- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

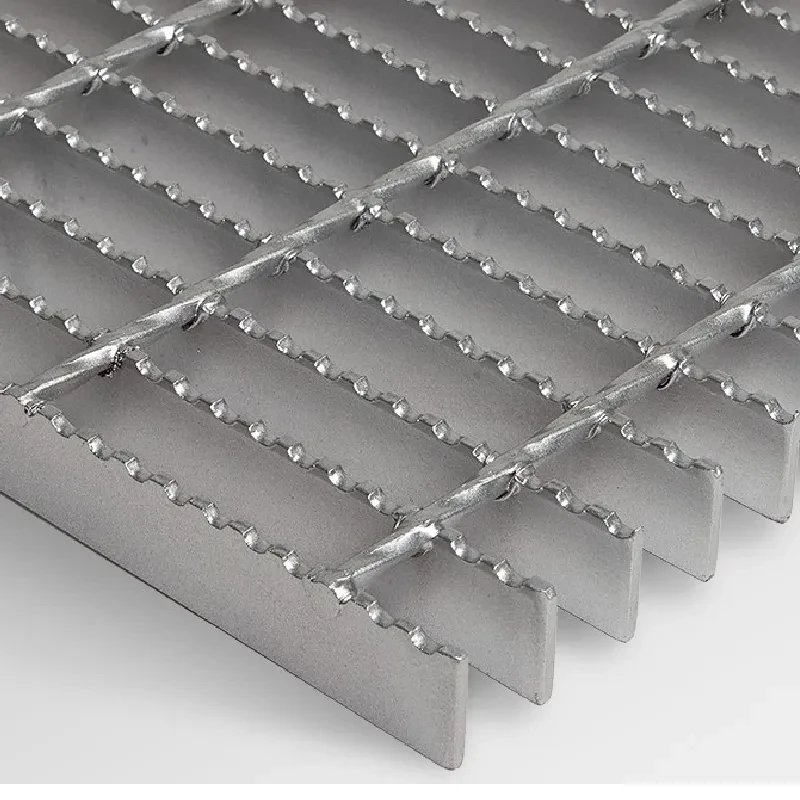

galvanized grating steps

Understanding Galvanized Grating Steps A Comprehensive Guide

Galvanized grating steps are integral components in many industrial and commercial applications, providing safe and reliable access across various platforms and structures. This article will delve into the importance, production, benefits, and applications of galvanized grating steps, offering a comprehensive overview of why they are a crucial element in modern construction and infrastructure projects.

What are Galvanized Grating Steps?

Galvanized grating steps are typically manufactured from steel or other metals that have undergone a galvanization process. This treatment involves coating the metal with zinc to prevent rust and corrosion, significantly enhancing its durability and lifespan. The grating is designed to provide a slip-resistant surface, ensuring safety in environments where moisture or debris might create hazardous conditions.

Importance of Galvanized Grating Steps

Safety is paramount in any industrial setting, and galvanized grating steps play a crucial role in ensuring the safe movement of personnel and equipment. These steps offer superior traction compared to traditional flat surfaces, minimizing the risk of slips and falls. Furthermore, their open design allows for water drainage and debris removal, making them particularly effective in outdoor environments or areas prone to spills.

Production Process of Galvanized Grating Steps

The production of galvanized grating steps begins with the selection of raw materials, usually steel bars. These bars are fabricated into a grating system through a process that involves welding and cutting. The next step is galvanization, where the grating is submerged in molten zinc. This process creates a robust, corrosion-resistant layer that adheres to the metal, providing long-lasting protection against environmental elements. The final product undergoes quality checks to ensure it meets safety and performance standards.

Benefits of Galvanized Grating Steps

1. Durability The galvanization process significantly prolongs the life span of grating steps, making them a cost-effective solution over time. They can withstand harsh weather conditions and resist deterioration from chemicals or other corrosive substances.

galvanized grating steps

2. Safety With their slip-resistant surface, galvanized grating steps offer enhanced safety for workers. The design eases footing, reducing the possibility of accidents in high-traffic areas.

3. Low Maintenance The protective zinc coating requires minimal maintenance, making galvanized grating steps an excellent choice for facilities looking to reduce upkeep costs.

4. Environmental Sustainability Steel is a recyclable material, and the use of galvanized grates contributes to more sustainable construction practices. As they can be reused or recycled at the end of their lifespan, they align with modern environmental standards.

5. Versatility Galvanized grating steps can be customized in terms of size, shape, and load-bearing capabilities, enabling their application across diverse industries such as construction, manufacturing, and transportation.

Applications

Galvanized grating steps are widely used in various applications, including

- Industrial Facilities They are commonly found in factories and warehouses where heavy machinery is operated. - Commercial Buildings Office buildings often incorporate these steps for their staircases and access platforms. - Outdoor Spaces Parks, playgrounds, and public squares utilize galvanized grating steps for their aesthetics and durability against weather conditions. - Transportation They are often used in platforms and walkways of train stations and airports for safe navigation.

Conclusion

Galvanized grating steps represent a blend of safety, durability, and versatility that is critical in today's industrial and commercial landscapes. Their ability to provide safe access while resisting corrosion makes them an invaluable asset in a variety of settings. As industries continue to prioritize safety and sustainability, the demand for galvanized grating steps is likely to grow, solidifying their position as a staple in construction and infrastructure development. Whether in factories, commercial establishments, or outdoor venues, galvanized grating steps will continue to play a significant role in promoting safety and efficiency for years to come.

-

Welded Steel Bar Grating: The Strongest Choice for Industrial FlooringNewsMay.21,2025

-

Steel Grating for Sale: The Ultimate Anti-Slip SolutionNewsMay.21,2025

-

Steel Frame Shaker Screens: Unmatched Durability for Demanding OperationsNewsMay.21,2025

-

Shaker Screens: Your Ultimate Solution for Oil & Gas FiltrationNewsMay.21,2025

-

Press Locked Steel Grating: The Smarter Choice for Heavy-Duty FlooringNewsMay.21,2025

-

Helicopter Deck Safety Nets: Protect Your Crew and EquipmentNewsMay.21,2025