- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

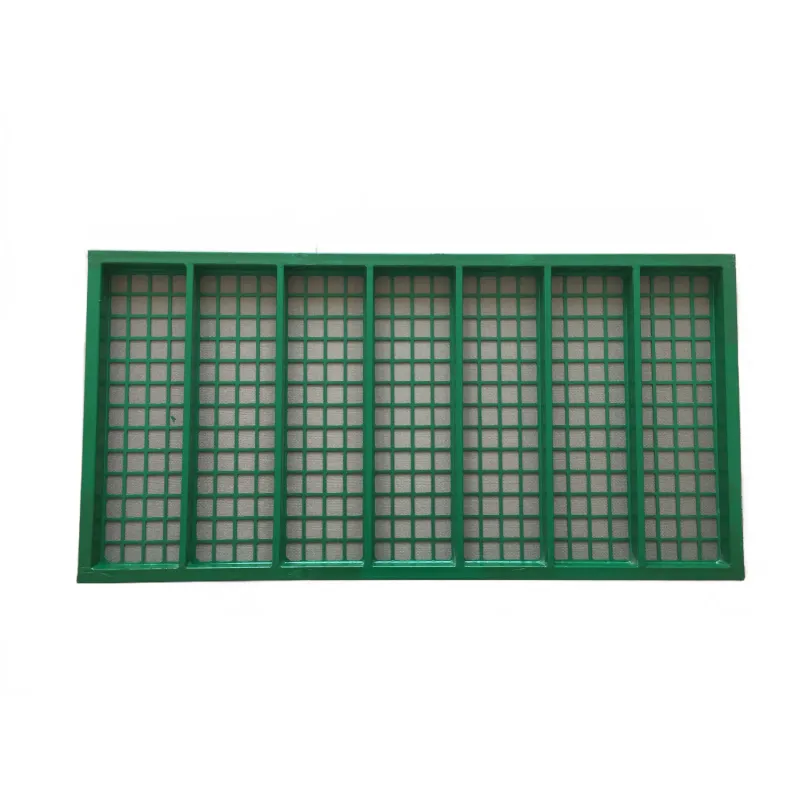

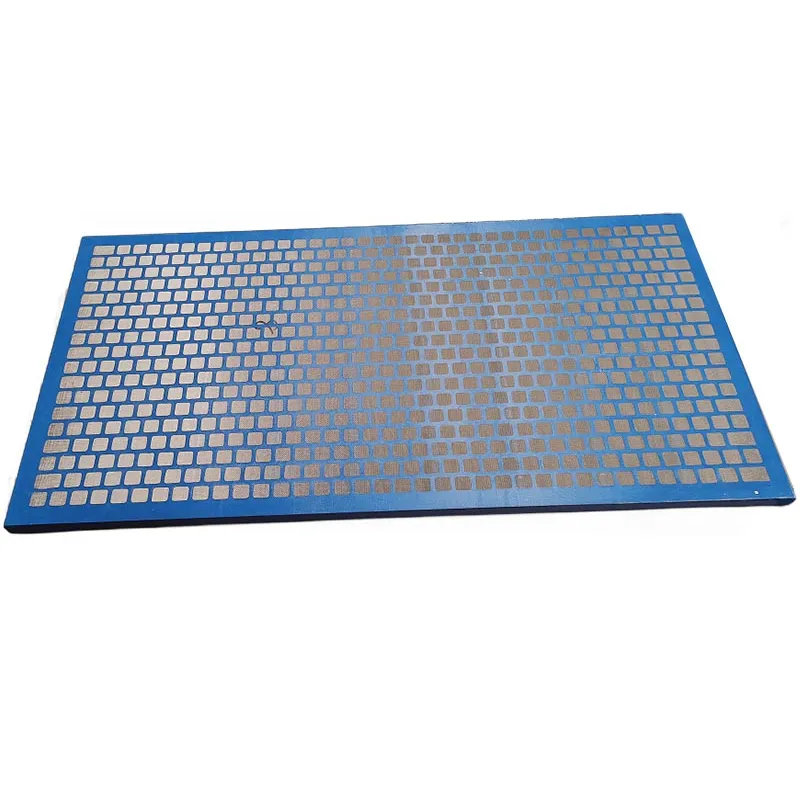

Durable Steel Frame Shale Shaker Screen | High-Efficiency, Long-Lasting

Industry-Leading Manufacturer

Anping County Hangshun Wire Mesh Manufacture Co., Ltd specializes in advanced drilling filtration solutions.

- Website: https://www.hfpetromesh.com

- Email: sales@hfpetromesh.com

- Phone: +86-18931809706

- Address: Industrial zone, South of Anping Town, Hengshui, Hebei, China

Introduction to Steel Frame Shale Shaker Screens

The petroleum drilling industry relies on critical separation technology where the Steel Frame Shale Shaker Screen plays an indispensable role. As primary solid control equipment, these screens use precise mesh configurations mounted on rigid steel supports to efficiently separate drill cuttings from drilling fluid. The incorporation of high-strength steel frames addresses critical challenges of vibration resistance, structural integrity, and longevity under extreme operational conditions.

According to research published in the Journal of Petroleum Exploration and Production Technology, the enhanced structural stability of steel-frame screens reduces screen deformation by 40-60% compared to traditional alternatives, significantly contributing to consistent filtration performance during extended drilling operations.

