- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

steel grating thickness

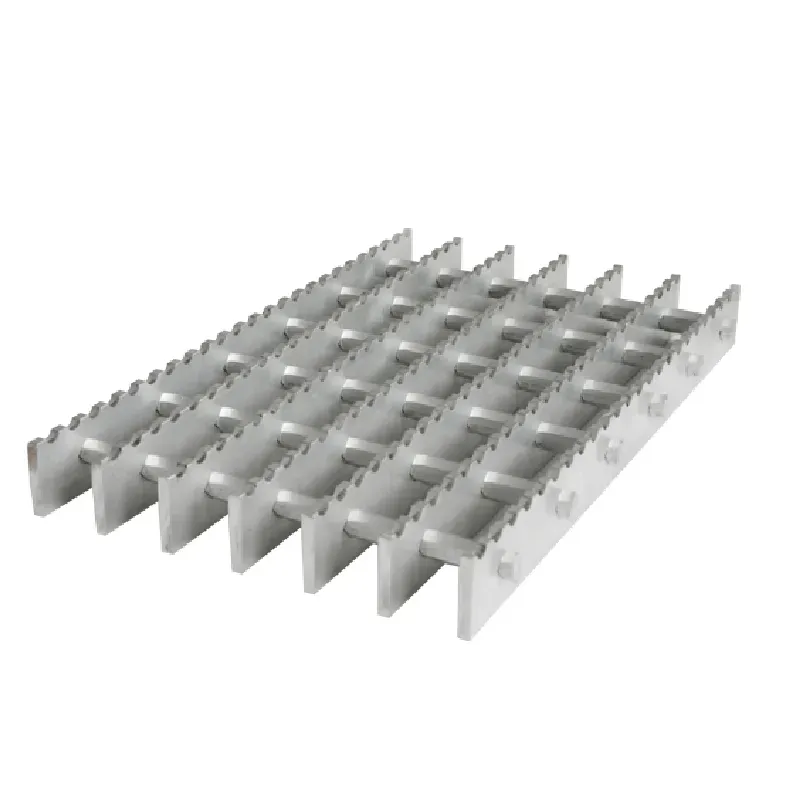

Understanding Steel Grating Thickness A Comprehensive Guide

Steel grating is a versatile material widely used across various industries, from construction to manufacturing, due to its strength, durability, and ability to provide superior drainage and ventilation. One of the crucial specifications when choosing steel grating is its thickness, which significantly impacts the performance, load-bearing capacity, and overall utility of the grating in specific applications. In this article, we will delve into the importance of steel grating thickness, factors influencing it, and how to select the appropriate thickness for your needs.

Importance of Steel Grating Thickness

The thickness of steel grating affects several key aspects of its performance

1. Load-Bearing Capacity Thicker grating can support heavier loads without bending or breaking. This is particularly important in industrial settings where heavy machinery and equipment are used. The load-bearing capacity is often quantified by the grating’s span and thickness; thicker grating can typically accommodate a larger span while supporting greater weights.

2. Durability and Longevity Thicker steel grating is usually more resistant to wear and tear, making it ideal for high-traffic areas or environments exposed to harsh conditions. It can withstand impacts from falling objects, heavy foot traffic, and exposure to chemicals, extending its lifespan and reducing the need for frequent replacements.

3. Safety A thicker grating can provide better safety features. For instance, in environments where slipping can pose a risk, thicker grating angled with a slip-resistant finish can enhance traction, minimizing the likelihood of accidents.

4. Acoustic Properties In settings where noise reduction is necessary, the thickness of the grating can influence sound dampening. Thicker materials can absorb sound better, leading to a quieter environment, which is essential in places like concert venues or libraries.

Factors Influencing Steel Grating Thickness

When selecting the appropriate thickness for steel grating, several factors should be considered

1. Application Purpose The intended use of the grating plays a significant role. For example, grating used in heavy industrial applications will require greater thickness compared to that used for walkways in commercial buildings.

steel grating thickness

2. Environmental Conditions The environmental conditions the grating will be exposed to can influence the choice of thickness. Areas prone to heavy snowfall or rain might necessitate thicker gratings to handle additional weight and prevent deformation.

3. Span The distance between supports needs to be factored in. The greater the span, the thicker the grating should be to prevent sagging or bending under load.

4. Material Specifications Different grades of steel have varying strength characteristics. Depending on the type of steel used (e.g., carbon steel, stainless steel), a thinner grating may suffice in some cases while still maintaining the necessary strength.

5. Weight Considerations Thicker grating means more weight. In some applications, notably in roof or elevated structures, the additional weight might be a concern. It’s crucial to balance the need for durability with structural integrity.

Selecting the Right Thickness

To select the right thickness for your steel grating, it is advisable to conduct a thorough analysis of your project's requirements. Here are some steps to guide the decision-making process

1. Define the Load Determine the maximum weight expected on the grating. This information will help in selecting a thickness that meets or exceeds these requirements.

2. Consult Standards Refer to industry standards and guidelines governing steel grating specifications. Organizations such as the American National Standards Institute (ANSI) offer extensive resources detailing recommended specifications.

3. Engage with Experts Consulting with grating manufacturers or structural engineers can provide insights into the best choices for your specific application, ensuring that you make an informed decision.

4. Consider Future Needs Anticipate future changes in load requirements. If additional machinery will be introduced or if the application may change, opting for a thicker grating initially may save costs down the line.

In conclusion, the thickness of steel grating is a vital aspect that influences its functionality and performance across various applications. Understanding the factors that affect your choice will ensure you select the appropriate specifications, thereby enhancing safety, durability, and cost-effectiveness in your projects. Whether you are designing a new industrial platform or selecting walkways for public spaces, paying attention to steel grating thickness will ultimately lead to better outcomes.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025