- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Ots . 18, 2025 10:43

Back to list

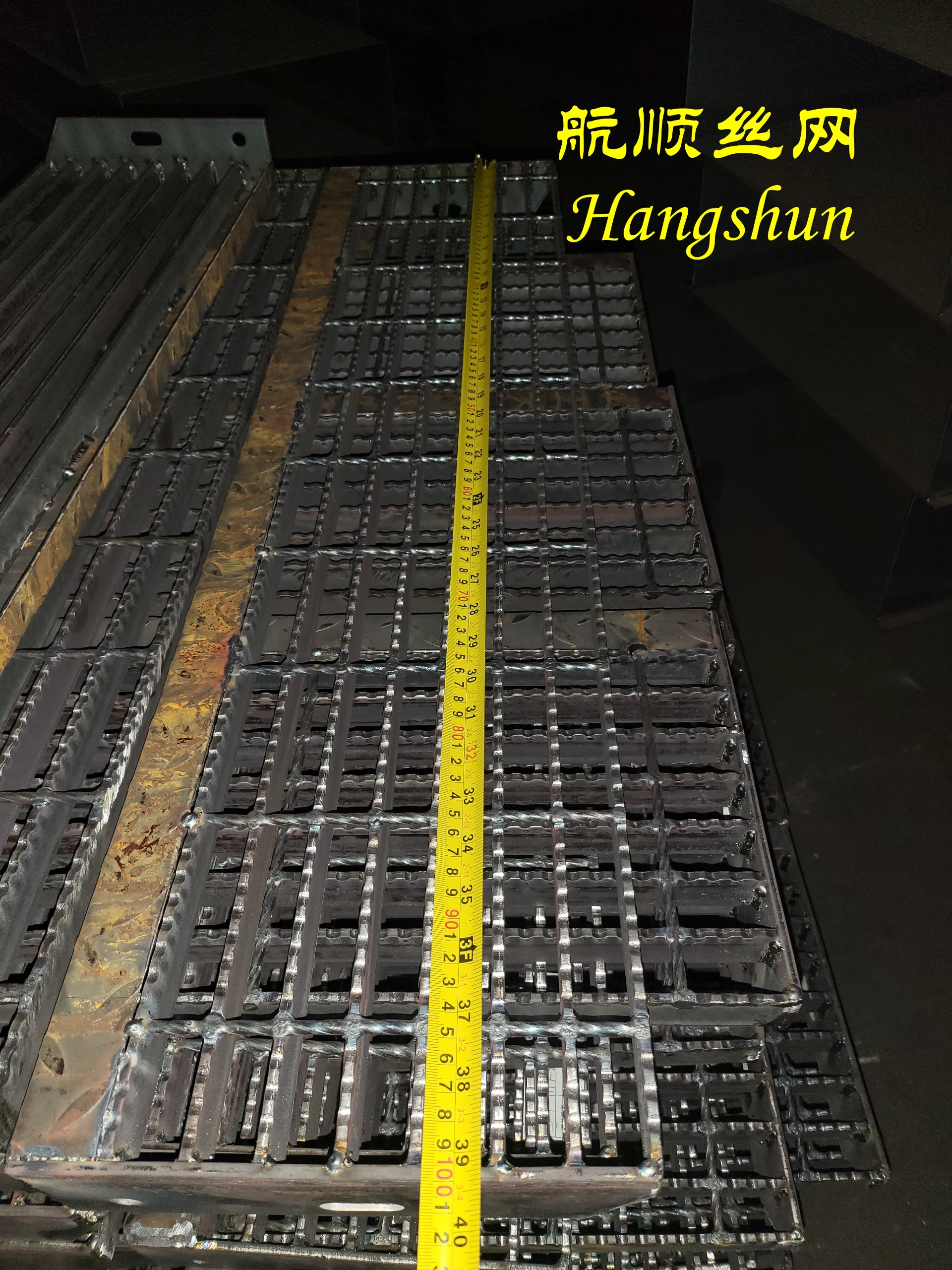

Riveted Grating

Navigating the landscape of galvanized steel grating prices involves understanding a complex interplay of factors that can significantly influence purchasing decisions. Galvanized steel grating, a popular material for a wide range of industrial and commercial applications, is valued for its durability, strength, and resistance to corrosion. However, grasping the nuances of its pricing requires insight into market dynamics, production processes, and quality considerations.

Economic conditions and currency exchange rates further contribute to pricing dynamics. For international buyers, fluctuations in exchange rates could lead to unforeseen costs. It's beneficial to consider contracting in stable currencies or using hedging strategies to manage this risk. Buyers should also be aware of additional services that may impact pricing. Custom fabrication, cutting, or surface treatments such as powder coating can enhance product performance but at added cost. Evaluating whether such services deliver value for the specific needs of a project is essential in determining whether the additional expense is justified. Supply chain relationships are another understated factor. Developing strong relationships with suppliers can lead to beneficial pricing, as long-term commitments often open up opportunities for discounts. Buyers willing to establish these connections may find more favorable terms than those engaging in one-off transactions. Technological advancements in the production of galvanized steel grating have also started to influence costs. As the industry adopts more efficient and sustainable production methods, the initial developmental costs may reflect on prices. However, over time, these technologies can lead to cost reductions and enhanced product capabilities, creating a competitive edge for both producers and consumers who prioritize innovation and sustainability. Finally, the reputation and reliability of suppliers cannot be overstated. In a market where price should reflect value, selecting reputable suppliers who consistently deliver high-quality products ensures return on investment. Reviews, testimonials, and case studies should be part of the decision-making process, allowing buyers to gauge the performance of previous projects and the satisfaction of past clients. In summary, the pricing of galvanized steel grating is influenced by a multitude of factors, each interlinked with the other, creating a dynamic marketplace that demands careful navigation. From raw material costs and galvanization standards to economic conditions and supplier relationships, understanding these elements is key to making informed purchasing decisions that align with budgetary constraints and project goals.

Economic conditions and currency exchange rates further contribute to pricing dynamics. For international buyers, fluctuations in exchange rates could lead to unforeseen costs. It's beneficial to consider contracting in stable currencies or using hedging strategies to manage this risk. Buyers should also be aware of additional services that may impact pricing. Custom fabrication, cutting, or surface treatments such as powder coating can enhance product performance but at added cost. Evaluating whether such services deliver value for the specific needs of a project is essential in determining whether the additional expense is justified. Supply chain relationships are another understated factor. Developing strong relationships with suppliers can lead to beneficial pricing, as long-term commitments often open up opportunities for discounts. Buyers willing to establish these connections may find more favorable terms than those engaging in one-off transactions. Technological advancements in the production of galvanized steel grating have also started to influence costs. As the industry adopts more efficient and sustainable production methods, the initial developmental costs may reflect on prices. However, over time, these technologies can lead to cost reductions and enhanced product capabilities, creating a competitive edge for both producers and consumers who prioritize innovation and sustainability. Finally, the reputation and reliability of suppliers cannot be overstated. In a market where price should reflect value, selecting reputable suppliers who consistently deliver high-quality products ensures return on investment. Reviews, testimonials, and case studies should be part of the decision-making process, allowing buyers to gauge the performance of previous projects and the satisfaction of past clients. In summary, the pricing of galvanized steel grating is influenced by a multitude of factors, each interlinked with the other, creating a dynamic marketplace that demands careful navigation. From raw material costs and galvanization standards to economic conditions and supplier relationships, understanding these elements is key to making informed purchasing decisions that align with budgetary constraints and project goals.

Share

Prev:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025