- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

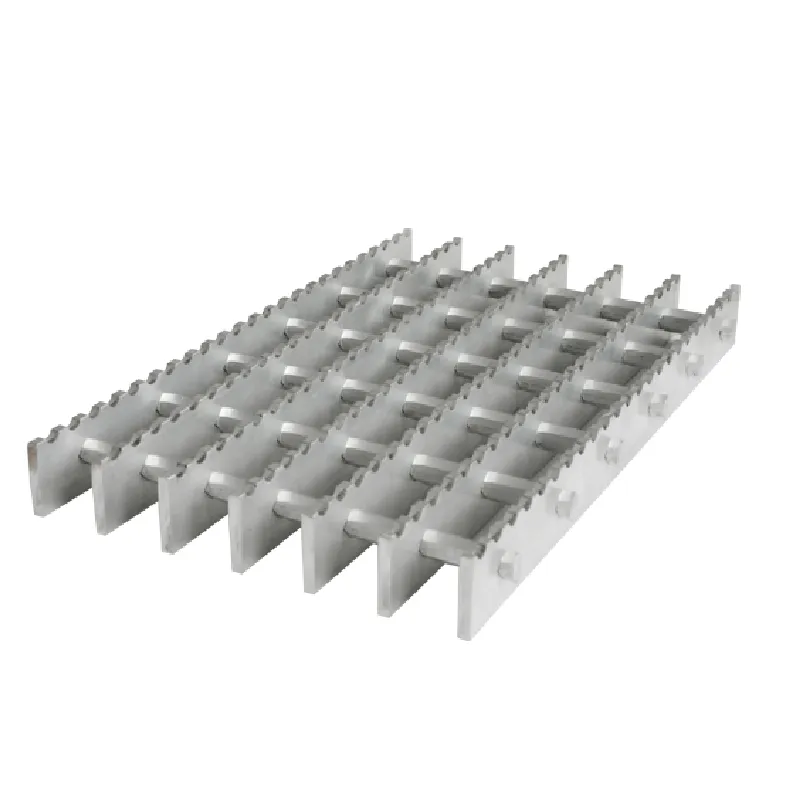

Specifications and Guidelines for Steel Grating Design and Installation Practices

Steel Grating Specifications A Comprehensive Guide

Steel grating is an essential component in a wide variety of industrial and commercial applications. Its unique design and strength make it ideal for numerous uses, including flooring, walkways, ramps, and more. Understanding steel grating specifications is crucial for selecting the right type for your project, ensuring safety, durability, and efficiency. This article will delve into the specifications of steel grating, covering everything from materials to types and load-bearing capacities.

Materials Used in Steel Grating

Steel grating is primarily made from carbon steel, stainless steel, or galvanized steel. Each material offers distinct advantages

1. Carbon Steel Known for its strength and cost-effectiveness, carbon steel is often used in areas where corrosion is not a significant concern. It is widely used in industrial applications but should be painted or coated to improve its corrosion resistance.

2. Stainless Steel This material is ideal for environments with high moisture or corrosive agents, such as chemical plants, food processing facilities, and marine environments. Although more expensive than carbon steel, stainless steel’s resistance to corrosion and ease of cleaning often justify the investment.

3. Galvanized Steel This type of steel is coated with zinc to protect against rust and corrosion. Galvanized steel grating is versatile and can be used in various outdoor applications where moisture exposure is a concern.

Types of Steel Grating

There are several types of steel grating, each designed to meet specific load-bearing and application requirements. The most common types include

1. Standard Steel Grating This is the most common type and is used extensively in industrial environments. It has a simple grid design, with load-bearing bars running parallel to each other, providing stability and ease of installation.

2. Heavy-Duty Grating Designed for applications that require higher load capacities, heavy-duty grating uses thicker materials and closely spaced bearing bars. It's often used in areas with heavy foot traffic or where wheeled equipment operates.

steel grating specifications

3. Architectural Grating This type is typically used in commercial settings where aesthetics are as important as functionality. Architectural grating can have varying designs, colors, and finishes, providing a more visually appealing option for public spaces.

4. Drainage Grating Often found in urban environments, drainage grating is designed to allow water to flow freely while supporting pedestrian traffic. This type of grating is essential for maintaining proper drainage and preventing flooding in areas like sidewalks and parking lots.

Load-Bearing Capacity and Safety

One of the critical aspects of steel grating specifications is load-bearing capacity. It refers to the maximum weight the grating can support without deformation or failure. Load ratings are typically classified using the following designations

- Light Duty Suitable for pedestrian foot traffic, with a load-bearing capacity of around 250 lbs. - Medium Duty Designed to support moderate loads, such as small wheeled equipment, with a capacity of 500 lbs. - Heavy Duty Capable of supporting significant loads like forklifts and larger vehicles, with capacities exceeding 1,000 lbs.

When selecting steel grating, it is crucial to consider the expected load and choose a grating type that meets or exceeds this requirement. Additionally, it is essential to adhere to local building codes and safety regulations to ensure compliance and minimize risks.

Surface Treatments and Finishes

The surface of steel grating can be treated or finished in various ways to enhance its durability and safety. Common surface treatments include

- Hot-Dip Galvanization Provides excellent corrosion resistance for outdoor applications. - Painted Finish Ideal for aesthetically pleasing applications, can be applied to any type of steel grating. - Slip-Resistant Coatings Essential for enhancing safety, these coatings provide additional grip on the surface, reducing the risk of slips and falls.

Conclusion

Understanding steel grating specifications is vital for making informed decisions regarding your project requirements. By considering factors such as materials, types, load-bearing capacities, and surface treatments, you can select the most appropriate steel grating that meets the necessary safety, durability, and aesthetic standards. Whether you're working on a large-scale industrial project or a smaller commercial application, having the right steel grating solution will ultimately ensure the success and safety of your venture.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025