- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Premium Metal Grating for Sale - Durable & Custom Solutions

The global demand for industrial flooring and safety platforms is experiencing robust growth—with steel grating markets projected to reach USD 2.1 billion by 2027 (Markets&Markets report). As the need for durable, maintenance-friendly, and customizable industrial flooring rises, metal grating for sale has become a crucial keyword for project engineers and procurement professionals across industries.

This article provides a comprehensive review of steel grating solutions, focusing on the high-performance metal grating for sale from Swage-Locked Steel Grating. We analyze technological parameters, industry applications, manufacturing processes, vendor comparisons, customization, case studies, and FAQ for all seeking to buy steel grating.

Market Overview: Trends & Growth Drivers for Metal Grating For Sale

- Industrial construction and safety codes (e.g. OSHA, ANSI) fuel demand for robust steel grating solutions worldwide.

- Shift toward carbon steel grating and galvanized options due to their cost-effectiveness and strength-to-weight ratios.

- Customization for project-specific loads, anti-slip surfaces, and anti-corrosive coatings—spanning types of steel grating from swage-locked to press-locked and welded bar grating.

- Key industries: Petrochemical, Metallurgy, Water Treatment, Mining, Power, Shipbuilding.

- Asia-Pacific dominates supply, with North America and Europe focusing on compliance and top-tier industrial standards.

Main Product Introduction:

