- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

High-Quality Shaker Screens Available for Purchase with Competitive Pricing and Fast Shipping Options

Exploring the Market for Shaker Screens A Comprehensive Guide

Shaker screens play an essential role in numerous industries, particularly in the fields of oil and gas, construction, and mining. These screens are crucial for separating particles of different sizes, thus ensuring the efficiency and effectiveness of various processes. With the rising demand for shaker screens in the market, there are numerous options available for sale, each designed to cater to specific needs and requirements.

What are Shaker Screens?

Shaker screens, also known as vibrating screens or shale shakers, are mechanical devices that use vibration to separate and filter materials. They are primarily used in drilling operations to separate drilling mud from cuttings. By doing so, they help maintain the properties of the drilling fluid, reduce waste, and enhance operational efficiency. Shaker screens vary in design, covering deck sizes, mesh types, and materials used, making them suitable for various applications across different industries.

Types of Shaker Screens Available for Sale

1. Linear Motion Shaker Screens These screens operate with a linear motion and are characterized by their high capacity and efficiency. They are ideal for applications requiring rapid separation of materials and are commonly used in oil and gas drilling.

2. Circular Motion Shaker Screens This type of screen uses a circular motion to facilitate the separation process. They are generally employed for less demanding applications and are known for their robustness and simplicity in design.

3. Dewatering Screens Designed specifically to remove water from materials, these screens are widely utilized in industries such as mining and construction. Their construction allows for efficient drainage while effectively retaining the solid material.

4. Tensioned Screens These are designed to be tensioned across a frame, providing optimal performance and durability. They are often used in applications where efficient cut size control is necessary.

Factors to Consider When Buying Shaker Screens

When looking for shaker screens for sale, it is crucial to consider several factors to ensure you select the right one for your needs

shaker screen for sale

- Material Compatibility Different shaker screens are made from various materials including stainless steel, polyurethane, and other composites. It is essential to choose a material compatible with the substances being screened.

- Mesh Size The mesh size of the screen determines the particle size that can be filtered

. Different applications may require different mesh sizes, so assessing your specific needs is vital.- Durability and Maintenance Consider the screen's durability and the maintenance requirements. High-quality screens may cost more upfront but can provide better longevity and require less frequent replacement.

- Cost and Budget Prices for shaker screens can vary widely. It’s essential to set a budget and find a balance between cost and quality.

Where to Find Shaker Screens for Sale

Shaker screens can be purchased from a variety of sources, including

- Manufacturers Many manufacturers produce and sell shaker screens directly. This option often provides the benefit of customization to fit specific requirements.

- Distributors and Suppliers Specialized distributors may offer a wide range of shaker screens from various manufacturers, making it easier to compare different products.

- Online Marketplaces Websites such as eBay or industrial equipment marketplaces often have listings for new and used shaker screens, providing potential cost savings.

Conclusion

In conclusion, shaker screens are vital components in various industrial processes, and the market offers a range of options for sale. Understanding the different types of shaker screens, their specifications, and factors to consider when purchasing can significantly enhance operational efficiency. Whether you're in oil and gas, mining, or construction, investing in the right shaker screen can yield significant benefits in the long run. As you explore your options, remember to assess your specific requirements and consider reaching out to manufacturers or distributors for further assistance.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

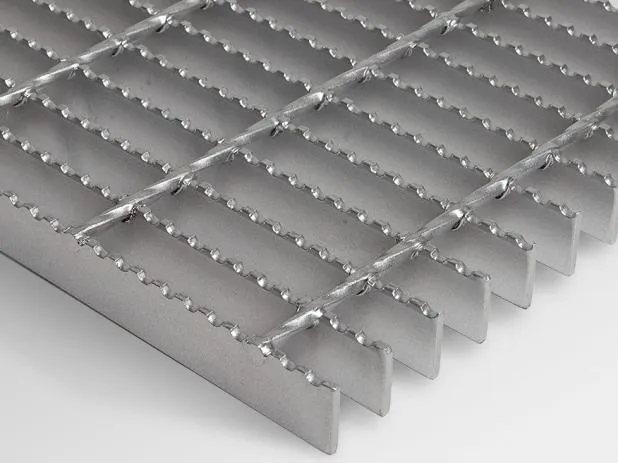

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025