Product Spotlight

Premium Steel Frame Shale Shaker Screen

Description: Engineered with robust steel support structures and precision mesh layers, our Steel Frame Shale Shaker Screen delivers exceptional filtration efficiency in demanding oilfield operations. Manufactured to exceed API RP 13C standards, these screens maintain consistent performance across various drilling environments.

Technical Specifications

| Parameter | Value Range | Industry Standard | Significance |

|---|---|---|---|

| Mesh Count | 20-325 mesh | API RP 13C | Determines particle separation capability |

| Frame Material | High-tensile steel | ASTM A36/A572 | Provides structural stability under vibration |

| Dimensions | Customizable up to 1,500×700mm | OEM Specifications | Compatibility with shaker models |

| Maximum G-force | Up to 10G | ISO 13501 | Vibration resistance capability |

| Screen Life | 120-250 hours | API 13A/13B | Operational longevity |

Industrial Applications

The Steel Frame Shale Shaker Screen serves vital functions across multiple drilling scenarios:

Onshore Drilling Operations

Traditional drilling environments where consistent performance under continuous operation is required. Steel Frame Shale Shaker Screens withstand the abrasive wear from formations like sandstone and shale.

Offshore Drilling Platforms

High-pressure environments with significant vibration challenges. The rigid steel construction prevents structural deformation under maritime drilling conditions.

Directional Drilling

Extended-reach applications with high solids contamination. Steel Frame Shale Shaker Screens maintain filtration precision across varying fluid densities.

Geothermal Drilling

High-temperature applications that demand exceptional heat resistance from screening equipment. Our specialized thermal-resistant adhesives ensure bonding integrity under extreme conditions.

The Society of Petroleum Engineers notes that proper screen selection accounts for up to 40% of drilling fluid management efficiency in challenging operations (SPE Source).

Professional FAQ: Steel Frame Shale Shaker Screens

Q: What material composition optimizes corrosion resistance?

A: Our screens utilize 316L stainless steel with added molybdenum for chloride resistance in offshore operations. The welding process prevents corrosion at joint points which increases typical screen lifespan by 30-50%.

Q: How does mesh layering affect screening efficiency?

A: Multilayer construction utilizes progressively finer meshes to prevent blinding while maintaining flow rates. Research from the OnePetro technical library demonstrates tri-layer screens achieve 92-98% solids removal efficiency compared to 70-85% in single-layer alternatives.

Q: What temperature range can these screens withstand?

A: Standard Steel Frame Shale Shaker Screens operate reliably between -20°C to 120°C. High-temperature variants using specialized adhesives maintain structural integrity up to 150°C for geothermal applications.

Q: How do bonding techniques affect screen longevity?

A: We utilize thermal fusion bonding rather than chemical adhesives. This creates molecular-level bonds that withstand vibration better and eliminate glue degradation issues that reduce screen life.

Q: What installation considerations are critical?

A: Proper tensioning during installation is essential. Our screens feature reinforced tensioning rails that allow for ±1mm tolerance adjustment to prevent sagging which accelerates mesh wear.

Q: How does frame geometry impact fluid throughput?

A: Aerodynamic channel design reduces fluid impedance by 18-22% compared to standard frames. This maintains target flow rates of 200-400 GPM without compromising solids removal efficiency.

Q: What maintenance procedures extend service life?

A: Regular visual inspections for mesh tears, tension verification, and immediate replacement of damaged panels. Proper cleaning procedures prevent premature clogging which accounts for 60% of early screen failures according to IADC reports.

Industry Trends and Technological Evolution

Recent innovations in Steel Frame Shale Shaker Screen technology focus on advanced composite materials that maintain structural strength while reducing weight. The integration of non-metallic composite reinforcement reduces vibration-induced fatigue by up to 30% while decreasing weight by 15-20%, according to research published in the SPE Journal of Petroleum Technology.

Digital monitoring systems represent another emerging trend where sensors embedded in screen frames track operational parameters including vibration frequency, mesh deformation, and stress points. This predictive maintenance technology alerts operators to potential failures before downtime occurs. Current industry estimates project that predictive maintenance applications could reduce drilling operational costs by 8-12% annually within the next five years.

Eco-design innovations have recently gained prominence where recyclability considerations now guide screen manufacturing processes. Our company utilizes 92% recyclable steel components which significantly reduces the environmental footprint of replacement programs. The 2023 Global Drilling Sustainability Report highlights how waste reduction initiatives in solids control equipment can contribute to 3-5% reductions in overall drilling environmental impact.

Optimize Your Drilling Operations

The advanced Steel Frame Shale Shaker Screen technology from Anping County Hangshun delivers unparalleled structural stability and filtration efficiency. Our engineering expertise and commitment to API standards ensure optimal performance across diverse drilling environments.

Research References

- Society of Petroleum Engineers. (2024). "Advances in Solids Control Technology." SPE Drilling & Completion Journal. https://www.spe.org/

- International Association of Drilling Contractors. (2023). "Best Practices in Screen Selection & Maintenance." Technical Report 2023-4. https://www.iadc.org/

- Petroleum Technology Quarterly. (2024). "Global Shale Shaker Screen Market Analysis 2024-2030." https://www.ptq.pemedia.com/

- Oilfield Technology Magazine. (2023). "Material Innovations in Drilling Filtration Systems." Vol. 20(3). https://www.oilfieldtechnology.com/

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025