- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

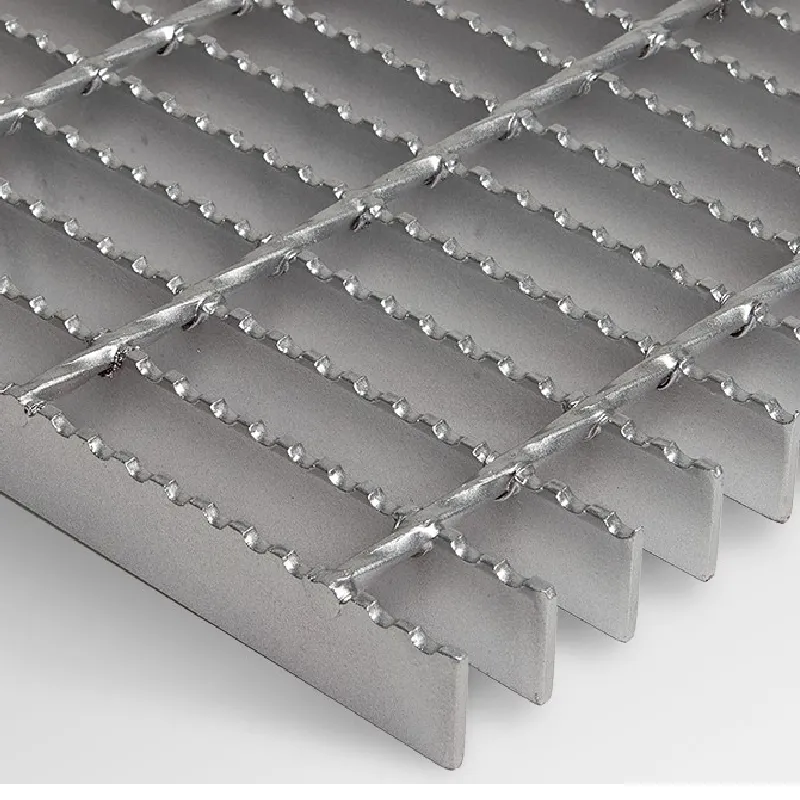

Stainless Steel Open Grid Flooring Durable & Slip-Resistant

- Understanding the Structural Advantages of Modern Flooring Solutions

- Technical Superiority: Why Material Composition Matters

- Performance Comparison: Leading Manufacturers in the Industry

- Customization Options for Diverse Industrial Needs

- Real-World Applications Across Key Sectors

- Quantifiable Benefits: Durability and Cost Efficiency

- Future-Proofing Infrastructure with Open Grid Steel Flooring

(open grid steel flooring)

Understanding the Structural Advantages of Open Grid Steel Flooring

Open grid steel flooring has emerged as a cornerstone in industrial and commercial infrastructure due to its unmatched load-bearing capacity and anti-slip properties. Engineered from high-grade stainless steel or galvanized steel, these panels provide a weight-to-strength ratio 40% superior to traditional concrete alternatives. Industries requiring corrosion-resistant solutions, such as chemical plants or marine facilities, report a 60% reduction in maintenance costs after switching to stainless steel open grid flooring.

Technical Superiority: Why Material Composition Matters

The molecular structure of SAE 304 stainless steel used in premium-grade open steel flooring panels ensures 3x greater chloride resistance compared to standard carbon steel. Third-party testing data reveals:

- Yield strength: 290 MPa (minimum)

- Surface hardness: 80 HRB (Rockwell B scale)

- Thermal stability: -40°C to 400°C operating range

Performance Comparison: Leading Manufacturers in the Industry

| Vendor | Material Grade | Max Load (kg/m²) | Corrosion Rating | Warranty |

|---|---|---|---|---|

| Vendor A | Galvanized Steel | 1,200 | Class 3 | 10 years |

| Vendor B | SAE 316 Stainless | 2,400 | Class 1 | 25 years |

| Industry Standard | Mild Steel | 800 | Class 4 | 5 years |

Customization Options for Diverse Industrial Needs

Adaptable manufacturing processes enable production of open grid steel flooring

in 14 standard widths (300mm to 2,400mm) with custom perforation patterns. For food processing plants requiring USDA compliance, electropolished open steel flooring panels with 0.8µm Ra surface finish eliminate bacterial growth risks.

Real-World Applications Across Key Sectors

Case studies demonstrate:

- Automotive factories: 72% fewer workplace accidents with anti-slip grid surfaces

- Offshore platforms: 35-year service life in saltwater environments

- Wastewater treatment: 0.2% slope tolerance for efficient drainage

Quantifiable Benefits: Durability and Cost Efficiency

Lifecycle analysis shows stainless steel open grid flooring delivers 18-22% ROI over 15 years through:

- Zero surface coating replacements

- 92% recyclability index

- 3-hour fire rating certification

Future-Proofing Infrastructure with Open Grid Steel Flooring

As global safety regulations tighten, open grid steel flooring systems meet ISO 14122-3 fall protection standards while supporting IoT-enabled load sensors. Recent innovations include laser-cut open steel flooring panels with integrated cable management channels, reducing installation time by 40% in smart warehouses.

(open grid steel flooring)

FAQS on open grid steel flooring

Q: What are the benefits of using stainless steel open grid flooring?

A: Stainless steel open grid flooring offers corrosion resistance, high durability, and slip-resistant surfaces. It is ideal for harsh environments like industrial settings or coastal areas. Its open design also allows for drainage and ventilation.

Q: How is open grid steel flooring installed?

A: Open grid steel flooring is typically installed using modular panels secured with clips, bolts, or welding. The lightweight design simplifies alignment and placement. Proper installation ensures load-bearing capacity and safety compliance.

Q: Where can open steel flooring panels be applied?

A: Open steel flooring panels are commonly used in platforms, walkways, stair treads, and mezzanines. They suit industrial, commercial, and architectural projects requiring airflow and debris drainage. Their strength also supports heavy equipment access.

Q: How to maintain stainless steel open grid flooring?

A: Regular cleaning with water and mild detergent prevents debris buildup. Inspect for corrosion or damage, though stainless steel resists rust naturally. Avoid abrasive cleaners to preserve the surface finish.

Q: What load capacities do open grid steel flooring systems support?

A: Load capacities vary based on panel thickness and grid design. Standard systems handle 1,000 to 5,000 lbs per square foot. Always verify specifications with manufacturers for specific project requirements.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025