- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Φεβ . 10, 2025 12:41

Back to list

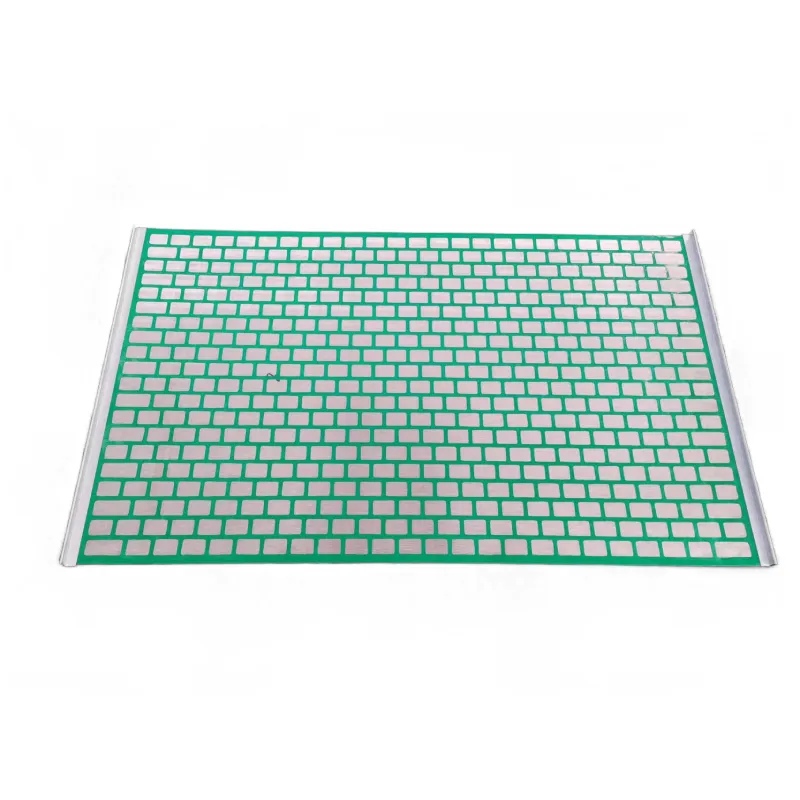

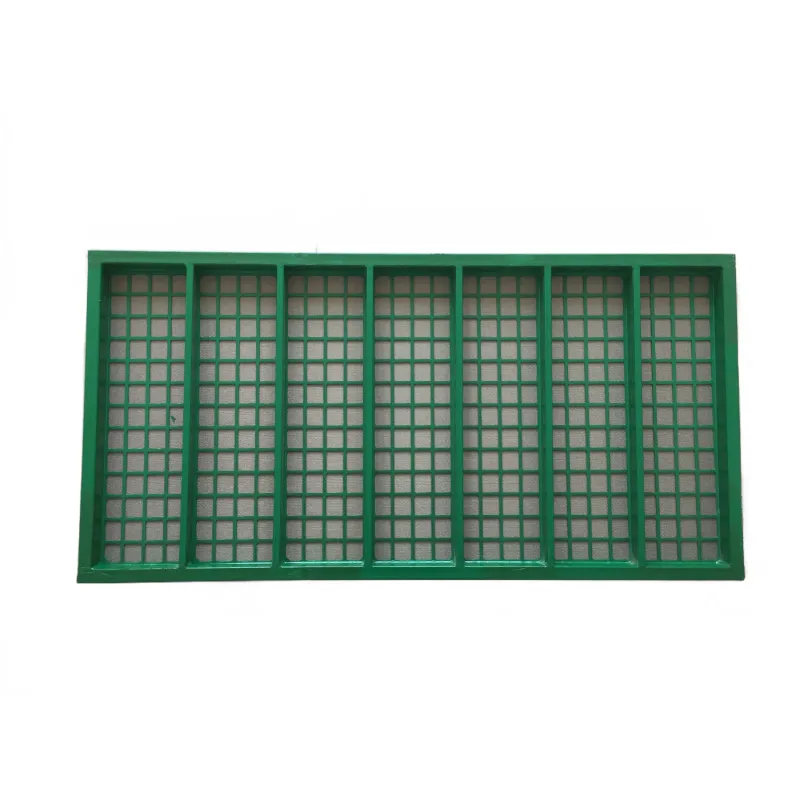

3D Shaker Screen

Derrick pyramid screens stand at the forefront of the solids control industry, offering unparalleled efficiency and adaptability in the separation of solids from drilling fluids. As a key component of shale shakers used in the oil and gas industries, these screens play a pivotal role in ensuring the quality and consistency of drilling operations.

One of the standout features of Derrick pyramid screens is their capacity to maintain high throughput rates without compromising the quality of separation. This factor is critical in high-stakes drilling operations where time and precision are critical. Operators benefit from reduced non-productive time, lower fluid loss, and improved drilling fluid recovery rates. Beyond the technical specifications, the expertise behind Derrick pyramid screens is built upon decades of innovation and commitment to quality. Derrick Corporation, the pioneer in this technology, leads the industry with cutting-edge research and development. Their dedication to advancing solids control technologies underpins the trust that operators place in their products. Choosing Derrick pyramid screens is not merely a selection of a product but a strategic decision to enhance operational excellence. End-users have reported not only immediate improvements in their drilling operations but also long-term benefits such as reduced waste management costs and minimized environmental footprint. This positions Derrick pyramid screens as not just a component of the solids control system but a critical investment in operational sustainability. In conclusion, Derrick pyramid screens are a testament to effective engineering and a commitment to excellence in the solids control industry. Their blend of innovative design, robust materials, and expert manufacturing ensures unparalleled performance, making them indispensable in modern drilling operations. Embracing Derrick pyramid screens means investing in a solution that guarantees reliability, efficiency, and long-term operational success.

One of the standout features of Derrick pyramid screens is their capacity to maintain high throughput rates without compromising the quality of separation. This factor is critical in high-stakes drilling operations where time and precision are critical. Operators benefit from reduced non-productive time, lower fluid loss, and improved drilling fluid recovery rates. Beyond the technical specifications, the expertise behind Derrick pyramid screens is built upon decades of innovation and commitment to quality. Derrick Corporation, the pioneer in this technology, leads the industry with cutting-edge research and development. Their dedication to advancing solids control technologies underpins the trust that operators place in their products. Choosing Derrick pyramid screens is not merely a selection of a product but a strategic decision to enhance operational excellence. End-users have reported not only immediate improvements in their drilling operations but also long-term benefits such as reduced waste management costs and minimized environmental footprint. This positions Derrick pyramid screens as not just a component of the solids control system but a critical investment in operational sustainability. In conclusion, Derrick pyramid screens are a testament to effective engineering and a commitment to excellence in the solids control industry. Their blend of innovative design, robust materials, and expert manufacturing ensures unparalleled performance, making them indispensable in modern drilling operations. Embracing Derrick pyramid screens means investing in a solution that guarantees reliability, efficiency, and long-term operational success.

Share

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025