- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Understanding Grating and Galvanized Materials in Construction and Industrial Applications

Understanding Grating Galvanized A Comprehensive Overview

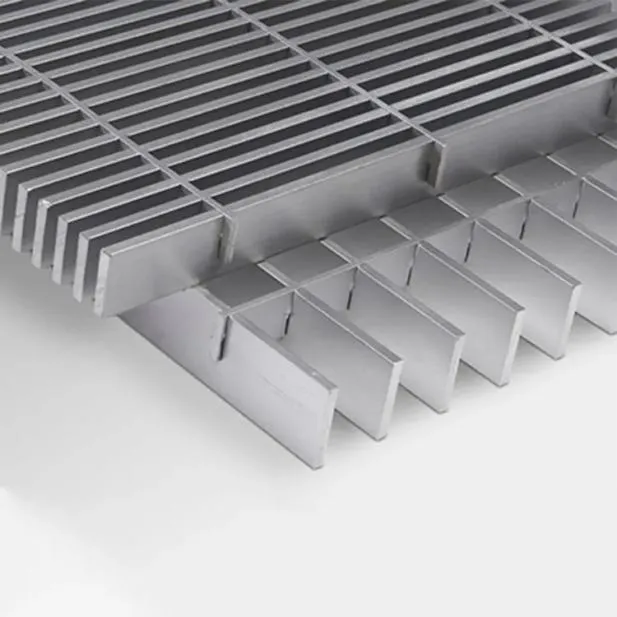

Grating galvanized is an essential component in various industries, known for its strength, durability, and resistance to corrosion. It serves as a vital element in construction, manufacturing, and infrastructural projects, providing safe and reliable access as well as support in various applications. This article aims to explore the characteristics, benefits, and applications of galvanized grating, shedding light on why it is a preferred choice in many sectors.

What is Galvanized Grating?

Galvanized grating refers to a type of flooring material made from metal bars that are spaced apart to create a grid-like surface. Before it is fabricated into grating, the metal, typically carbon steel, undergoes a galvanization process. This involves coating the steel with a layer of zinc to enhance its resistance to rust and corrosion. The result is a strong, lightweight, and weather-resistant material that is ideal for outdoor and industrial applications.

The Galvanization Process

The galvanization process can be achieved through several methods, including hot-dip galvanizing and electro-galvanizing.

1. Hot-Dip Galvanizing In this method, the steel is immersed in molten zinc, allowing for a thick coating that provides long-lasting protection. This process ensures that the zinc adheres tightly to the steel, creating a robust barrier against environmental factors. 2. Electro-Galvanizing This technique utilizes an electrochemical process to apply a zinc coating to the steel. While it provides a thinner layer of zinc compared to hot-dip galvanizing, it still offers decent corrosion resistance, making it suitable for less demanding environments.

Advantages of Galvanized Grating

1. Corrosion Resistance The primary advantage of galvanized grating is its exceptional resistance to corrosion. The zinc coating protects the steel from moisture, chemicals, and other corrosive elements, making it ideal for environments such as factories, wastewater treatment plants, and marine applications.

grating galvanized

2. Strength and Durability Galvanized grating is known for its strength-to-weight ratio. It offers significant load-bearing capabilities while remaining lightweight, which simplifies the installation process and reduces transportation costs.

3. Low Maintenance With its resilient surface, galvanized grating requires little maintenance. The protective zinc layer significantly prolongs its lifespan, reducing the need for regular replacements and repairs.

4. Safety and Slip Resistance Many types of galvanized grating come with a textured surface or are designed with a non-slip finish, contributing to safer walking surfaces. This feature is crucial in areas that are prone to spills or frequent wet conditions.

Applications of Galvanized Grating

Galvanized grating is utilized in a broad range of applications across various sectors

- Industrial Flooring It is commonly used in factories and warehouses where heavy machinery is present, providing a durable walkway or working surface. - Platforms and Walkways Galvanized grating is ideal for elevating platforms, allowing for efficient airflow, light penetration, and safe passage over hazardous areas. - Drainage Covers Its strength makes it suitable for grates used in drainage systems, providing safety while allowing water to flow through. - Bridge Decks In civil engineering, galvanized grating is used in bridge construction due to its ability to withstand heavy loads and harsh environmental conditions.

Conclusion

Grating galvanized is a versatile and essential material in modern industrial applications. Its unique properties, including superior corrosion resistance, strength, and low maintenance requirements, make it an optimal choice for various applications. As industries continue to evolve, the importance of reliable materials like galvanized grating will only increase, reinforcing its position as a cornerstone in construction and manufacturing sectors. Whether for flooring, platforms, or drainage solutions, galvanized grating proves itself as a dependable option that meets the diverse needs of today's infrastructure.

-

Welded Steel Grating: The Strong Foundation for Industrial SafetyNewsJul.16,2025

-

Strong and Safe: Swaged Grating SolutionsNewsJul.16,2025

-

Smart Choice For Industrial Safety MeshNewsJul.16,2025

-

Press-Locked Steel Grating: The Ultimate in Strength and SafetyNewsJul.16,2025

-

Keep Worksites Safer With Practical NettingNewsJul.16,2025

-

Helideck Safety Nets: Your First Line of DefenseNewsJul.16,2025