- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

plastic frame shaker screen

The Rise of Plastic Frame Shaker Screens in Industrial Applications

In recent years, the demand for efficient and durable shaker screens in various industrial applications has surged. At the forefront of this evolution is the plastic frame shaker screen, which offers a plethora of advantages over traditional metal-framed options. This article delves into the technology, benefits, applications, and future trends surrounding plastic frame shaker screens.

Understanding Shaker Screens

Shaker screens are critical components in the drilling and filtration processes, used predominantly in the oil and gas industry, as well as in mining, construction, and environmental cleanup operations. Their primary function is to separate solid materials from liquids, allowing for the efficient extraction of resources while minimizing waste. The frame of these screens is designed to hold the mesh that does the actual filtering, and historically, metal frames have been the standard choice. However, advancements in material science have introduced plastic frames as a viable alternative.

Advantages of Plastic Frames

1. Weight Reduction Plastic frame shaker screens are significantly lighter than their metal counterparts. This reduction in weight translates into lower shipping costs and easier handling during installation and maintenance.

2. Corrosion Resistance One of the most notable benefits of plastic frames is their resistance to corrosion. Unlike metal, plastic does not rust or degrade when exposed to harsh chemicals and heavy saline conditions. This longevity enhances the lifespan of the shaker screens and reduces the frequency of replacements.

3. Cost-Effectiveness While the initial cost of plastic frames may be slightly higher due to the advanced materials used, their durability and reduced maintenance costs yield considerable savings in the long run. Companies can also benefit from the decreased operational downtimes associated with less frequent replacements.

4. Enhanced Performance Plastic frames allow for improved mesh tensioning and flexibility. This characteristic leads to better separation efficiency, ensuring that the desired particle sizes are accurately filtered. The design flexibility also permits better customization of screens, catering to specific project needs.

5. Environmental Sustainability Many manufacturers are now producing plastic frames from recycled materials, which not only lowers the environmental footprint of producing these screens but also aligns with the sustainability goals of many companies. Plastic frames can also be recycled at the end of their service life, further contributing to a circular economy.

Applications of Plastic Frame Shaker Screens

plastic frame shaker screen

Plastic frame shaker screens have found applications in various sectors, most notably

- Oil and Gas In drilling operations, these screens assist in separating drilling fluids from cuttings, ensuring smoother operations and less downtime

.- Mining Used in mineral processing, plastic frame screens help separate valuable minerals from waste rock, enhancing resource extraction.

- Environmental Solutions In waste management and remediation projects, these screens play a vital role in filtering contaminated water and sediments.

- Food and Beverage Industry In processes such as juice extraction or dairy fluid separation, plastic frame shaker screens are increasingly used to ensure hygiene and efficiency.

Future Trends

As industries continue to evolve, the trend towards using plastic frame shaker screens will likely gain momentum. Innovations in composite materials may lead to even stronger, lighter, and more efficient screens that meet the rigorous demands of modern industrial processes. Additionally, with the global shift towards sustainability, the development of entirely biodegradable or more easily recyclable plastic materials could significantly impact the market.

Moreover, the integration of technology such as IoT for real-time monitoring of screen performance can further improve efficiency and operational reliability.

Conclusion

Plastic frame shaker screens represent a significant advancement in filtration and separation technology across various industries. Their advantages in terms of weight, corrosion resistance, cost-effectiveness, performance, and environmental sustainability make them an increasingly preferred choice. As technological advancements continue to emerge, it is likely that plastic frame shaker screens will play a pivotal role in shaping the future of industrial applications, ensuring more efficient resource extraction and environmentally friendly operational practices.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

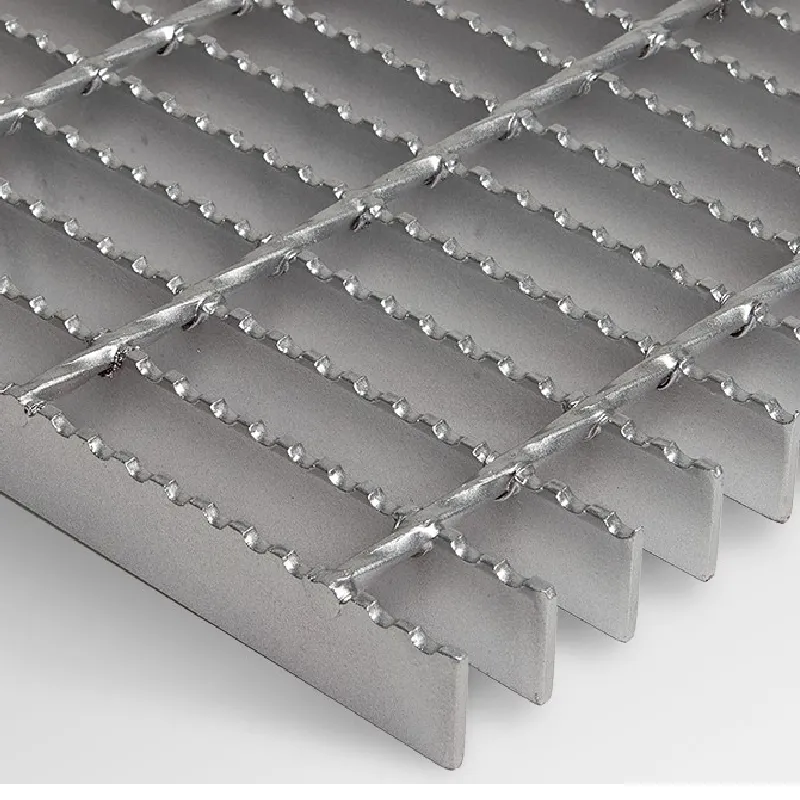

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025