- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

what size does steel grating come in

Understanding Steel Grating Sizes

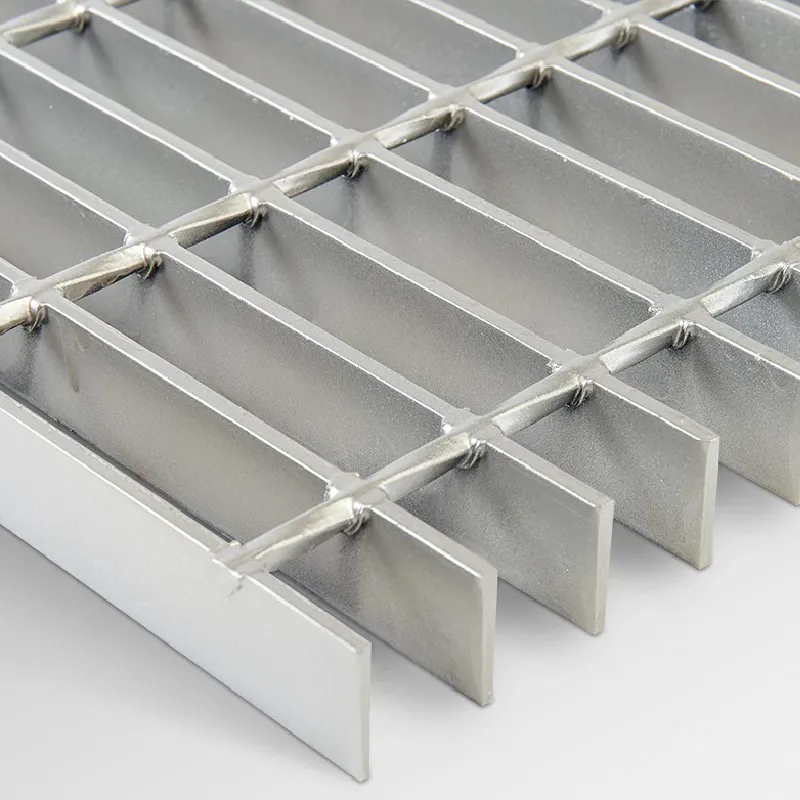

Steel grating is a widely used material in various industries due to its durability, strength, and versatility. It is commonly employed in areas such as construction, manufacturing, and infrastructure, often serving purposes like flooring, walkways, and drainage covers. However, when considering the use of steel grating, one of the most crucial factors to understand is the sizes that it comes in. This article will explore the various dimensions and specifications related to steel grating.

Standard Sizes of Steel Grating

Steel grating is available in numerous standard sizes, which can vary based on the manufacturer and specific application. Typically, the most common dimensions for steel grating panels are 24 inches by 48 inches, 30 inches by 30 inches, and 36 inches by 48 inches. These standard sizes allow for easier installation and compatibility with various structural frameworks.

In addition to dimensions, the thickness of the steel grating also plays a vital role. Common thicknesses range from 1/4 inch to 1 inch, with the choice often dependent on the load-bearing requirements of the application. Thicker grates are generally used in heavy-duty applications, such as industrial settings, while thinner options might suffice for pedestrian walkways.

Types of Steel Grating Profiles

While size is important, it's equally essential to consider the profile of steel grating. The most prevalent types include

1. Bar Grating The most common form, characterized by parallel bars spaced evenly apart. Bar grating can be made using various materials, such as carbon steel or stainless steel, and comes in different spacing options, typically 1 inch, 1-1/2 inch, or 2 inches.

what size does steel grating come in

2. Expanded Metal Grating This type is made from sheets of metal that are cut and stretched to create a mesh-like surface. It is noted for its slip-resistant properties, making it an excellent choice for walkways and stairways.

3. Trench Grating Used in drainage applications, trench grating is designed to cover drainage channels or trenches. It usually comes in sizes that fit standard trench widths and depths.

4. Heavy-Duty Grating This type is designed for applications that require extra strength and support, such as loading docks and industrial environments. It is typically thicker and made from high-strength materials.

Custom Sizes and Special Considerations

In addition to standard sizes, many manufacturers offer custom sizes to meet specific project requirements. Custom fabrication allows for modifications in dimensions, thickness, and bar spacing, which can be essential for unique architectural designs or specialized applications.

When selecting steel grating, it’s crucial to consider its load capacity, corrosion resistance, and any specific industry standards that need to be met. For instance, industries like oil and gas may have unique specifications for safety and durability.

Conclusion

Understanding the various sizes and types of steel grating is essential for selecting the right product for your needs. With standard dimensions readily available and options for custom sizes, there is a broad range of choices in the market. By assessing your application requirements—including load-bearing needs, environmental conditions, and safety standards—you can ensure that you select the appropriate steel grating that not only meets but exceeds your expectations.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025