- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

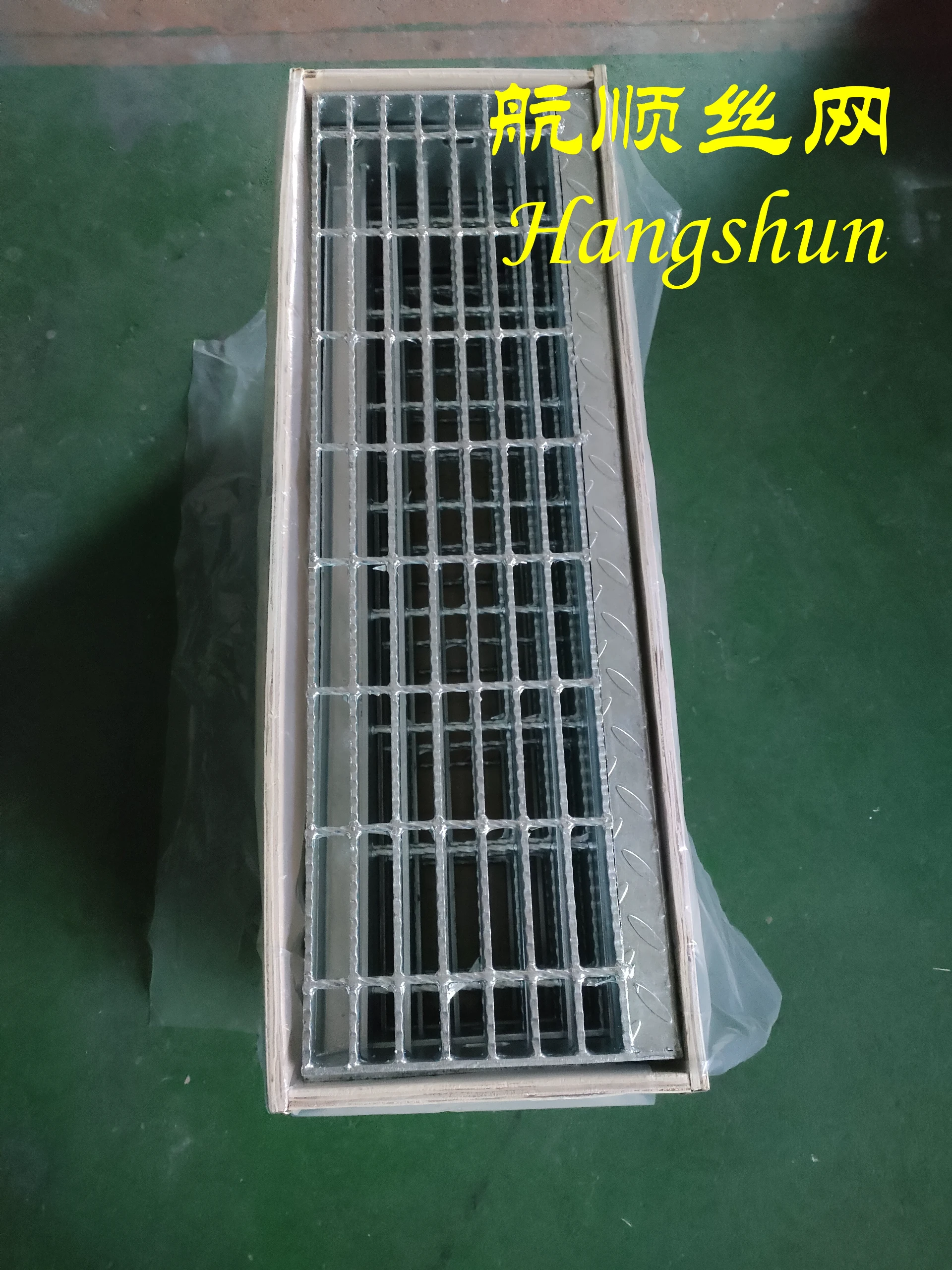

Galvanized Steel Bar Grating High-Strength & Low-Cost Solutions

- Overview of Galvanized Steel Bar Grating

- Technical Advantages & Performance Data

- Manufacturer Comparison: Load Capacity & Pricing

- Customization Options for Industrial Needs

- Cost Efficiency & Long-Term Value

- Application Case Studies

- Why Galvanized Steel Bar Grating Endures

(galvanized steel bar grating)

