- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

jaan. . 16, 2025 05:36

Back to list

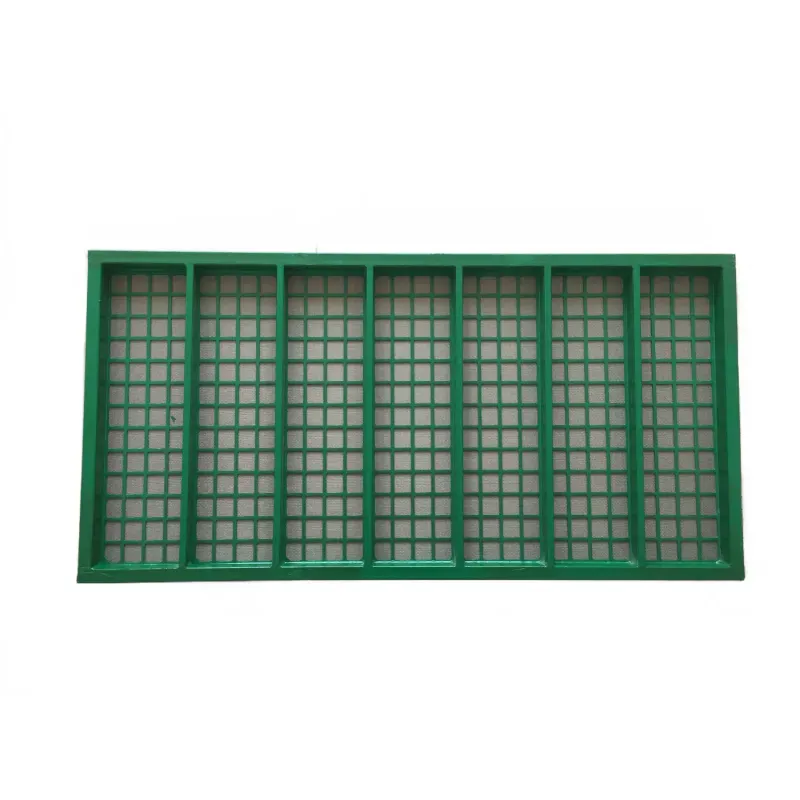

Riveted Grating

Industrial floor grating has become an essential component in modern infrastructure, particularly in industrial settings where durability, safety, and efficiency are paramount. As a long-time expert in this field, I've amassed a wealth of experience working with industrial floor grating solutions across various sectors, enabling businesses to streamline operations while maintaining the highest safety standards.

A pivotal consideration when selecting floor grating is safety, a factor I deem non-negotiable. Industrial settings often encounter slippery surfaces due to oil, water, or other liquids, making slip resistance a critical aspect of floor grating design. Gratings with serrated surfaces have proven to significantly enhance grip and floor safety. Additionally, ensuring that gratings meet national and international safety standards is crucial to maintaining workplace safety and compliance. In my experience, customization in industrial floor grating can greatly amplify its efficacy. Tailoring grating dimensions to match specific floor layouts and incorporating additional features such as edge nosing or contrasting colors can improve both functionality and safety. This customization is not just about fitting the physical space but also about meeting operational protocols and enhancing workflow efficiency. Maintaining the integrity of industrial floor grating is another area where expertise plays a vital role. Regular inspection and maintenance routines ensure that gratings remain safe and functional over time. I advocate for a proactive approach, involving periodic checks for signs of wear and tear, rust in metallic gratings, or cracks in fiberglass options. Timely intervention can prevent minor issues from escalating into costly repairs or replacements, safeguarding the enterprise's investment. As a trusted authority in industrial floor grating, my approach is grounded in understanding specific industrial challenges and aligning the right grating solutions to meet those challenges. The evolving nature of industrial operations demands grating solutions that can keep pace, adapt, and provide sustainable value. Through a combination of expert knowledge, experience, and a commitment to quality and safety, I strive to ensure that each grating installation not only meets but exceeds industry standards and client expectations.

A pivotal consideration when selecting floor grating is safety, a factor I deem non-negotiable. Industrial settings often encounter slippery surfaces due to oil, water, or other liquids, making slip resistance a critical aspect of floor grating design. Gratings with serrated surfaces have proven to significantly enhance grip and floor safety. Additionally, ensuring that gratings meet national and international safety standards is crucial to maintaining workplace safety and compliance. In my experience, customization in industrial floor grating can greatly amplify its efficacy. Tailoring grating dimensions to match specific floor layouts and incorporating additional features such as edge nosing or contrasting colors can improve both functionality and safety. This customization is not just about fitting the physical space but also about meeting operational protocols and enhancing workflow efficiency. Maintaining the integrity of industrial floor grating is another area where expertise plays a vital role. Regular inspection and maintenance routines ensure that gratings remain safe and functional over time. I advocate for a proactive approach, involving periodic checks for signs of wear and tear, rust in metallic gratings, or cracks in fiberglass options. Timely intervention can prevent minor issues from escalating into costly repairs or replacements, safeguarding the enterprise's investment. As a trusted authority in industrial floor grating, my approach is grounded in understanding specific industrial challenges and aligning the right grating solutions to meet those challenges. The evolving nature of industrial operations demands grating solutions that can keep pace, adapt, and provide sustainable value. Through a combination of expert knowledge, experience, and a commitment to quality and safety, I strive to ensure that each grating installation not only meets but exceeds industry standards and client expectations.

Share

Prev:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025