- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

mar . 06, 2025 17:45

Back to list

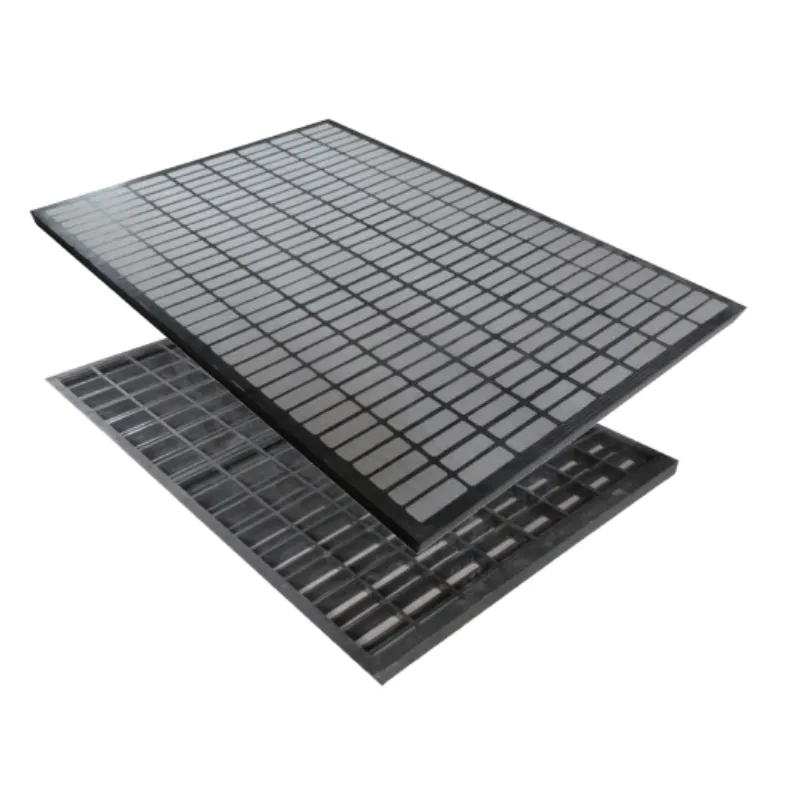

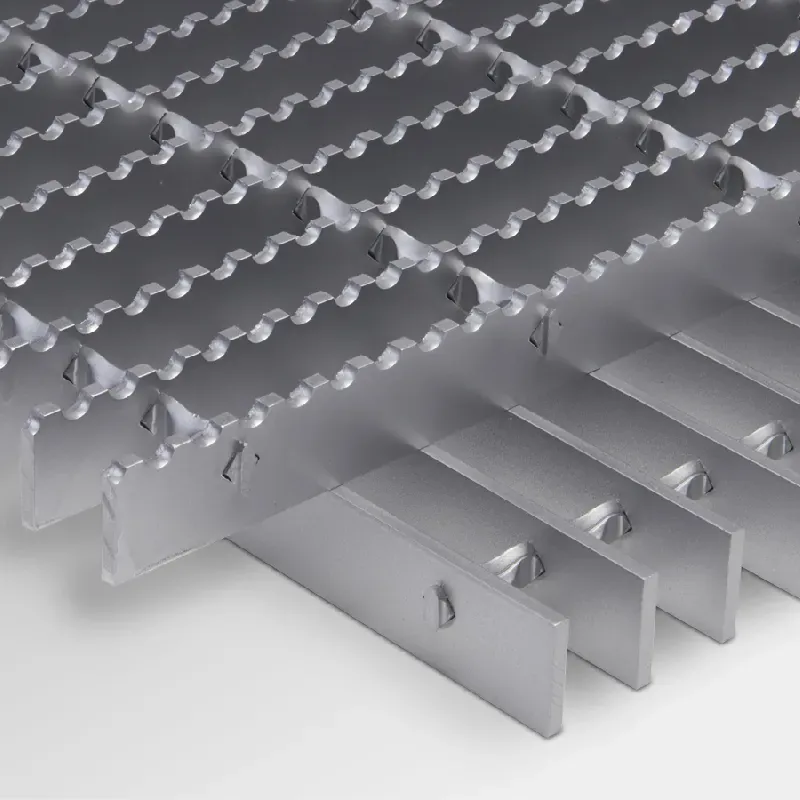

Riveted Grating

Industrial metal grating is a fundamental component in various sectors, offering unmatched strength, durability, and versatility. As industries expand and innovate, the demand for robust and reliable flooring solutions continues to rise. This is where metal grating comes into play, serving as an indispensable resource for safe and efficient industrial operations.

When discussing the expertise within the field of industrial metal grating, it is crucial to note the ongoing research and development endeavors aimed at improving material properties and manufacturing processes. Collaborations between engineers and material scientists have led to innovations such as composite gratings that incorporate fiberglass or resin, which are tailored to environments requiring specific chemical resistances or reduced weights. Authoritativeness in industrial metal grating comes from adherence to strict industry standards and certifications, ensuring that products meet all safety, durability, and environmental guidelines. Reputable manufacturers maintain compliance with international standards like ASTM, ANSI, and ISO, which not only guarantees product integrity but also client trust in the material's dependability over long-term use. Trustworthiness is paramount, and manufacturers often provide extensive testing data, usage warranties, and customer case studies demonstrating the grating's performance in real-world conditions. Client testimonials often highlight the personal experiences of enhanced safety, efficiency, and cost effectiveness after implementing metal grating solutions. In conclusion, industrial metal grating stands as a pillar of modern industry due to its adaptability, reliability, and enduring strength. Experts in the field understand the significant role it plays in creating safe, productive environments and continually seek to offer the highest quality products matched with unparalleled customer support. For industry leaders, selecting the right metal grating involves consulting with trusted manufacturers who provide not just a product, but a partnership dedicated to improving operational efficiencies and above all, worker safety.

When discussing the expertise within the field of industrial metal grating, it is crucial to note the ongoing research and development endeavors aimed at improving material properties and manufacturing processes. Collaborations between engineers and material scientists have led to innovations such as composite gratings that incorporate fiberglass or resin, which are tailored to environments requiring specific chemical resistances or reduced weights. Authoritativeness in industrial metal grating comes from adherence to strict industry standards and certifications, ensuring that products meet all safety, durability, and environmental guidelines. Reputable manufacturers maintain compliance with international standards like ASTM, ANSI, and ISO, which not only guarantees product integrity but also client trust in the material's dependability over long-term use. Trustworthiness is paramount, and manufacturers often provide extensive testing data, usage warranties, and customer case studies demonstrating the grating's performance in real-world conditions. Client testimonials often highlight the personal experiences of enhanced safety, efficiency, and cost effectiveness after implementing metal grating solutions. In conclusion, industrial metal grating stands as a pillar of modern industry due to its adaptability, reliability, and enduring strength. Experts in the field understand the significant role it plays in creating safe, productive environments and continually seek to offer the highest quality products matched with unparalleled customer support. For industry leaders, selecting the right metal grating involves consulting with trusted manufacturers who provide not just a product, but a partnership dedicated to improving operational efficiencies and above all, worker safety.

Share

Prev:

Next:

Latest news

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025