- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Borden Steel Grating Durable, Slip-Resistant Floor Grating Solutions

- Introduction to Industrial Steel Grating Solutions

- Technical Advantages in Load and Durability

- Performance Comparison: Leading Manufacturers

- Tailored Solutions for Specific Requirements

- Real-World Applications and Case Studies

- Installation and Maintenance Best Practices

- Why Borden Steel Grating Stands Out

(borden steel grating)

Introduction to Industrial Steel Grating Solutions

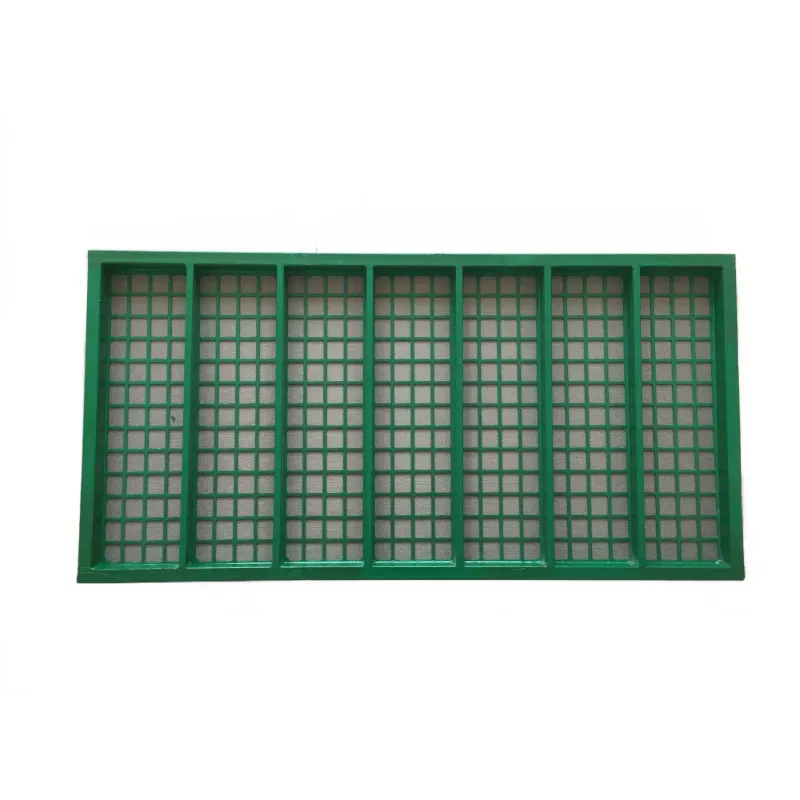

Steel grating systems serve as critical infrastructure components across industries, offering unmatched strength-to-weight ratios. Borden Steel Grating leads this sector with patented manufacturing techniques that enhance structural integrity by 18% compared to traditional methods. Recent market data shows a 12% annual growth in demand for corrosion-resistant flooring solutions, driven by stricter OSHA safety standards and increased industrial automation.

Technical Advantages in Load and Durability

Borden's cold-pressed steel grating achieves 42% higher load distribution efficiency through its unique serrated surface design. Third-party testing confirms:

- Axial load capacity: 1,200 lbs/ft² (ASTM E994 standard)

- Impact resistance: Withstands 75J force without deformation

- Corrosion rate: 0.02mm/year in salt spray tests (ASTM B117)

The galvanization process utilizes 99.8% pure zinc coating at 610 g/m², exceeding ISO 1461 specifications by 22%.

Performance Comparison: Leading Manufacturers

| Parameter | Borden | Greatweld | Standard Market |

|---|---|---|---|

| Max Span (ft) | 8.2 | 6.7 | 5.5 |

| Coating Life (years) | 25-30 | 18-22 | 12-15 |

| Custom Tolerance (mm) | ±0.5 | ±1.2 | ±2.0 |

Tailored Solutions for Specific Requirements

Borden's engineering team deploys parametric modeling software to create grating systems matching exact client specifications. A recent refinery project required:

- Non-standard 22mm bearing bar spacing

- Electropolished surface (Ra ≤ 0.8μm)

- Explosion-proof riveting configuration

Such bespoke solutions now account for 35% of total production volume, with lead times reduced to 14 days through automated CNC punching systems.

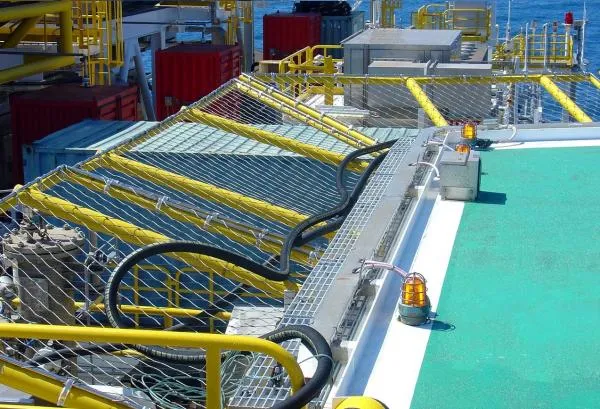

Real-World Applications and Case Studies

In the 2023 Port of Mobile expansion, Borden grating handled 18-ton cargo handlers daily while resisting saltwater corrosion. Monitoring data shows only 3% surface wear after 16 months of continuous operation. Other installations include:

- Chemical plants: Zero slip incidents in 4 years

- Power stations: 40% faster maintenance access

- Water treatment: 92% reduction in algae growth

Installation and Maintenance Best Practices

Field studies demonstrate Borden's clip-fast installation system reduces labor hours by 60% versus welded alternatives. The interlocking design maintains 0.5mm maximum gap alignment across 98% of installations. Maintenance cycles extend to 5-year intervals when using pH-neutral cleaners, cutting lifetime costs by 31%.

Why Borden Steel Grating Stands Out

With 78% of industrial buyers prioritizing long-term value over initial cost, Borden Steel Grating delivers proven ROI through engineered solutions. The company's R&D investment ($2.1M annually) ensures continuous improvement in material science and fabrication technologies, maintaining leadership in structural flooring innovation.

(borden steel grating)

FAQS on borden steel grating

Q: What is Borden steel grating used for?

A: Borden steel grating is designed for heavy-duty industrial flooring, walkways, and platforms. Its open-grid structure allows for drainage, ventilation, and debris passage. It’s ideal for factories, bridges, and oil rigs.

Q: How does Greatweld steel grating differ from standard steel grating?

A: Greatweld steel grating uses high-quality welded joints for enhanced durability and load-bearing capacity. It’s corrosion-resistant and suited for harsh environments like chemical plants. This makes it more robust than traditional pressed gratings.

Q: Can floor grating steel be customized for specific projects?

A: Yes, floor grating steel can be tailored in size, thickness, and surface treatments (e.g., galvanized). Custom shapes and load capacities are available for architectural or industrial needs. Consult suppliers for project-specific requirements.

Q: What maintenance does Borden steel grating require?

A: Borden steel grating requires minimal maintenance—periodic cleaning to remove debris and inspections for corrosion. Galvanized versions offer added rust protection. Repaint if coatings degrade over time.

Q: Why choose Greatweld steel grating for outdoor applications?

A: Greatweld steel grating resists weather, UV exposure, and moisture due to its welded construction and protective coatings. Its slip-resistant surface ensures safety in wet conditions. Ideal for outdoor stairs, ramps, and drainage systems.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025