- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

jan . 20, 2025 05:26

Back to list

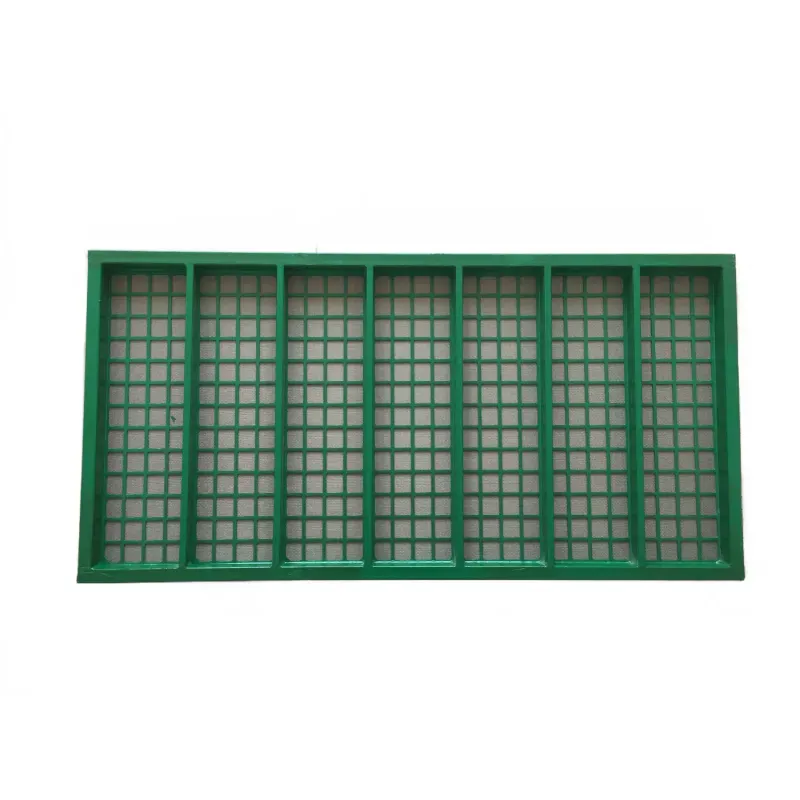

stainless steel grating specification

Navigating the world of steel gratings is crucial for industries requiring reliable infrastructure solutions. Stainless steel grating is an essential component in sectors ranging from construction to food processing, valued for its durability, versatility, and aesthetic appeal. This piece offers an in-depth overview of stainless steel grating specifications to help businesses make informed decisions.

The finish of the stainless steel grating also plays a vital role. Options include mill, electropolished, and powder-coated finishes, each serving distinct purposes. Mill finish is raw and subtly polished, presenting a cost-effective solution. Electropolishing enhances corrosion resistance and hygiene, perfect for the food and beverage industry by delivering a smoother surface less prone to microbial accumulation. Powder-coating offers additional protection and customizable aesthetics, particularly where color coding or branding is crucial. Fabrication techniques such as welding and swaging influence the grating's strength and performance. Welded bar grating offers robustness through fusion welding—a process integrating all contact points. This method is favored in heavy-load environments, including industrial floors and vehicle access roads. Swage-locked and press-locked grating offer alternative fabrications, with swage-lock providing a tighter connection beneficial for aesthetic constructions, and press-lock permitting customizable bar spacing favorable in architectural applications. Compliance with safety and industry standards is a critical consideration. Accredited certifications such as ISO 9001 for quality management assure product reliability. Additionally, adherence to standards set by the American Society for Testing and Materials (ASTM) ensures consistency across parameters such as load capacity, dimensions, and tensile strength. In conclusion, choosing the correct stainless steel grating specification requires careful consideration of material grade, grating type, surface finish, fabrication technique, and compliance with safety standards. By focusing on these critical elements, businesses can procure grating solutions that not only meet functional demands but also ensure longevity and efficiency. For companies engaged in projects that necessitate robust and enduring infrastructures, understanding these specifications is not just beneficial but essential. As industries continue to evolve, staying informed on innovations and industry standards remains vital to maintaining competitive edge and operational efficiency.

The finish of the stainless steel grating also plays a vital role. Options include mill, electropolished, and powder-coated finishes, each serving distinct purposes. Mill finish is raw and subtly polished, presenting a cost-effective solution. Electropolishing enhances corrosion resistance and hygiene, perfect for the food and beverage industry by delivering a smoother surface less prone to microbial accumulation. Powder-coating offers additional protection and customizable aesthetics, particularly where color coding or branding is crucial. Fabrication techniques such as welding and swaging influence the grating's strength and performance. Welded bar grating offers robustness through fusion welding—a process integrating all contact points. This method is favored in heavy-load environments, including industrial floors and vehicle access roads. Swage-locked and press-locked grating offer alternative fabrications, with swage-lock providing a tighter connection beneficial for aesthetic constructions, and press-lock permitting customizable bar spacing favorable in architectural applications. Compliance with safety and industry standards is a critical consideration. Accredited certifications such as ISO 9001 for quality management assure product reliability. Additionally, adherence to standards set by the American Society for Testing and Materials (ASTM) ensures consistency across parameters such as load capacity, dimensions, and tensile strength. In conclusion, choosing the correct stainless steel grating specification requires careful consideration of material grade, grating type, surface finish, fabrication technique, and compliance with safety standards. By focusing on these critical elements, businesses can procure grating solutions that not only meet functional demands but also ensure longevity and efficiency. For companies engaged in projects that necessitate robust and enduring infrastructures, understanding these specifications is not just beneficial but essential. As industries continue to evolve, staying informed on innovations and industry standards remains vital to maintaining competitive edge and operational efficiency.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025