- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

feb . 10, 2025 11:38

Back to list

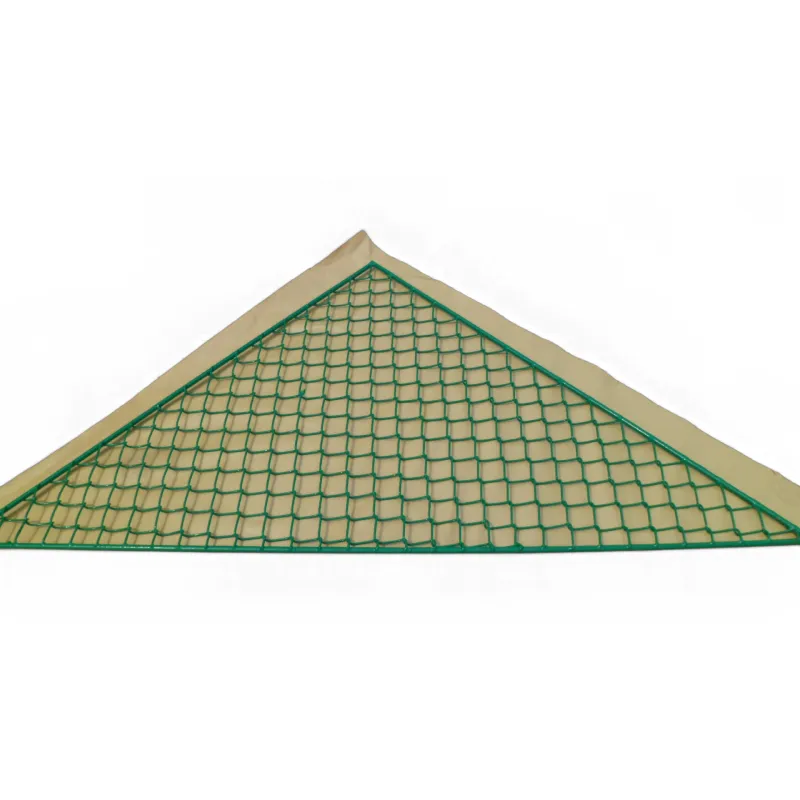

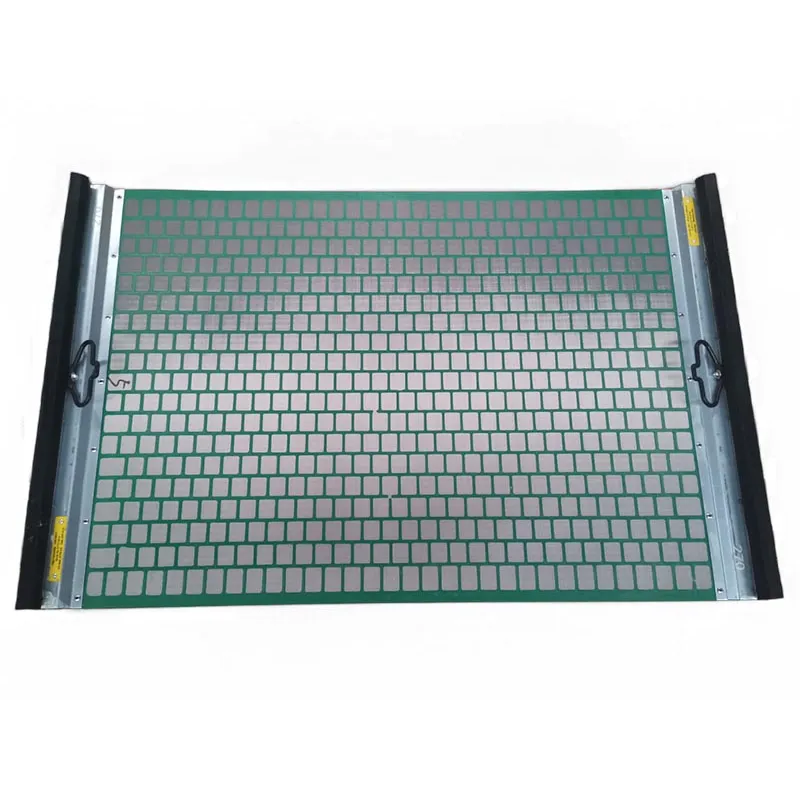

shale shaker screen

Navigating the intricate world of shale screens is essential for industries heavily reliant on efficient filtration systems. Shale screens, a critical component in the process of solid control, are the first line of defense in preventing debris and unwanted solids from contaminating valuable resources during drilling operations. Their unique role in various industrial applications makes them indispensable for ensuring optimal performance and operational efficiency.

Authoritativeness in the field of shale screen technologies is established through rigorous testing and adherence to international standards. Companies producing these screens undergo stringent quality control processes to match global benchmarks such as API RP 13C, which is an essential guideline in assessing screen performance. The authoritative knowledge comes from constant collaboration with leading research bodies and industry experts. Continuous improvement and feedback loops from field tests allow manufacturers to innovate and improve their products. Shale screens today are much more effective than their predecessors, showing advancements such as better vibration resistance, finer mesh possibilities, and the integration of smart technologies for monitoring wear and performance. Trustworthiness is arguably the most critical value for companies in the shale screen domain. Trust manifests through transparency and commitment to quality. Reputable manufacturers provide full disclosure of testing results, product specifications, and operational guidelines. They work closely with clients to ensure that each shale screen product meets the specific needs of their project. Real-world feedback illustrates the importance of trust, where maintaining long-term relationships hinges on the reliability and performance consistency of the screens. Moreover, manufacturers invest heavily in customer support and training, ensuring that on-site personnel are knowledgeable about installation and maintenance practices, thus minimizing the risk of operational failures. In conclusion, shale screens stand as a vital component within industries that rely on efficient filtration systems. With advances in technology, they continue to evolve, meeting the increasingly complex demands of modern drilling operations. The collective experience and expertise shed light on how these screens can significantly optimize performance, reduce operational costs, and safeguard the quality of drilling processes. It is through authoritative practices and trustworthy relationships that the industry continues to thrive, setting new standards and pushing the boundaries of what shale screens can achieve.

