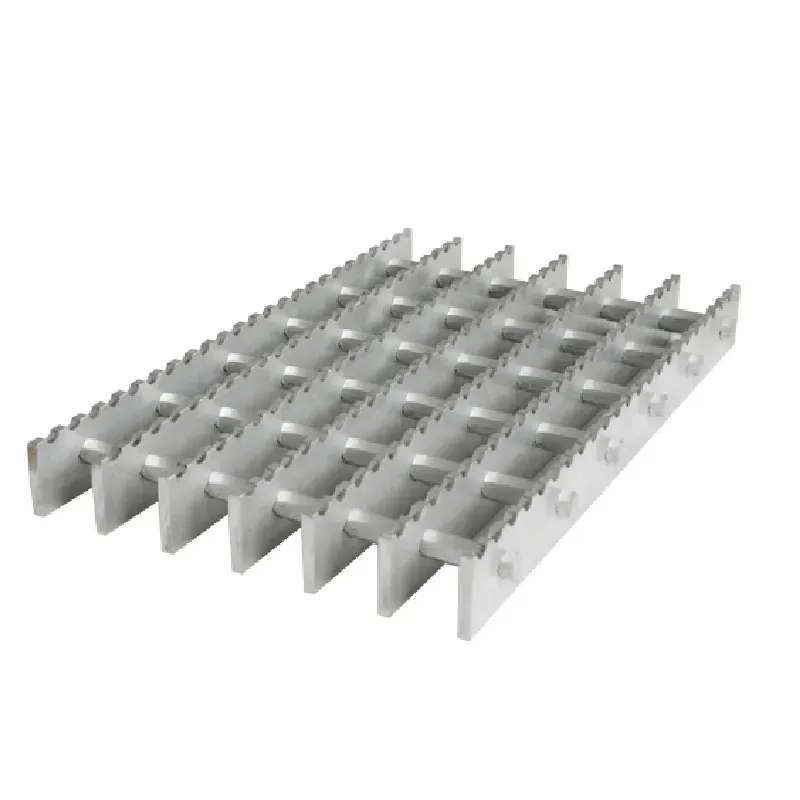

High-Quality Hot Dip Galvanized Steel Grating - Durable & Corrosion Resistant

- Introduction: Understanding Hot Dip Galvanized Steel Grating and Its Importance

- Technical Advantages and Performance Data of Hot Dip Galvanized Grating

- Comparative Analysis of Leading Manufacturers

- Custom Solutions Tailored to Project Needs

- Notable Application Scenarios and Case Studies

- Quality Control Measures and Industry Certifications

- Conclusion: The Future of Grating Hot Dip Galvanized Solutions

(hot dip galvanized steel grating)

Introduction: Understanding Hot Dip Galvanized Steel Grating

Hot dip galvanized steel grating represents a robust, long-lasting solution widely employed for industrial flooring, walkways, and platforms. This engineered steel grid system is formed by selecting high-tensile steel bars and processing them through a hot dip galvanization method. This ensures an even coat of molten zinc, permeating every point of contact and sealing the base metal from corrosive environments. The result is a durable and maintenance-efficient component, ideally suited for challenging climate and industrial conditions.

High-performance hot dip galvanized grating distinguishes itself due to its excellent mechanical properties combined with superior resistance to atmospheric corrosion. It remains a staple product in petrochemical plants, power stations, mining facilities, municipal infrastructures, and shipping docks. The grating hot dip galvanized variant continues to see rising demand, credited to its unmatched lifecycle value and compliance with rigorous safety codes across the globe.

Technical Advantages and Performance Data

The remarkable performance and durability of hot dip galvanized steel grating

largely stem from its technical attributes. The galvanization process provides a typical coating thickness of 70 to 100 microns, giving the steel an expected lifespan of over 30 years in moderate industrial settings. According to the American Galvanizers Association, hot dip galvanized surfaces can resist atmospheric corrosion rates as low as 1/30th that of bare steel.

Mechanical advantages include load-bearing capacities that can reach up to 245 kN/m2 for heavy-duty gratings, making them suitable for both foot and vehicular traffic. Additionally, slip resistance (Coefficient of Friction ≥ 0.36, per ASTM F1637-13) is integrated into various surface finishes. Uniform bar spacing ensures reliable drainage and ventilation, reducing the accumulation of hazardous substances.

| Parameter | Hot Dip Galvanized Grating | Paint-Coated Grating | Plain Steel Grating |

|---|---|---|---|

| Lifespan (years) | 30+ | 8-12 | 3-5 |

| Corrosion Resistance | Excellent | Moderate | Poor |

| Maintenance Frequency | Low | Medium | High |

| Load Capacity (kN/m2) | Up to 245 | Up to 180 | Up to 120 |

As demonstrated in the table above, hot dip galvanized steel grating dramatically outperforms both painted and plain steel alternatives across all crucial metrics, reflecting its status as the premier choice for critical infrastructure applications.

Comparative Analysis of Leading Manufacturers

When sourcing hot dip galvanized grating, the choice of a manufacturing partner influences project timelines, documentation, and product consistency. Major players in the sector include Nucor Grating, Webforge, Lionweld Kennedy, and regional suppliers serving specific market zones. These producers adhere to standards such as ISO 9001, EN 1090, and ASTM A123/A123M, guaranteeing visual, dimensional, and functional conformity.

