- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

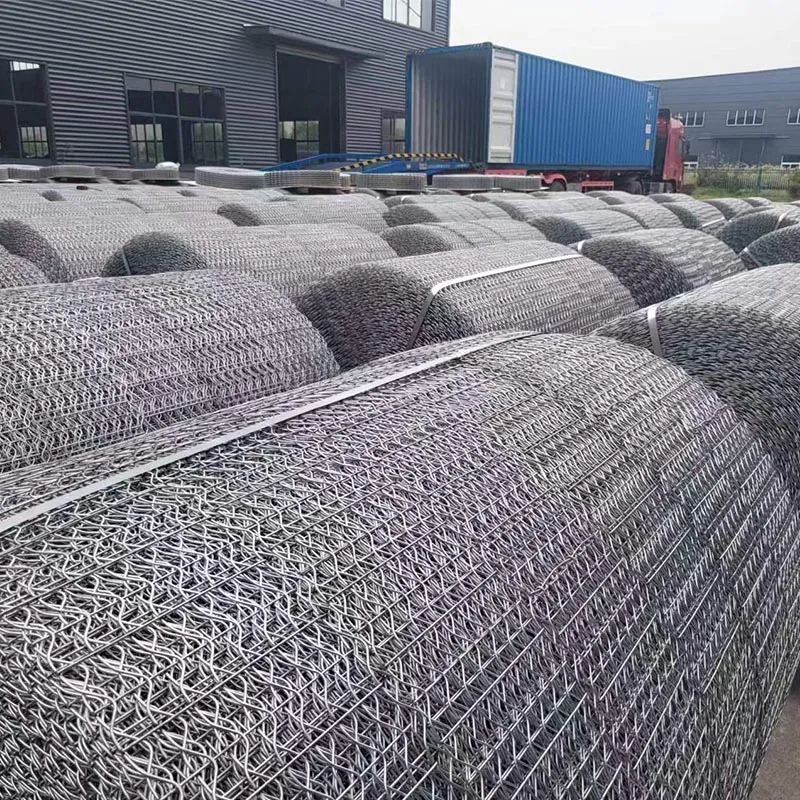

galvanised floor grating

Galvanized Floor Grating An Overview

Galvanized floor grating has become a popular choice in various industrial and commercial applications due to its durability, safety features, and cost-effectiveness. This versatile material can be found in many environments, from manufacturing plants to outdoor walkways, and even in architectural designs. In this article, we will explore the benefits, applications, and installation processes associated with galvanized floor grating.

What is Galvanized Floor Grating?

Galvanized floor grating is a type of flooring material made from steel bars that are welded together to form a grid-like structure with openings. The galvanized part refers to the protective coating applied to the steel through a hot-dip galvanization process, which involves immersing the metal in molten zinc. This coating helps prevent rust and corrosion, making galvanized floor grating suitable for both indoor and outdoor use.

Benefits of Galvanized Floor Grating

1. Durability The galvanization process significantly improves the lifespan of the metal, protecting it from harsh environmental conditions, moisture, and chemicals. This durability means that galvanized floor grating can withstand heavy loads and frequent foot traffic without compromising its structural integrity.

2. Safety Galvanized grating provides excellent drainage and slip resistance, making it an ideal choice for areas where water, oil, or other substances may create slippery surfaces. Its open design allows for quick drainage, reducing the risk of accidents in both industrial and commercial settings.

3. Cost-Effectiveness While the initial investment in galvanized floor grating may be higher than some other flooring options, its longevity and low maintenance requirements make it a more cost-effective choice in the long run. The need for frequent replacements or repairs is minimized, which can lead to significant savings over time.

4. Customization Galvanized floor grating can be customized to fit various needs and specifications. It comes in different sizes, thicknesses, and patterns, allowing it to suit a wide range of applications, including pedestrian walkways, industrial flooring, and more.

5. Eco-Friendly The galvanization process is environmentally friendly as it uses recyclable materials, and the longevity of the product reduces the need for replacements, ultimately leading to less waste.

Applications of Galvanized Floor Grating

Galvanized floor grating is used in numerous industries and applications, including

- Manufacturing In factories and plants, galvanized floor grating provides safe working environments, allowing for easy movement of equipment and personnel while facilitating proper drainage

.galvanised floor grating

- Commercial Spaces Many shopping centers and commercial buildings utilize galvanized grating for walkways, staircases, and platforms due to its safety features and aesthetic appeal.

- Outdoor Settings Parks, recreational areas, and even residential landscaping can benefit from the installation of galvanized grating, which can be used in boardwalks, bridges, and drainage covers.

- Marine Applications The resistance to corrosion makes galvanized floor grating suitable for use in marine environments where exposure to saltwater is common.

Installation Process

Installing galvanized floor grating is a straightforward process but requires careful consideration of the design and layout. The basic steps typically include

1. Planning and Measurement Proper planning and accurate measurement of the installation area are crucial to ensure a correct fit.

2. Preparation The surface should be prepared adequately, ensuring it is level and free from debris.

3. Cutting If necessary, the grating panels should be cut to size using appropriate tools, taking care to avoid damaging the galvanized coating.

4. Securing The panels are then secured in place using bolts, clips, or other fastening methods, depending on the specific application.

5. Final Inspection A thorough inspection is important to ensure that everything is installed correctly and safely.

Conclusion

In summary, galvanized floor grating is an essential material that offers a blend of durability, safety, and cost-effectiveness. Its versatility allows for a wide range of applications, making it a preferred choice in many sectors. Whether for industrial use or commercial spaces, galvanized floor grating provides a reliable solution that stands the test of time.

-

Welded Steel Bar Grating: The Strongest Choice for Industrial FlooringNewsMay.21,2025

-

Steel Grating for Sale: The Ultimate Anti-Slip SolutionNewsMay.21,2025

-

Steel Frame Shaker Screens: Unmatched Durability for Demanding OperationsNewsMay.21,2025

-

Shaker Screens: Your Ultimate Solution for Oil & Gas FiltrationNewsMay.21,2025

-

Press Locked Steel Grating: The Smarter Choice for Heavy-Duty FlooringNewsMay.21,2025

-

Helicopter Deck Safety Nets: Protect Your Crew and EquipmentNewsMay.21,2025