- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

jan . 14, 2025 12:23

Back to list

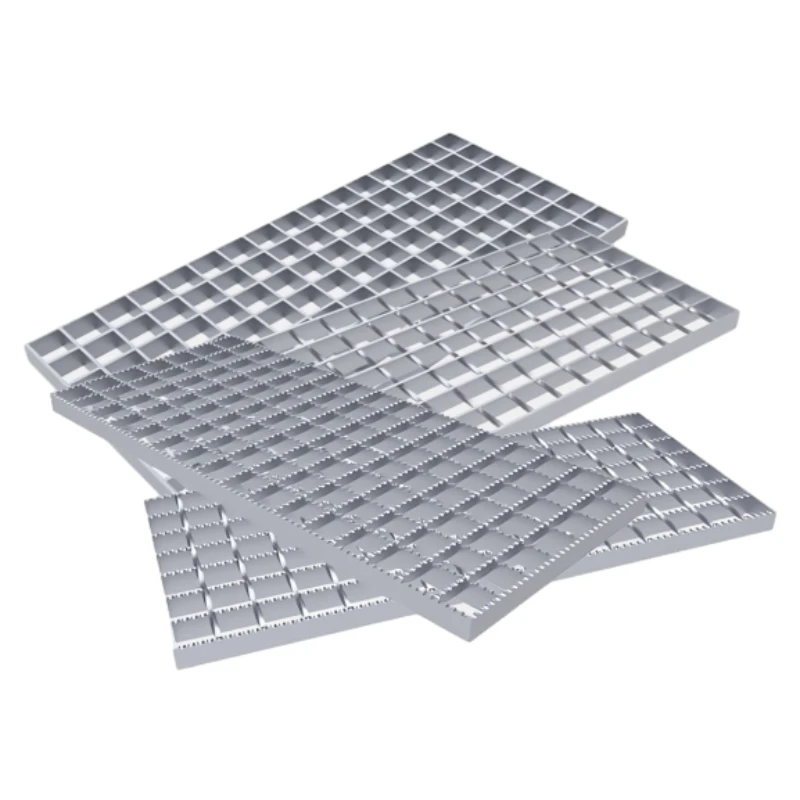

industrial shaker screen

Industrial shaker screens are essential components in various industries, playing a critical role in material separation and processing. Their efficiency and reliability affect the productivity and operational cost of procedures ranging from mining to food processing. As someone deeply ingrained in the intricacies of industrial shaker screens, I can share insights grounded in deep experience, showcasing the value these tools bring to modern industrial applications.

Innovative developments in industrial shaker screens also demonstrate a commitment to expertise and continuous improvement. Recent advancements include modular screen designs that allow for easy replacement and maintenance, minimizing downtime. Other innovations involve the incorporation of technology, such as automatic detection systems that alert operators to potential issues before they result in costly repairs. These advancements not only optimize operational efficiency but also align with sustainability efforts by minimizing resource waste and energy consumption. Furthermore, the choice of provider for shaker screens can significantly affect an operation’s success. Providers that stand out in expertise usually offer comprehensive support, from pre-sale consultancy to after-sales service, ensuring the screen's optimal performance throughout its life span. This holistic approach builds a strong sense of trust with clients, encouraging long-term partnerships and steady industrial growth. In conclusion, the importance of industrial shaker screens in processing industries cannot be overstated. Their performance has a direct impact on productivity, operational costs, and the quality of the end product. By understanding the complexities of screen selection, maintenance, and innovation, industries can harness the full potential of this tool. Insights from seasoned experts drive the proper application of shaker screens, guaranteeing that businesses remain competitive while optimizing their processing practices.

Innovative developments in industrial shaker screens also demonstrate a commitment to expertise and continuous improvement. Recent advancements include modular screen designs that allow for easy replacement and maintenance, minimizing downtime. Other innovations involve the incorporation of technology, such as automatic detection systems that alert operators to potential issues before they result in costly repairs. These advancements not only optimize operational efficiency but also align with sustainability efforts by minimizing resource waste and energy consumption. Furthermore, the choice of provider for shaker screens can significantly affect an operation’s success. Providers that stand out in expertise usually offer comprehensive support, from pre-sale consultancy to after-sales service, ensuring the screen's optimal performance throughout its life span. This holistic approach builds a strong sense of trust with clients, encouraging long-term partnerships and steady industrial growth. In conclusion, the importance of industrial shaker screens in processing industries cannot be overstated. Their performance has a direct impact on productivity, operational costs, and the quality of the end product. By understanding the complexities of screen selection, maintenance, and innovation, industries can harness the full potential of this tool. Insights from seasoned experts drive the proper application of shaker screens, guaranteeing that businesses remain competitive while optimizing their processing practices.

Share

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025