- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

galvanized grating cost

Understanding the Cost of Galvanized Grating Key Factors and Considerations

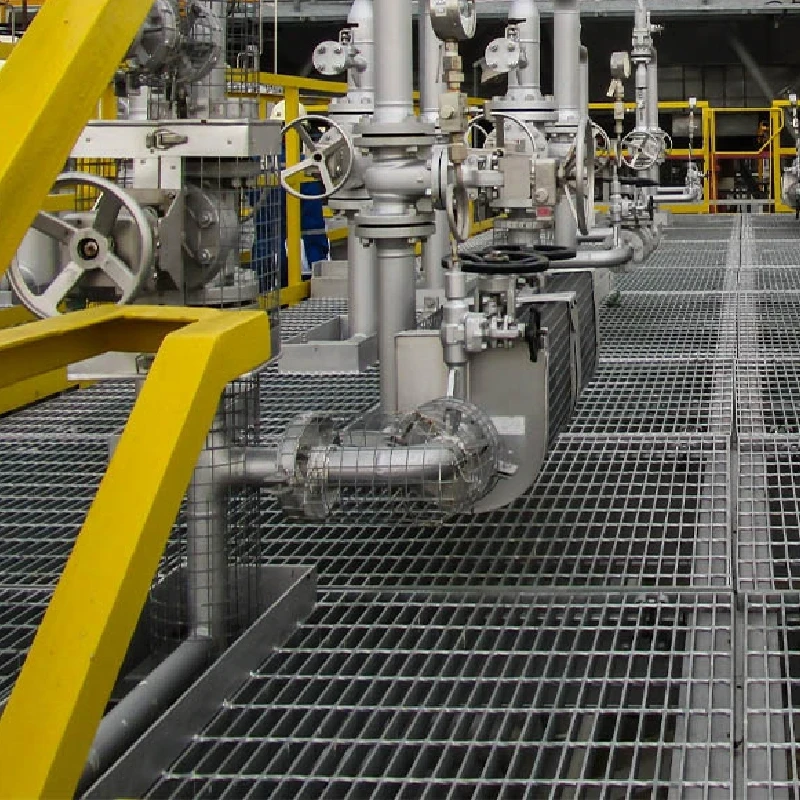

Galvanized grating is a popular choice in various industries due to its durability, corrosion resistance, and strength. It is commonly used in walkways, platforms, and drainage covers, among other applications. However, when considering the installation of galvanized grating, cost becomes a crucial factor. Understanding what influences the cost can help you make informed decisions and budget effectively for your project.

1. Material and Manufacturing Process

The primary component of galvanized grating is steel, which undergoes a galvanization process to enhance its resistance to corrosion. The cost of raw steel fluctuates depending on market conditions, influencing the price of galvanized grating. Additionally, the manufacturing process, which includes cutting, welding, and coating, adds to the overall expense. Some manufacturers use more advanced techniques that may result in higher-quality products, but these may also come at a premium.

There are various types of galvanized grating, such as welded, press-locked, and swage-locked grating. Each type has its distinct benefits and applications, which can affect the cost. For instance, welded grating tends to be more robust and is suitable for heavy loads, but it is often more expensive than other types. Understanding your specific needs will help you determine which type of grating is most cost-effective for your project.

3. Size and Thickness

galvanized grating cost

The dimensions of the grating also play a significant role in determining the cost. Larger panels or those with greater thickness require more material, resulting in higher prices. It's essential to assess the specific requirements of your application in terms of load capacity and size to find the right balance between cost and functionality.

4. Customization and Accessories

If your project demands custom sizes or special features, such as non-slip surfaces or specific coatings, these factors will add to the overall cost. Accessories like brackets, fasteners, and support structures are also important to consider, as they contribute to both the installation and total project expense. Planning for these additional costs is crucial for accurate budgeting.

5. Supplier and Quantity

The choice of supplier can significantly influence the price of galvanized grating. Different suppliers may offer varying prices based on their manufacturing processes, quality controls, and relationships with steel providers. Additionally, purchasing in bulk can lead to discounts, so if your project requires a large volume, it may be economically advantageous to order accordingly.

Conclusion

In summary, the cost of galvanized grating is influenced by several key factors, including material and manufacturing processes, type and size of grating, customization, and supplier selection. By understanding these aspects, project managers and procurement specialists can make well-informed decisions that ensure they obtain high-quality galvanized grating at a reasonable price. Careful planning and consideration will ultimately lead to a successful installation that meets both functional and budgetary requirements.

-

The Versatility of Steel Walkway GratingNewsAug.07,2025

-

The Benefits of Galvanized Steel Grating for Your ProjectsNewsAug.07,2025

-

Shaker Screens: The Ultimate Solution for Your Drilling NeedsNewsAug.07,2025

-

Perimeter Safety Net: An Essential Solution for Helipad SafetyNewsAug.07,2025

-

Enhance Safety and Efficiency with Steel Walkway GratingNewsAug.07,2025

-

Discover Exceptional Steel Grating for SaleNewsAug.07,2025