Understanding Galvanized Steel Bar Grating

Galvanized steel bar grating is a high-strength, corrosion-resistant material fabricated from carbon steel coated with zinc. Widely used in industrial walkways, platforms, and drainage systems, it combines durability with safety. The galvanization process extends lifespan by 4–6× compared to untreated steel, reducing maintenance costs by up to 40% annually.

Technical Advantages & Performance Metrics

Hot-dip galvanizing creates a zinc layer of 80–100 microns, ensuring resistance to harsh chemicals and UV exposure. Independent tests show:

- Load capacity: 1,200–5,000 lbs/ft² (varies with bar spacing)

- Slip resistance: 25% higher than fiberglass alternatives

- Temperature tolerance: -40°F to 120°F without deformation

Manufacturer Comparison: Specifications & Pricing

| Vendor | Thickness (mm) | Max Load (lbs/ft²) | Corrosion Resistance (ASTM B117) | Price per sq.ft ($) |

|---|---|---|---|---|

| Vendor A | 6.0 | 4,200 | 1,500 hours | 18.50 |

| Vendor B | 5.5 | 3,800 | 1,200 hours | 15.90 |

| Vendor C | 7.2 | 5,100 | 2,000 hours | 22.75 |

Tailored Solutions for Industry Demands

Customizable parameters include:

- Bar spacing: 1" to 6" configurations

- Surface treatments: Optional serrated edges for enhanced slip resistance

- Panel sizes: Up to 24' lengths for seamless installation

Cost-Benefit Analysis Over 10 Years

While galvanized bar grating costs 20–30% more upfront than painted steel, its 50-year service life cuts replacement expenses by 60–75%. For a 10,000 sq.ft project:

- Initial investment: $185,000 (Vendor A)

- Maintenance savings: $62,000 (vs. non-galvanized)

- ROI period: 3.8 years

Real-World Implementation Scenarios

Case 1: A petrochemical plant replaced carbon steel with galvanized serrated bar grating, reducing fall incidents by 34% and saving $280,000 in 5 years through eliminated repainting.

Case 2: A municipal wastewater facility utilized 2" spaced grating, achieving 98% debris filtration while withstanding pH 2–12 exposure for 12+ years.

Why Galvanized Steel Bar Grating Dominates

With 3.1% annual growth in the structural steel market (2023–2030), galvanized steel bar grating

remains pivotal for infrastructure projects. Its fusion of adaptive manufacturing, cost predictability, and regulatory compliance (OSHA/ISO 14122) ensures lasting relevance across industries.

(galvanized steel bar grating)

FAQS on galvanized steel bar grating

Q: What is galvanized steel bar grating used for?

A: Galvanized steel bar grating is primarily used for industrial flooring, walkways, and platforms due to its durability, slip resistance, and corrosion protection. It’s ideal for outdoor or high-moisture environments.

Q: How does galvanized bar grating cost compare to stainless steel?

A: Galvanized bar grating cost is typically lower than stainless steel, making it a budget-friendly choice for corrosion-resistant applications. Prices vary based on thickness, spacing, and panel size.

Q: What are the benefits of galvanized serrated bar grating?

A: Galvanized serrated bar grating provides enhanced slip resistance, especially in wet or oily conditions. The serrated surface improves safety, while the galvanization adds long-lasting rust protection.

Q: How long does galvanized steel bar grating last?

A: Properly maintained galvanized steel bar grating can last 20-50 years, depending on environmental exposure. The zinc coating prevents rust, extending its lifespan in harsh conditions.

Q: Can galvanized bar grating be customized for specific projects?

A: Yes, galvanized bar grating can be customized in bar spacing, thickness, and panel dimensions to meet load-bearing requirements. Serrated or smooth surfaces are also available based on safety needs.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025