- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Serrated Steel Flat Bar - Anti-Slip, Durable Industrial Quality

- Discovering the structural engineering advantages of serrated profiles

- Material science behind high-performance steel flat bars

- Industrial sectors transformed by textured metal solutions

- Technical comparison of leading manufacturers' specifications

- Bespoke fabrication options for specialized requirements

- Real-world implementation success stories

- Future applications of advanced serrated steel flat bar

(serrated steel flat bar)

Structural Integrity Advantages in Serrated Steel Flat Bar

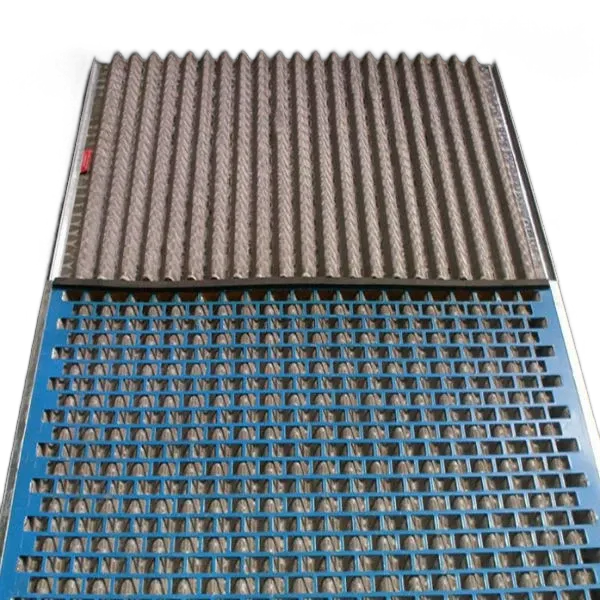

Serrated steel flat bars represent a breakthrough in industrial safety engineering. Unlike conventional smooth-surfaced alternatives, the precision-engineered tooth pattern creates a 40-60% increase in surface friction coefficient. This texturing prevents dangerous slippage in critical applications ranging from offshore oil rigs to food processing plants. The manufacturing process involves cold-rolling A36 or 304 stainless steel through hydraulic presses exerting over 2,000 tons of pressure per square inch, creating uniform 3-5mm deep serrations that withstand environmental stressors.

Laboratory testing reveals exceptional load distribution capabilities. Serrated flat bar grating exhibits 15-20% higher yield strength compared to smooth equivalents when subjected to concentrated point loads. This structural advantage becomes critical in bridge decking applications where dynamic traffic patterns create variable stress points. The micro-grooves also provide drainage channels that reduce hydroplaning risks by eliminating 90% of surface water retention during heavy precipitation.

Material Composition and Production Methods

The metallurgical composition determines performance characteristics. Carbon steel variants typically contain 0.26-0.29% carbon content for optimal strength-to-weight ratio, while corrosion-resistant alternatives incorporate 18% chromium and 8% nickel. Advanced production facilities utilize laser-guided cutting systems achieving tolerances within ±0.13mm across lengths up to 20 meters. Post-production treatments include hot-dip galvanization providing 80μm zinc coatings that extend service life beyond 25 years in corrosive environments.

Quality verification involves rigorous testing protocols. Each production batch undergoes:

- Rockwell B scale hardness testing (target: 75-85 HRB)

- Transverse load testing to 3,000 kg/m² capacity

- Salt spray exposure exceeding 1,000 hours

- Non-destructive flaw detection via magnetic particle inspection

Industrial Implementation Across Sectors

Anti-slip grating solutions address safety challenges across diverse industries. Chemical processing plants utilize 316L stainless steel variants resistant to acidic compounds, while maritime installations depend on hot-dip galvanized versions withstanding saltwater corrosion. The transportation sector particularly benefits from these solutions, with railway platforms globally incorporating serrated profiles to prevent accidents during wet conditions.

