- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

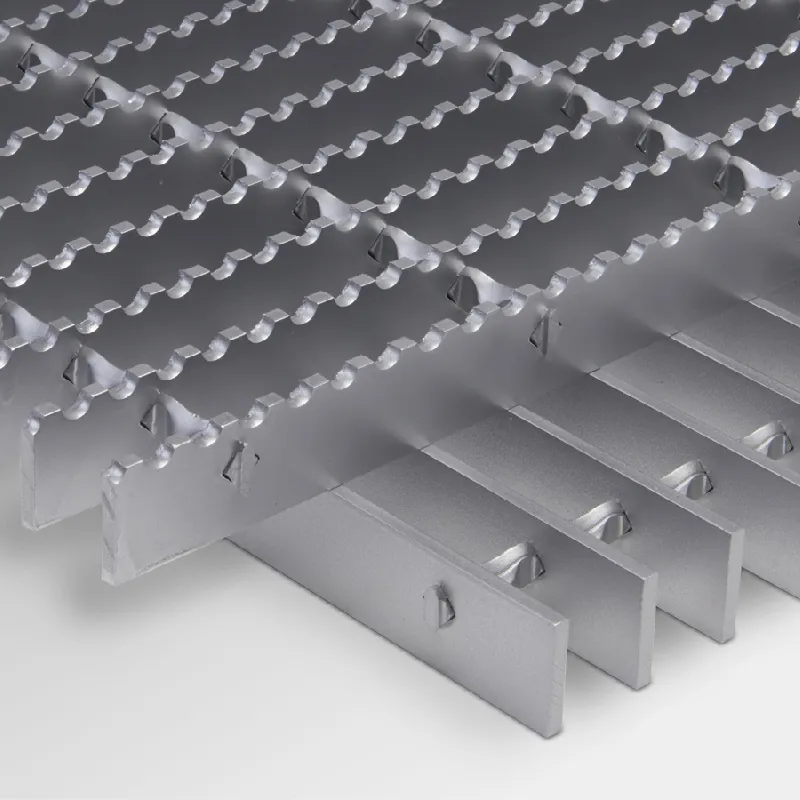

steel grating platform

Steel Grating Platforms A Comprehensive Overview

Steel grating platforms are essential components in various industrial applications, providing safety, durability, and efficiency. These platforms are typically made from steel bars that are welded or mechanically fastened together, creating a grid-like structure. The design of steel grating platforms allows for high load capacity, excellent drainage, and ventilation, making them ideal for environments where both safety and functionality are crucial.

Types of Steel Grating

There are several types of steel grating, each suited for different applications. Some of the most common types include

1. Flat Bar Grating This type features flat bars that are spaced apart, with load bars perpendicular to the span. Flat bar grating is often used in pedestrian walkways and light-duty applications where stability is essential.

2. Heavy-Duty Grating Designed for industrial applications, heavy-duty grating can support heavier loads and is typically used in warehouses, manufacturing plants, and vehicle traffic areas.

3. Open Grating Open grating has wider openings between the bars, allowing for better drainage and airflow. It is commonly used in environments where spills or debris management is necessary, such as in chemical plants or outdoor settings.

4. Treaded Grating This specialized grating features a non-slip surface, making it ideal for walkways and platforms where safety is a concern. Treaded grating is commonly used in areas that experience high foot traffic or are prone to water accumulation.

Key Benefits

The benefits of using steel grating platforms are numerous. Some of the most notable advantages include

- Strength and Durability Steel grating platforms are incredibly strong, capable of withstanding heavy loads and harsh environmental conditions. This makes them suitable for use in various industries, including oil and gas, construction, and manufacturing.

steel grating platform

- Safety With anti-slip surfaces and a stable design, steel grating platforms significantly reduce the risk of slips and falls, enhancing workplace safety

.- Versatility Steel grating platforms can be customized to meet specific dimensional requirements, making them adaptable for various uses—ranging from elevated walkways to support structures for machinery.

- Cost-Effectiveness While the initial investment for steel grating platforms may be higher than other materials, their longevity and minimal maintenance requirements often make them more cost-effective in the long run.

- Environmental Resistance Steel grating platforms can be treated with coatings to resist corrosion and other environmental damage, further extending their lifespan.

Installation and Maintenance

Installing steel grating platforms typically involves direct bolting or welding to support structures. The process can be complex and may require skilled labor, especially in heavy-duty applications. Proper care must be taken to ensure that the grating is securely fastened and that any potential hazards are addressed during installation.

Maintenance of steel grating platforms is relatively straightforward. Regular inspections for rust or physical damage should be conducted, and any debris that accumulates should be cleared to maintain drainage and safety. Depending on the environmental conditions, periodic repainting or re-coating may be necessary to protect against corrosion.

Applications

Steel grating platforms find applications across a multitude of sectors. In the oil and gas industry, they are used for walkways, support structures, and safety barriers. In manufacturing, they provide robust flooring options for machinery and assembly lines. Moreover, they are common in wastewater treatment plants, power generation facilities, and various outdoor settings, ensuring functionality and safety in diverse operational environments.

Conclusion

In summary, steel grating platforms represent a fundamental element in modern industrial infrastructure. Their combination of strength, safety, versatility, and cost-effectiveness makes them an ideal choice for a variety of applications. As industries continue to evolve, the demand for reliable and durable solutions like steel grating platforms will only increase, ensuring their place in future developments across numerous sectors. Whether for new construction or upgrades to existing facilities, investing in high-quality steel grating platforms is a decision that pays dividends in safety, performance, and longevity.

-

Welded Steel Bar Grating: The Strongest Choice for Industrial FlooringNewsMay.21,2025

-

Steel Grating for Sale: The Ultimate Anti-Slip SolutionNewsMay.21,2025

-

Steel Frame Shaker Screens: Unmatched Durability for Demanding OperationsNewsMay.21,2025

-

Shaker Screens: Your Ultimate Solution for Oil & Gas FiltrationNewsMay.21,2025

-

Press Locked Steel Grating: The Smarter Choice for Heavy-Duty FlooringNewsMay.21,2025

-

Helicopter Deck Safety Nets: Protect Your Crew and EquipmentNewsMay.21,2025