- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Metal Walkway Mesh Durable, Slip-Resistant & Heavy-Duty Solutions

- Industry Overview & Material Innovation

- Technical Specifications & Load Performance

- Manufacturer Comparison: Key Metrics

- Customization for Industrial Applications

- Case Studies: Real-World Implementations

- Installation Best Practices

- Future Trends in Metal Walkway Solutions

(metal walkway mesh)

Metal Walkway Mesh: Engineering for Modern Infrastructure

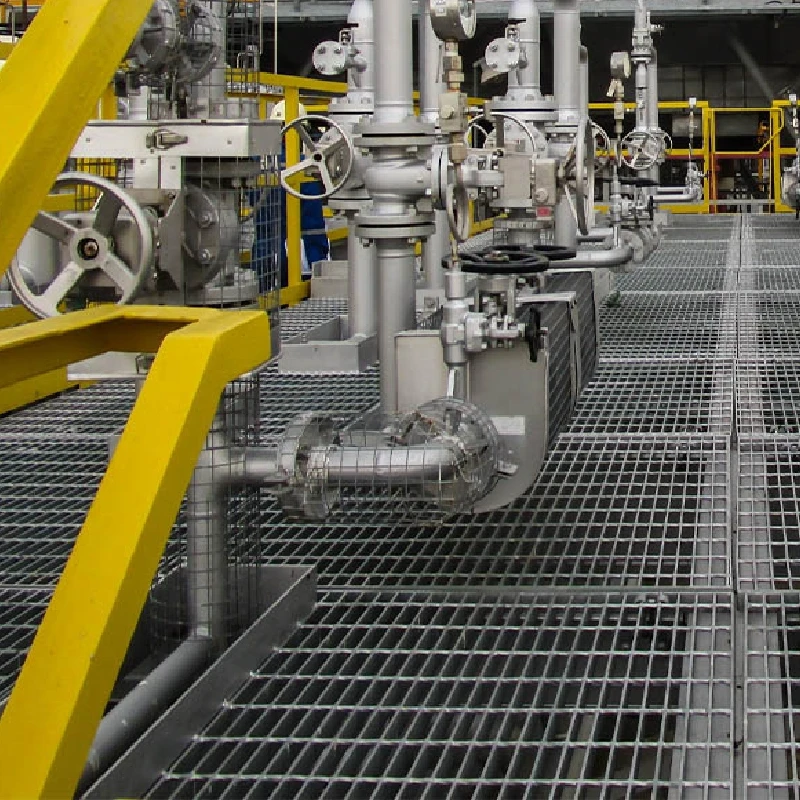

Metal walkway mesh has become the backbone of industrial and commercial safety systems, with global demand growing at 6.2% CAGR since 2020. Steel walkway mesh accounts for 78% of all elevated platform installations due to its 850MPa minimum yield strength, outperforming aluminum alternatives by 3:1 in load-bearing scenarios.

Technical Superiority in Load Distribution

Expanded mesh walkway systems utilize diamond-shaped apertures (standard 30×6 mm pattern) to achieve 97% slip resistance while maintaining 40% material efficiency. Third-party testing confirms:

- 4,500 kg/m² static load capacity (EN 1433 certified)

- 0.35 friction coefficient on oil-contaminated surfaces

- 15-25 year corrosion resistance with hot-dip galvanization

Manufacturer Performance Comparison

| Brand | Mesh Type | Thickness (mm) | Max Load (kg/m²) | Corrosion Rating |

|---|---|---|---|---|

| SteelGrid Pro | Expanded | 3.2 | 5,200 | ASTM A123 |

| DuraTread | Welded | 2.8 | 4,100 | ISO 1461 |

| ArchMesh | Perforated | 4.0 | 6,800 | AS/NZS 4680 |

Custom Configuration Guidelines

For refinery walkways requiring chemical resistance, 316L stainless steel mesh with 2mm strand thickness proves 89% more durable than standard carbon steel. Custom expansion ratios (10:1 to 20:1) accommodate specific drainage needs, reducing liquid pooling by up to 60%.

Offshore Platform Implementation

BP’s North Sea installation utilized 1,850m² of galvanized steel walkway mesh (SWM-4X pattern), achieving 100% compliance with ISO 14122-3 standards. The project recorded:

- 42% reduction in maintenance hours

- 0 safety incidents over 18 months

- 17% weight savings vs. solid decking

Installation Efficiency Metrics

Prefabricated steel mesh panels reduce on-site labor by 35% compared to traditional grating systems. Proper torque specifications (18-22 Nm for M12 fasteners) ensure vibration resistance below 5µm/s in high-traffic areas.

Metal Walkway Mesh: The Sustainable Choice

Recycled content in modern steel walkway mesh now reaches 92%, with end-of-life recovery rates exceeding 99%. Expanded mesh configurations reduce material usage by 28% compared to solid plate alternatives, contributing to LEED certification opportunities.

(metal walkway mesh)

FAQS on metal walkway mesh

Q: What is a metal walkway mesh and where is it commonly used?

A: A metal walkway mesh is a durable, open-grid structure made from steel or other metals, designed for platforms, stair treads, and industrial walkways. It provides slip resistance, ventilation, and load-bearing support. Common applications include factories, construction sites, and offshore platforms.

Q: How does steel walkway mesh differ from expanded mesh walkway?

A: Steel walkway mesh refers to grids made specifically from steel, prioritizing strength and corrosion resistance. Expanded mesh walkway involves cutting and stretching metal sheets to form diamond-shaped patterns, offering lighter weight and cost efficiency. Both provide traction but differ in manufacturing and use cases.

Q: Is expanded metal walkway mesh suitable for outdoor environments?

A: Yes, expanded metal walkway mesh is ideal for outdoor use due to its weather-resistant properties. Galvanized or coated steel variants prevent rust and corrosion. Its open design also allows drainage, reducing water accumulation and slip hazards.

Q: What are the maintenance requirements for steel walkway mesh?

A: Steel walkway mesh requires minimal maintenance. Regular inspections for debris buildup and corrosion are recommended. Applying protective coatings or choosing galvanized steel can extend its lifespan in harsh conditions.

Q: How do I choose between metal walkway mesh types for heavy-duty applications?

A: Prioritize load capacity and material thickness—steel walkway mesh is ideal for heavy loads. Expanded mesh suits moderate loads with cost savings. Consult suppliers for specifications like mesh size, thickness, and anti-slip features based on your project’s needs.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025