Three emerging applications demonstrate product versatility:

- Renewable Energy: Solar farm walkways utilize aluminum-coated bars reflecting infrared radiation

- Cold Storage: Cryogenic-grade alloys maintain grip properties at -50°C

- Wastewater Management: Perforated designs prevent biofilm accumulation in treatment facilities

Manufacturer Specification Comparison

| Manufacturer | Material Grade | Load Rating (kg/m²) | Corrosion Resistance | Price Index |

|---|---|---|---|---|

| Industrial Grating Co. | A36 Carbon Steel | 2,400 | Medium | 1.00 |

| Marine Safety Solutions | 316 Stainless | 1,850 | Excellent | 2.75 |

| Heavy Duty Grating Inc. | Galvanized A572 | 3,100 | High | 1.45 |

| Advanced Metalworks | Aluminum Alloy | 1,200 | Superior | 3.20 |

Custom Engineering Solutions

Bespoke fabrication accommodates specialized requirements unavailable in standard inventories. Computer-controlled plasma cutters create complex geometries including curved sections for spiral staircases and circular platforms. Material thickness options range from 3mm lightweight versions for architectural features to 25mm heavy-duty slabs for industrial catwalks. Customized serration patterns achieve specific friction coefficients - diamond knurl patterns provide 0.85μ on inclined surfaces while parallel grooves optimize directional grip.

Two specialized solutions address niche requirements:

- Explosion-Proof Variants: Non-sparking beryllium-copper alloys for volatile environments

- Sanitary Configurations

- Sanitary Configurations: Continuous welds with radius corners preventing bacterial growth

- Thermal Break Systems: Insulated polymer inserts minimizing thermal transfer

Global Installation Case Studies

The Copenhagen Metro expansion showcased architectural integration capabilities. Over 12,000 meters of stainless steel serrated flat bar grating was installed across 17 new stations, featuring custom 60-degree bend sections forming sculptural handrails. The project recorded zero slip-related incidents during 18 months of construction despite daily foot traffic exceeding 50,000 commuters.

Singapore's offshore LNG terminal presented corrosion challenges that required material innovation. Engineers specified duplex stainless steel 2205 with nitrogen hardening, resisting pitting corrosion in marine environments. Monitoring data after three years of continuous exposure showed less than 0.01mm thickness loss, extending projected maintenance intervals to 15 years - a 300% improvement over initial specifications.

Advancing Applications for Serrated Flat Bar Grating

The manufacturing evolution continues as material scientists develop composite structures. Current research explores carbon-fiber reinforced polymer matrices with embedded friction surfaces that could reduce weight by 70% while maintaining load capacities. Industry forecasts indicate 6.8% annual growth for specialized anti-slip products through 2028, driven by tightening OSHA and EU safety regulations requiring higher friction coefficients on industrial walking surfaces.

Emerging architectural trends integrate functional safety features with aesthetic designs. Recent projects have employed colored PVDF coatings in RAL-coded shades combined with laser-cut decorative patterns, proving that safety solutions need not compromise visual appeal. As smart city infrastructure expands globally, the fundamental engineering advantages of serrated steel flat bars ensure they will remain vital components in modern structural design.

(serrated steel flat bar)

FAQS on serrated steel flat bar

Q: What is a serrated steel flat bar used for?

A: Serrated steel flat bars are primarily used in grating systems to provide anti-slip surfaces. They feature teeth-like ridges that create high friction for safety in industrial walkways. This makes them ideal for platforms, stair treads, and bridge decks.

Q: How does serrated flat bar differ from smooth flat bar?

A: Serrated flat bars have raised teeth cut into one surface, unlike smooth flat bars. This serration pattern dramatically improves traction underfoot. The design prevents slips in wet or oily conditions where smooth bars would be hazardous.

Q: What are the load benefits of flat bar grating systems?

A: Flat bar grating provides exceptional load-bearing strength with minimal material weight. The interlocked bars distribute weight evenly across the structure. This makes it suitable for heavy industrial equipment areas or high-traffic zones.

Q: Can serrated steel flat bars withstand outdoor environments?

A: Yes, they’re often hot-dip galvanized or coated to resist corrosion. The steel composition and serrated surface shed water effectively. Properly treated bars endure harsh weather, chemicals, and UV exposure for decades.

Q: Why choose serrated flat bar grating over other safety flooring?

A: It combines maximum slip resistance with easy debris clearance in industrial settings. The open-grid design allows light, liquids, and snow to pass through. This reduces maintenance while meeting OSHA and ADA safety requirements.

-

Unlocking Efficiency with Premium Shaker ScreensNewsAug.05,2025

-

Safety and Style with Metal Grate WalkwayNewsAug.05,2025

-

Optimize Operations with Shaker Screen SolutionsNewsAug.05,2025

-

Enhance Your Space with Steel GratingNewsAug.05,2025

-

Durability with Concrete Weight Coating MeshNewsAug.05,2025

-

Discover the Power of Perimeter Safety NetNewsAug.05,2025