Manufacturers distinguish themselves based on production capacity, bar pressure welding accuracy, inventory breadth, customization flexibility, and delivery logistics. While large-scale producers may offer economies of scale and faster standard lead times, niche providers may feature enhanced customization and value-add engineering support.

| Manufacturer | Annual Output (tons) | Customization Level | Lead Time (days) | Compliance |

|---|---|---|---|---|

| Nucor Grating | 16,500 | Medium | 20-28 | ASTM, ISO |

| Webforge | 18,000 | High | 15-25 | EN, ISO |

| Lionweld Kennedy | 10,000 | High | 18-26 | ISO, BS |

| Regional Supplier | 4,000 | Very High | 12-22 | Custom |

The industry landscape rewards precise specification, reliable delivery, and after-sales support. Selection should also factor in track record and the ability to integrate emerging technologies into production such as automated welding or digital project modeling.

Custom Solutions Tailored to Project Needs

No two environments demand the same steel grating solution. While standard configurations (serrated or plain bars, fixed pitch, and panel sizes) are readily available, many clients seek customized solutions to optimize safety, performance, or aesthetics. Standard load tables offer guidance, but specialists routinely craft tailored hot dip galvanized grating—including thickened bearing bars, different surface serrations, or bespoke edging treatments.

Solutions can be designed for unique traffic loads, hazardous environments, or architectural requirements. For instance, industrial clients in chemical processing frequently request additional post-galvanization coatings for extreme environments, while commercial projects may prioritize bespoke shaping and finishes for integration with landscape design. Project managers should collaborate early with technical consultants to maximize both product and process efficiencies.

- Variable panel sizes and unusual geometric layouts

- Adjustable bar spacing for load or drainage requirements

- Specialized anti-slip or anti-static surfaces

- Integrated fastening and locking mechanisms

- Color-matched or double-hot-dipped options for highly corrosive sites

Notable Application Scenarios and Case Studies

The versatility of grating hot dip galvanized solutions is showcased across sectors. In the energy sector, platforms made with hot dip galvanized grating withstand the corrosive atmosphere of offshore oil rigs for decades. Data from a 2023 offshore survey indicates that over 80% of access platforms in the surveyed North Sea installations utilize hot dip galvanized steel grating, highlighting its long-term reliability.

In municipal infrastructure, city bridges and drainage covers demand lasting strength and minimal service interruption. For example, a major Eastern European city retrofitted its river-spanning pedestrian bridges with hot dip galvanized gratings in 2017—inspection data in 2022 showed zero recorded corrosion or structural compromise, despite harsh winters and intensive pedestrian use.

Mining and heavy industry sectors rely on both custom-fabricated and standard grating types. A mining company in Chile reported a 47% drop in walkway maintenance costs following a switch from painted steel to hot dip galvanized panels across a 250,000 m2 processing plant infrastructure.

Quality Control Measures and Industry Certifications

Ensuring the structural and surface integrity of each grating panel is essential. Leading manufacturers deploy multi-stage quality control, beginning with raw material inspection (yield strength, elongation, and chemical composition) and culminating in post-galvanization audits for uniformity, thickness, and coating adhesion.

Batch testing follows protocols such as ASTM E376 and EN ISO 1461, and non-destructive testing methods like ultrasonic thickness measurement are routinely applied. Most reputable suppliers are certified under ISO 9001 for quality management, and maintain compliance with sector-specific standards (EN 1090 for CE marking, ASTM for the American market). In addition, environmental compliance is increasingly relevant, with lifecycle assessments and low-emission production gaining market attention.

- Regular adherence to global and local fabrication standards

- Documented traceability for every production batch

- Third-party inspection and laboratory testing

- Continuous improvement initiatives for waste reduction

Conclusion: The Future of Hot Dip Galvanized Steel Grating

Hot dip galvanized steel grating continues to redefine standards for industrial and public infrastructure. Its proven resilience, low lifecycle costs, and adaptability to new technological advances position it as the material of choice for forward-thinking projects worldwide. As environmental demands intensify, developments such as advanced galvanizing alloys, digital fabrication controls, and circular material use will further cement the leadership of grating hot dip galvanized products in both classic and emerging applications.

In summary, decision-makers seeking optimal performance under tough operational demands consistently turn to hot dip galvanized grating solutions for proven endurance and innovation-driven value, ensuring safety and efficiency across a diverse array of challenging environments.

(hot dip galvanized steel grating)

FAQS on hot dip galvanized steel grating

Q: What is hot dip galvanized steel grating?

A: Hot dip galvanized steel grating is a type of grating made from steel bars that are coated with zinc through a hot dip process. This provides strong corrosion resistance and durability. It is commonly used in industrial and commercial flooring applications.Q: What are the benefits of using hot dip galvanized grating?

A: Hot dip galvanized grating offers excellent rust resistance and a long service life. The zinc coating protects the steel from harsh environments. It also provides a non-slip surface for safety.Q: Where can grating hot dip galvanized be used?

A: Grating hot dip galvanized is suitable for walkways, platforms, drainage covers, and stair treads. It is widely used in factories, power plants, and public infrastructure. Its durability makes it ideal for outdoor and industrial use.Q: How is hot dip galvanized grating maintained?

A: Hot dip galvanized grating requires minimal maintenance due to its protective zinc layer. Regular inspection and occasional cleaning keep it in optimal condition. Repairs are rarely needed unless the coating is physically damaged.Q: How is hot dip galvanized steel grating installed?

A: Installation usually involves fixing the grating to supporting structures using clips or welding. The process is quick and does not require complicated tools. This ensures a secure and stable fit for various applications.-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025