- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

aluminum grating price

Understanding Aluminum Grating Prices Factors and Insights

Aluminum grating has become an increasingly popular choice in various industries for its lightweight, corrosion-resistant, and durable properties. Whether used in industrial flooring, walkways, or drainage solutions, the demand for aluminum grating has led to an interest in understanding its pricing structure. This article delves into the factors influencing aluminum grating prices and provides insights that can aid in making informed purchasing decisions.

1. Material Quality

The quality of aluminum used in the production of grating plays a pivotal role in determining the price. High-grade aluminum alloys, such as 6061 and 6063, are generally more expensive due to their superior strength and corrosion resistance. These alloys are designed for structural applications, providing strength and durability over time. Conversely, lower-grade aluminum may come at a cheaper price but can result in reduced lifespan and performance, leading to higher maintenance costs in the long run.

2. Manufacturing Processes

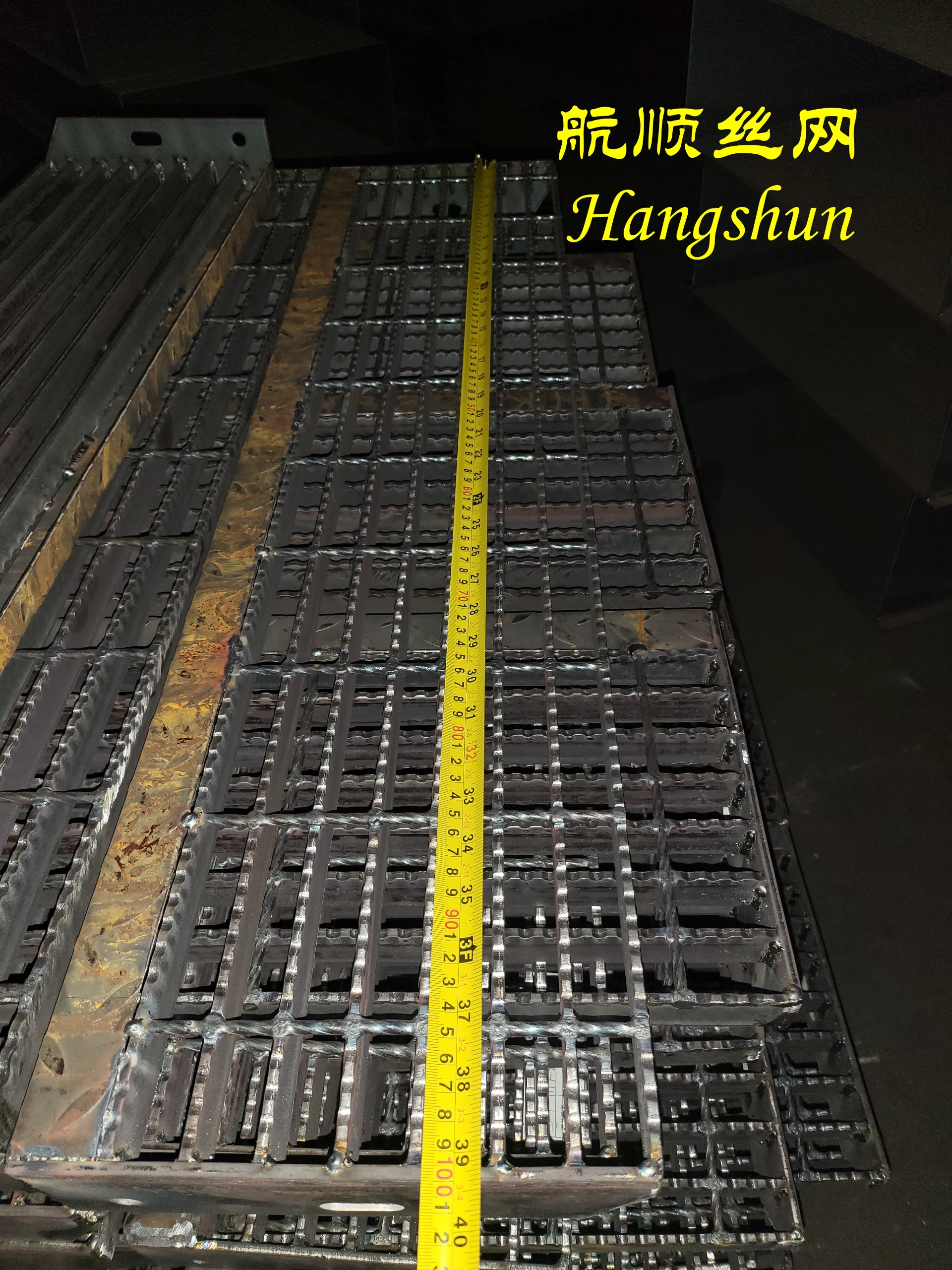

The method used to manufacture aluminum grating also affects its cost. Common manufacturing processes include extruding, casting, and pressing. Extruded aluminum grating, which is produced by forcing aluminum through a die to create a specific shape, is often more expensive due to the advanced technology and equipment involved. On the other hand, pressed or welded gratings may be less costly, but they may not always meet the same quality standards as extruded products. Investors should weigh the benefits of these manufacturing methods against their budget and long-term needs.

Custom designs and specific dimensions can significantly impact the price of aluminum grating. Standard sizes and shapes are typically more affordable and readily available, while custom orders may incur additional charges due to special tooling and production requirements. Buyers should consider whether standard options meet their needs or if custom solutions are necessary for their specific applications.

4. Load Capacity and Safety Standards

aluminum grating price

Aluminum grating is designed to handle varying loads depending on its intended use. The load capacity, which is dictated by the thickness and spacing of the grating bars, can influence the price. Gratings designed for heavy-duty applications, such as in industrial settings or heavy pedestrian traffic, will typically cost more than those intended for lighter loads. Additionally, compliance with safety standards and regulations can add to the overall cost, as manufacturers may need to perform additional testing and certification.

5. Surface Finishes

The surface finish of aluminum grating is another aspect that can impact pricing. Common finishes include mill finish, painted, anodized, and powder-coated options. Anodizing and powder coating enhance corrosion resistance and can provide aesthetic appeal but come at an extra cost compared to standard mill finishes. Buyers should assess the importance of surface treatment for their applications and budget accordingly.

6. Market Fluctuations

Additionally, fluctuations in the global aluminum market can influence pricing. Factors such as raw material costs, production capacity, and trade tariffs can lead to variations in aluminum prices. It’s advisable for potential buyers to stay informed about market trends and price movements to make educated purchasing decisions.

7. Supplier Reputation and Services

The reputation of the supplier or manufacturer also plays a role in the pricing of aluminum grating. Well-established companies may charge a premium for their products due to their track record of quality and service. However, newer suppliers might offer competitive pricing to attract customers. It's crucial to evaluate not only the price but also the reliability, customer service, and warranty options provided by the supplier.

Conclusion

When considering aluminum grating for any application, understanding the various factors that influence pricing is essential. From material quality and manufacturing processes to specific design requirements and market conditions, a comprehensive assessment will lead to more informed purchasing decisions. Investing time in researching and comparing different suppliers can yield significant long-term benefits, ensuring that the chosen aluminum grating meets both performance and budgetary expectations. In a world where durability and safety are paramount, making the right choice in aluminum grating can ultimately contribute to the success and efficiency of any project.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025