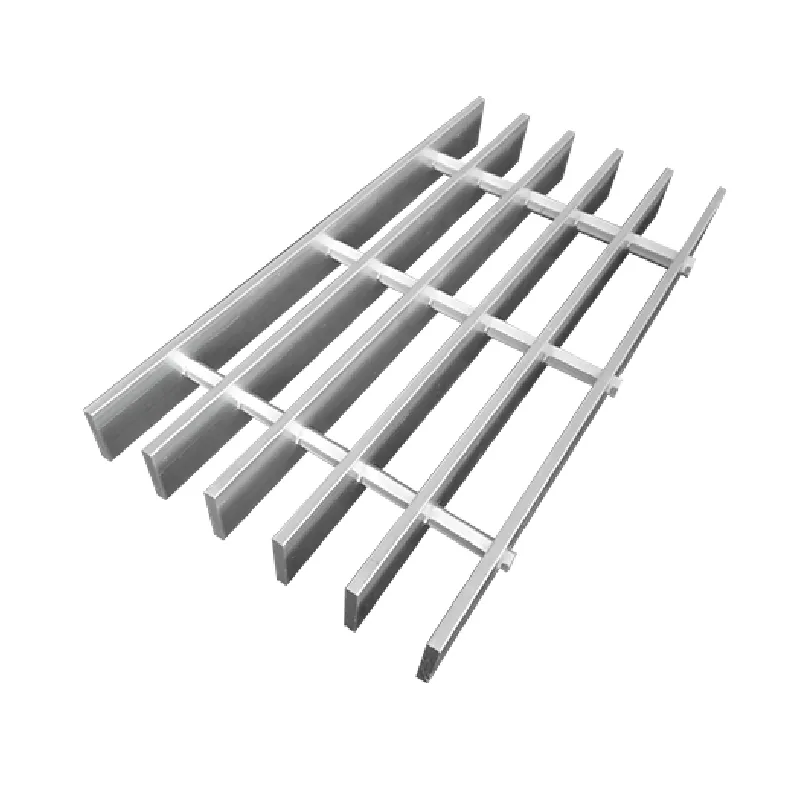

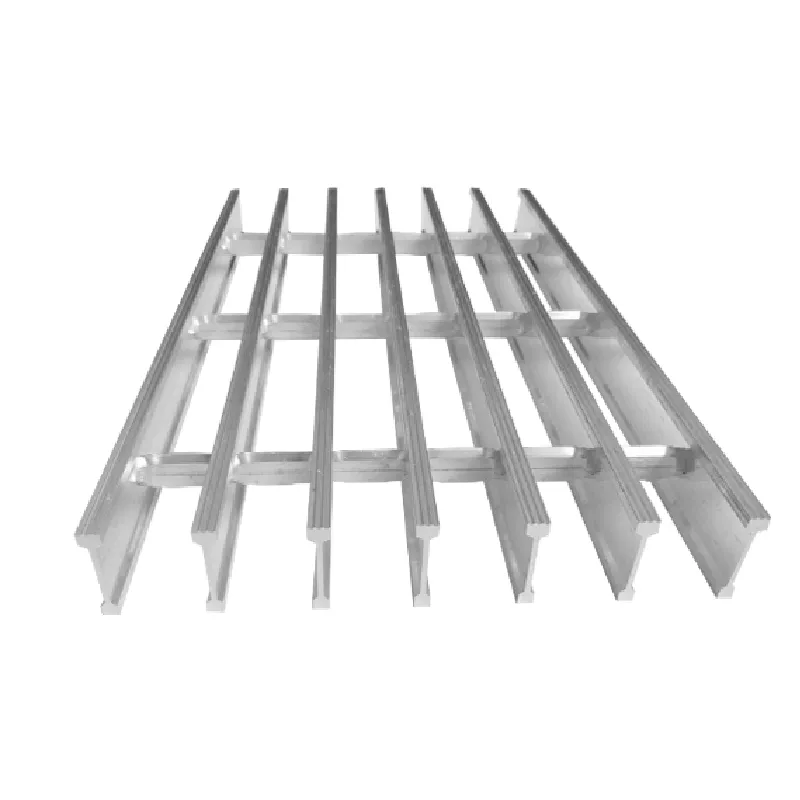

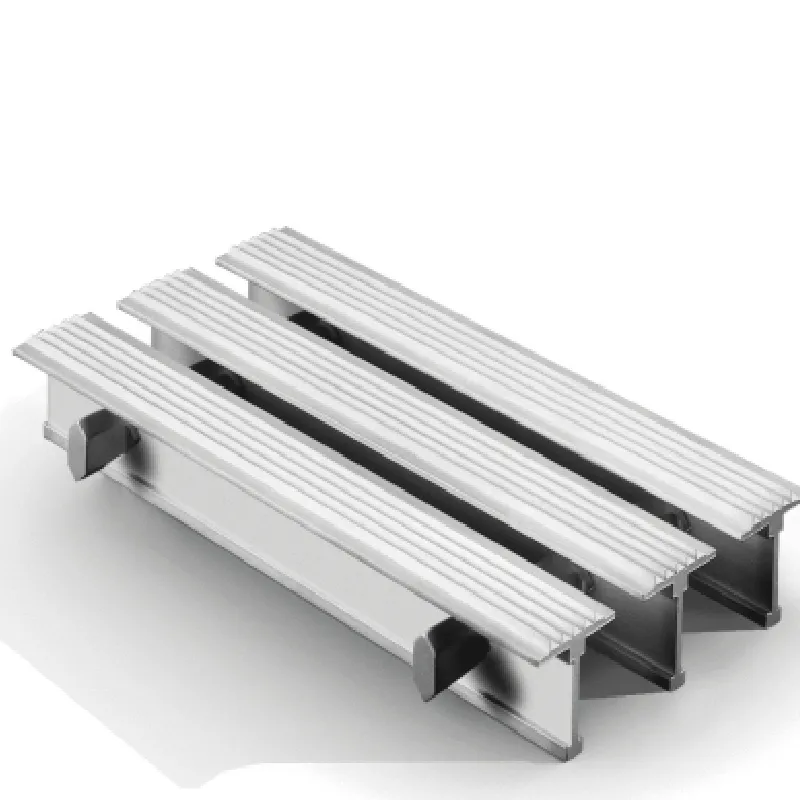

Swage-Locked Steel Grating

Swage-Locked Steel Grating is a premium industrial flooring solution, engineered for superior load-bearing, anti-slip, and corrosion-resistant performance. It is crafted by mechanically locking cross bars into notched-bearing bars under heavy pressure—a process guaranteeing rigid, durable panels ideal for demanding environments.

View Detailed Specs & PricingManufacturing Process Flow: Swage-Locked Metal Grating For Sale

Technical Parameters of Metal Grating For Sale

| Parameter | Swage-Locked Grating | Welded Grating | Press-Locked Grating |

|---|---|---|---|

| Material Types | Carbon Steel, Stainless Steel, Aluminum | Carbon Steel, Stainless Steel | Carbon Steel, Aluminum |

| Production Method | Hydraulic Swaging, CNC Cutting | Resistance Welding | Mechanical Press-locking |

| Surface Treatment | Hot Dip Galvanizing, Powder Coating | Galvanizing, Painting | Galvanizing, Painting |

| Serration for Anti-slip | Available | Available | Optional |

| Corrosion Resistance | Excellent (ISO 12944-6) | Good | Medium |

| Standard Size (mm) | 1000x6000, Custom | 1000x6000, Custom | 1000x4000, Custom |

| Span-to-Depth Ratio | Up to 40:1 | Up to 30:1 | Up to 25:1 |

| Weight per m² (kg) | 21–60 | 22–68 | 18–45 |

| Service Life | >30 years | 20–30 years | 15–25 years |

Key Advantages of Swage-Locked Steel Grating

- High Strength-to-Weight Ratio: Swage-locked design delivers superior stiffness with less weight, ideal for high-load industrial walkways.