Authoritativeness in the field of shale screen technologies is established through rigorous testing and adherence to international standards. Companies producing these screens undergo stringent quality control processes to match global benchmarks such as API RP 13C, which is an essential guideline in assessing screen performance. The authoritative knowledge comes from constant collaboration with leading research bodies and industry experts. Continuous improvement and feedback loops from field tests allow manufacturers to innovate and improve their products. Shale screens today are much more effective than their predecessors, showing advancements such as better vibration resistance, finer mesh possibilities, and the integration of smart technologies for monitoring wear and performance. Trustworthiness is arguably the most critical value for companies in the shale screen domain. Trust manifests through transparency and commitment to quality. Reputable manufacturers provide full disclosure of testing results, product specifications, and operational guidelines. They work closely with clients to ensure that each shale screen product meets the specific needs of their project. Real-world feedback illustrates the importance of trust, where maintaining long-term relationships hinges on the reliability and performance consistency of the screens. Moreover, manufacturers invest heavily in customer support and training, ensuring that on-site personnel are knowledgeable about installation and maintenance practices, thus minimizing the risk of operational failures. In conclusion, shale screens stand as a vital component within industries that rely on efficient filtration systems. With advances in technology, they continue to evolve, meeting the increasingly complex demands of modern drilling operations. The collective experience and expertise shed light on how these screens can significantly optimize performance, reduce operational costs, and safeguard the quality of drilling processes. It is through authoritative practices and trustworthy relationships that the industry continues to thrive, setting new standards and pushing the boundaries of what shale screens can achieve.

Share

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025