- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Advantages and Applications of Structural Steel Grating in Modern Construction

The Advantages and Applications of Structural Steel Grating

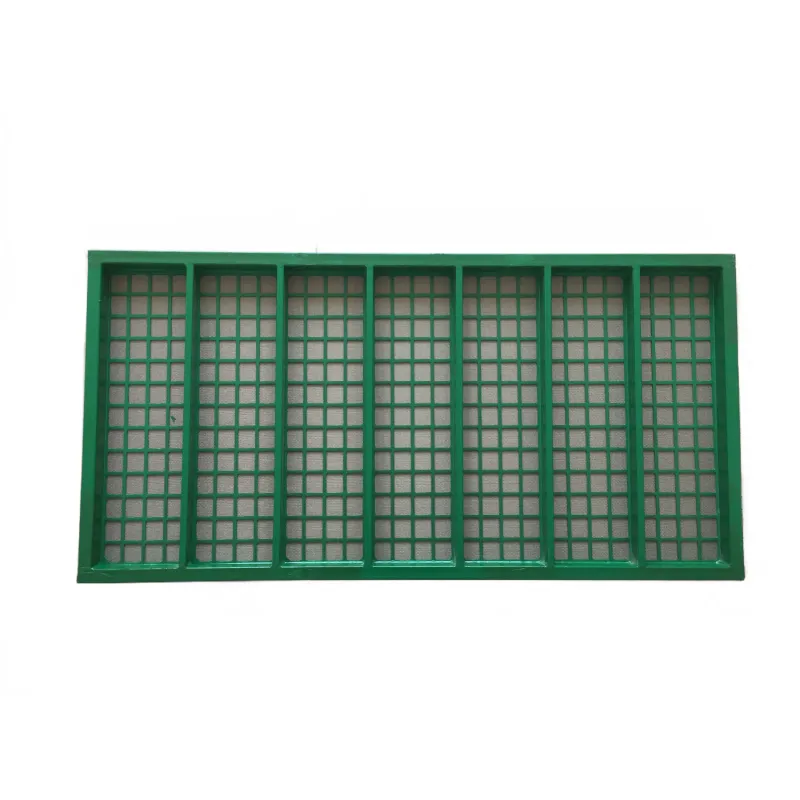

Structural steel grating is a versatile and indispensable material widely used in various industrial and commercial applications. Known for its strength, durability, and slip-resistance, steel grating has become a go-to solution for flooring, walkways, drainage covers, and much more. This article explores the benefits, applications, and considerations surrounding structural steel grating.

What is Structural Steel Grating?

Structural steel grating is a type of open grid flooring used to support pedestrian traffic, provide ventilation, and allow light to penetrate. Typically made from carbon steel, stainless steel, or aluminum, it consists of a series of horizontal and vertical bars welded together to form a strong, lightweight platform. The spacing between the bars can vary, allowing for customizable applications based on specific requirements.

Benefits of Steel Grating

1. Strength and Durability One of the primary advantages of structural steel grating is its impressive strength-to-weight ratio. It can support heavy loads while being significantly lighter than solid flooring materials. This attribute makes it particularly valuable in environments that demand both robustness and efficiency.

2. Slip Resistance Safety is paramount in industrial and commercial settings, and steel grating provides excellent slip resistance. Many types come with serrated edges, enhancing traction and minimizing potential accidents. This feature is especially crucial in areas prone to moisture, such as food processing plants or outdoor walkways.

3. Low Maintenance Unlike traditional flooring solutions, structural steel grating is easy to clean and maintain. Its open design prevents the accumulation of debris and water, reducing the risk of corrosion and contamination. With regular inspections and maintenance, steel grating can last for decades.

4. Versatility Steel grating can be used in various applications, from factory floors to pedestrian walkways. Its adaptability allows it to be utilized in demanding environments such as oil rigs, power plants, and chemical facilities, as well as in commercial settings like shopping malls and airports.

5. Customizability Steel grating is available in various sizes, shapes, and materials. This flexibility allows designers and engineers to customize grating solutions based on specific project needs, whether it's for load-bearing capacity, aesthetic appeal, or environmental considerations.

Applications of Structural Steel Grating

Structural steel grating can be found across numerous industries. Here are some prominent applications

structural steel grating

- Industrial Flooring In manufacturing plants and warehouses, steel grating provides a robust and durable flooring solution that can withstand heavy machinery and foot traffic

.- Walkways and Platforms Steel grating is commonly used to create walkways and platforms that allow employees to navigate safely over elevated areas or hazardous zones.

- Drainage Covers Due to its open-grid design, steel grating is ideal for drainage covers, enabling water and other liquids to flow through while preventing large debris from entering drainage systems.

- Stair treads and Ramps Safety is critical when it comes to staircases and ramps. Steel grating's slip-resistant properties make it an ideal choice for these areas, ensuring that users can ascend and descend safely.

- Architectural Elements Beyond industrial uses, structural steel grating is also employed in architecture as an aesthetic feature. It can be used in facades, ceilings, and landscaping, adding a modern touch to various designs.

Considerations When Using Steel Grating

While structural steel grating offers numerous advantages, several factors should be considered when selecting and implementing this material

- Load Requirements It's essential to understand the load requirements for specific applications. Engineers should calculate the weight that the grating will need to support, taking into account both static and dynamic loads.

- Corrosion Resistance Depending on the environment, it may be necessary to select corrosion-resistant materials, such as stainless steel or hot-dipped galvanized steel, to prevent degradation over time.

- Installation Proper installation is critical to ensuring safety and functionality. It is advisable to consult with professionals to ensure that the grating is appropriately secured and meets industry standards.

Conclusion

Structural steel grating is a robust, versatile, and safe solution for many applications across different industries. Its benefits, from strength and slip resistance to low maintenance and customization, make it a preferred choice among engineers and architects. By carefully considering the specific needs of a project, users can effectively leverage the advantages of structural steel grating to enhance safety and functional performance in their environments.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025