- Corrosion Resistance: Hot dip galvanization in accordance with ISO 1461 provides >20 years outdoor service life, protecting metal grating for sale even in marine and chemical environments.

- Slip Resistance: Serrated surfaces exceed OSHA and EN 13501 anti-slip criteria; optimal for wet/oily production areas.

- Custom Manufacturing: Panel size, bar thickness, serration & finish tailored to project needs (buy steel grating in almost any shape/spec).

- Low Maintenance: Integrated design requires no periodic tightening or reconnection, reducing TCO (Total Cost of Ownership).

- International Certification: ISO9001, ANSI/NAAMM, and CE-compliance as per customer/region requirements.

Industry Application Scenarios

- Petrochemical Plants: Floor walkways, pipe racks, access stairs—excellent resistance to corrosive chemicals and high loads.

- Water Treatment & Drainage: Grating as covers for channels and secondary containment—certified anti-slip and hydrophobic surfaces.

- Metallurgy & Mining: Heavy-duty flooring in smelting/refining facilities; withstands high-temperature environments.

- Power Stations & Energy: Walkways and service platforms on turbines, boilers, and transformers.

- Marine/Shipbuilding: Saltwater-resistant deck grating certified for DNV/ABS standards.

Swage-Locked Grating installed across 14,000 sqm pipe rack accessways for Sinopec. After 12 months:

- Zero corrosion observed under heavy chemical vapor flow

- Maintenance inspections reduced to once annually

- Operator injury rates for slips and falls cut by 61% (compared to non-serrated platforms)

Comparison of Leading Metal Grating Manufacturers

| Brand/Company | Main Type | Certs | Annual Output (m²) | Key Markets | Lead Time (days) |

|---|---|---|---|---|---|

| HF PetroMesh | Swage-Locked | ISO9001, ANSI, CE | 180,000 | Global | 14–25 |

| AMICO | Welded, Press-Locked | ISO, ASTM | 220,000 | USA, CA, EU | 21–35 |

| Webforge | Press-Locked, Welded | ISO, EN | 300,000 | APAC, EU | 18–30 |

| Baosteel | Custom Gratings | ISO, ANSI | 160,000 | China, SE Asia | 20–32 |

Customization & Engineering Consultation

All metal grating for sale products from HF PetroMesh offer:

- CAD Drawing Support: Submit project layouts; engineers review load, deflection, and safety factors for optimal specification.

- Panel Customization: Exact cut-outs, notches, and edge banding for integration with onsite equipment and fixtures.

- Surface Finishing: Choose hot-dip galvanizing, powder coating, or specialized paints (per ISO 12944 corrosion classes).

- Fast-Track Delivery: Standard custom panels ready in 14-25 days, even for large volume orders.

- Turnkey Project Support: Assistance from initial design to final installation guidance.

Customer Experience & Feedback

“Switching to swage-locked metal grating for sale allowed us to cut maintenance costs by 30%, while the galvanizing finish exceeded our expectations for corrosion resistance.” – Facility Manager, 2023

“Serrated carbon steel grating from HF PetroMesh performed flawlessly with zero worker slip injuries in the past year; fabrication and delivery were on schedule.” – Project Engineer, POSCO

FAQ: Technical Terms & Expert Answers

1. What types of steel can be used in metal grating for sale?

2. What is the difference between swage-locked and welded steel grating?

3. Which standards govern the production and installation of steel grating?

4. How is slip-resistance achieved and measured?

5. What is the typical service life of hot-dip galvanized carbon steel grating?

6. What are standard grating panel sizes and thicknesses?

7. How do I select the right types of steel grating for my application?

Supply Cycle, Warranty, and Customer Support

- Lead Time: Standard panels—ready to ship in 7–14 days; customized solutions within 14–25 days.

- Warranty: 10 years for material and workmanship defects. Extended warranty available for special projects.

- Quality Assurance: Each batch is cross-checked against NAAMM MBG531 and ISO9001 requirements.

- Technical Support: Engineering support available from consultation to post-installation; rapid response within 24 hours.

- Global Delivery: Projects shipped worldwide, with packaging designed to minimize onsite work.

- Documentation: Full mill certificates, testing reports, and 3rd party inspections available on request.

Conclusion & Industry References

References & Further Reading:

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025