- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Feb . 10, 2025 11:28

Back to list

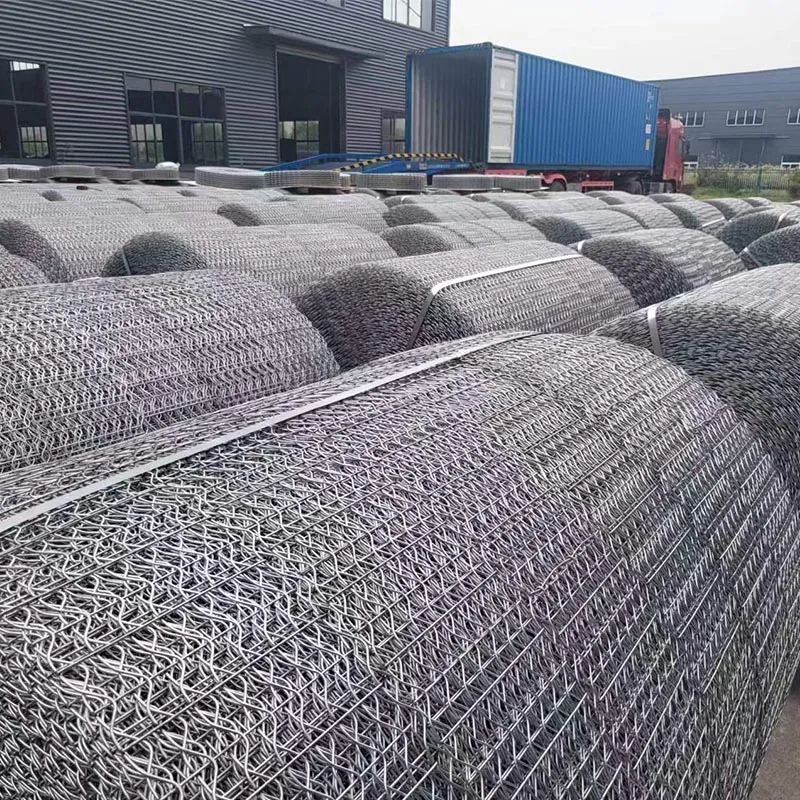

shale shaker screen

In the ever-evolving realm of the oil and gas industry, the shale shaker screen emerges as an indispensable component, widely revered for its ability to separate solids from drilling fluids—a critical operation in the quest for oil extraction efficiency. To fully appreciate the significance of shale shaker screens, one must delve into their intricacies, appreciate the technological advances that have propelled their development, and understand how they integrate into the broader drilling system.

The authority of a manufacturer in the παραγωγή οθονών αναδευτήρα σχιστόλιθου συνίσταται στην ικανότητά του να παρέχει προϊόντα που όχι μόνο καλύπτουν τις προδιαγραφές του κλάδου αλλά υπερβαίνουν τις προσδοκίες απόδοσης. Leading manufacturers invest heavily in research, optimizing wire configurations and developing proprietary materials engineered to achieve precise filtration at high efficiencies. Such authoritative manufacturers not only supply high-quality screens but also offer invaluable support and training to drilling operators, ensuring implementation aligns with technical specifications. Trustworthiness within the industry is established through a track record of delivering consistently reliable products backed by comprehensive customer service. For instance, a trustworthy shale shaker screen supplier provides more than just a transaction; it involves forming a partnership with their clients. Providing detailed user manuals, holding training sessions, offering maintenance tips, and having responsive customer service teams are just a few of how reputable companies establish trust. Moreover, legitimate suppliers are transparent about their products' capabilities and limitations, ensuring that operators are well-informed about what they can expect in terms of performance and longevity. Providing upfront, honest information is a cornerstone in fostering trust and building long-term relationships in the industry. At the intersection of experience, expertise, authoritativeness, and trustworthiness lies the key to capitalizing on the shale shaker screen's full potential. The ability to effectively separate solids and maintain the cleanliness of drilling fluids can have profound effects on the efficiency and cost-effectiveness of drilling operations. As drilling technologies continue to advance, the shale shaker screen remains a fundamental element of the drilling rig, its ongoing evolution testimony to the relentless pursuit of efficiency in oil extraction.

The authority of a manufacturer in the παραγωγή οθονών αναδευτήρα σχιστόλιθου συνίσταται στην ικανότητά του να παρέχει προϊόντα που όχι μόνο καλύπτουν τις προδιαγραφές του κλάδου αλλά υπερβαίνουν τις προσδοκίες απόδοσης. Leading manufacturers invest heavily in research, optimizing wire configurations and developing proprietary materials engineered to achieve precise filtration at high efficiencies. Such authoritative manufacturers not only supply high-quality screens but also offer invaluable support and training to drilling operators, ensuring implementation aligns with technical specifications. Trustworthiness within the industry is established through a track record of delivering consistently reliable products backed by comprehensive customer service. For instance, a trustworthy shale shaker screen supplier provides more than just a transaction; it involves forming a partnership with their clients. Providing detailed user manuals, holding training sessions, offering maintenance tips, and having responsive customer service teams are just a few of how reputable companies establish trust. Moreover, legitimate suppliers are transparent about their products' capabilities and limitations, ensuring that operators are well-informed about what they can expect in terms of performance and longevity. Providing upfront, honest information is a cornerstone in fostering trust and building long-term relationships in the industry. At the intersection of experience, expertise, authoritativeness, and trustworthiness lies the key to capitalizing on the shale shaker screen's full potential. The ability to effectively separate solids and maintain the cleanliness of drilling fluids can have profound effects on the efficiency and cost-effectiveness of drilling operations. As drilling technologies continue to advance, the shale shaker screen remains a fundamental element of the drilling rig, its ongoing evolution testimony to the relentless pursuit of efficiency in oil extraction.

Share

Prev:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025