- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

feb . 14, 2025 21:23

Back to list

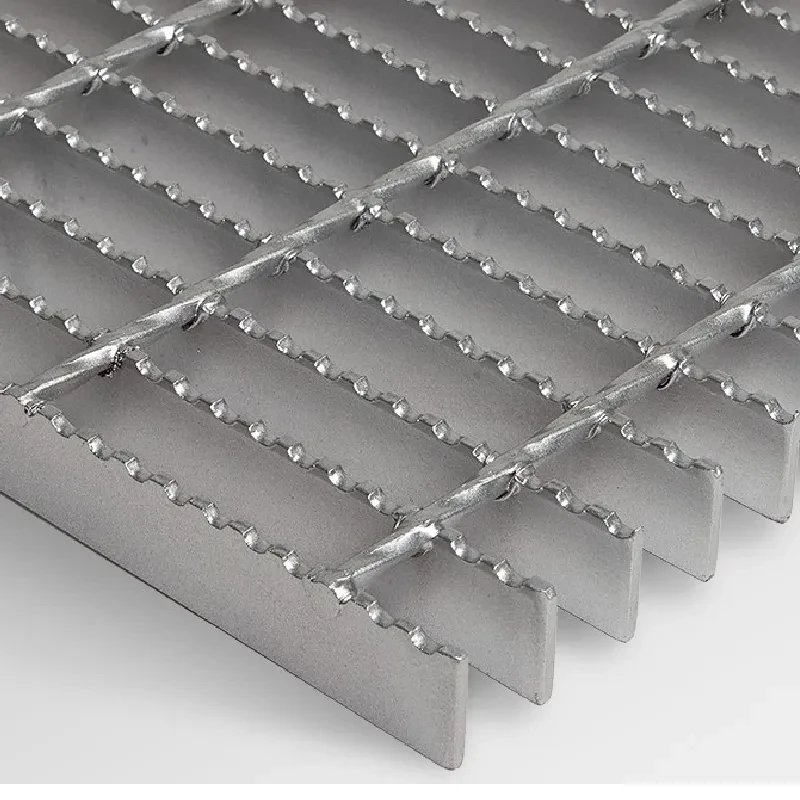

Press-Locked Steel Grating

Navigating the diverse realm of serrated grating sizes involves understanding their critical role in a broad array of industries. Each size variation offers unique advantages in specific applications, and selecting the right one is crucial for achieving optimal performance and safety in industrial environments.

Trustworthiness is built through transparency and a commitment to quality. Manufacturers and suppliers of serrated grating reinforce trust by providing detailed information about the specifications and characteristics of their products. This includes load ratings, material certifications, and compliance with industry standards. By offering comprehensive product warranties and post-purchase support, reputable companies ensure their clients have confidence in their purchasing decisions. Sizing serrated grating involves meticulous calculations and foresight. The load-bearing requirements must be anticipated accurately to select a grating that will perform effectively over its intended lifespan. Additionally, environmental considerations, such as exposure to corrosive substances or extreme temperatures, must be addressed to prevent premature degradation. The interplay of these factors highlights the critical nature of size selection in ensuring both safety and cost-effectiveness. The realm of serrated grating sizes is constantly evolving, driven by advancements in material technology and design innovations. As industries push the boundaries of what's possible, the demand for customized grating solutions grows. This evolution underscores the importance of staying informed about the latest developments and maintaining a dialogue with industry experts who can provide insights into emerging trends and technologies. In conclusion, the importance of selecting the appropriate serrated grating size cannot be understated. It requires a combination of experience, expertise, authoritativeness, and trustworthiness. Professionals in the field must navigate complex variables to provide recommendations that ensure safety, efficiency, and durability. As the industry evolves, staying informed about standards, innovations, and best practices is crucial for making informed decisions that align with both current needs and future advancements.

Trustworthiness is built through transparency and a commitment to quality. Manufacturers and suppliers of serrated grating reinforce trust by providing detailed information about the specifications and characteristics of their products. This includes load ratings, material certifications, and compliance with industry standards. By offering comprehensive product warranties and post-purchase support, reputable companies ensure their clients have confidence in their purchasing decisions. Sizing serrated grating involves meticulous calculations and foresight. The load-bearing requirements must be anticipated accurately to select a grating that will perform effectively over its intended lifespan. Additionally, environmental considerations, such as exposure to corrosive substances or extreme temperatures, must be addressed to prevent premature degradation. The interplay of these factors highlights the critical nature of size selection in ensuring both safety and cost-effectiveness. The realm of serrated grating sizes is constantly evolving, driven by advancements in material technology and design innovations. As industries push the boundaries of what's possible, the demand for customized grating solutions grows. This evolution underscores the importance of staying informed about the latest developments and maintaining a dialogue with industry experts who can provide insights into emerging trends and technologies. In conclusion, the importance of selecting the appropriate serrated grating size cannot be understated. It requires a combination of experience, expertise, authoritativeness, and trustworthiness. Professionals in the field must navigate complex variables to provide recommendations that ensure safety, efficiency, and durability. As the industry evolves, staying informed about standards, innovations, and best practices is crucial for making informed decisions that align with both current needs and future advancements.

Share

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025