- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

feb . 14, 2025 05:58

Back to list

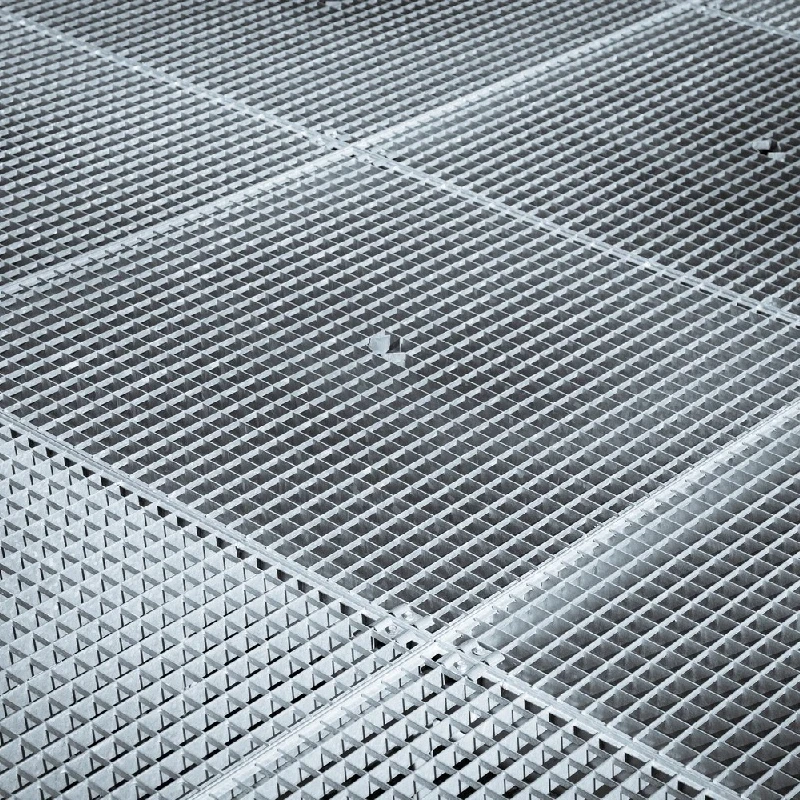

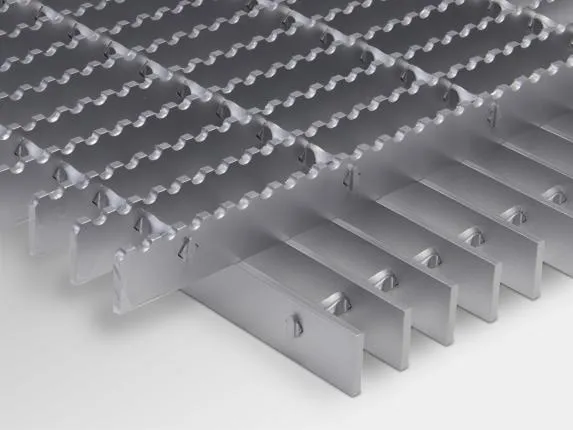

steel walkway grating

Steel grating, a vital component in a plethora of industrial applications, offers a unique combination of strength, safety, and cost-effectiveness. For engineers, architects, and construction professionals looking to utilize this material, understanding the intricacies of steel grating products is paramount to maximizing their benefits in structural and industrial projects. This exploration dives into the particulars of steel grating, underscoring its real-world applications and the facts that underpin its long-standing favor in construction and industrial settings.

The environment also benefits from steel grating. Many manufacturers now produce grating from recycled materials, which minimizes environmental impact. Furthermore, steel grating's long service life means less frequent replacement, reducing resource waste and promoting sustainability in construction practices. From an expertise standpoint, customizing steel grating to fit specific applications enhances its versatility. Manufacturers provide various options, including variable spacing, different load capacities, and surface treatments like galvanizing for enhanced corrosion resistance. This adaptability ensures that industries can source a grating product that impeccably suits their specific requirements, providing custom solutions without a compromise on quality or performance. Authoritativeness in steel grating comes from its proven reliability across diverse sectors. Case studies abound, showcasing successful long-term applications in shipyards, power plants, waste treatment facilities, and beyond. These real-world successes cement steel grating’s reputation as a robust choice for demanding conditions. The trustworthiness of steel grating is further substantiated by rigorous industry standards and certifications. Compliance with international safety and quality standards, such as the American Welding Society (AWS) and ISO certifications, guarantees that the products meet stringent criteria for performance, safety, and durability. In summary, steel grating stands out as a product that adheres to the core principles of reliability and efficiency, delivering unmatched performance in both industrial and architectural applications. Its capacity to adapt to different functional and aesthetic needs, combined with its economic and ecological efficiencies, makes it an indispensable material. As industries continue to evolve, steel grating remains at the forefront, a testament to its enduring legacy in engineering and construction domains.

The environment also benefits from steel grating. Many manufacturers now produce grating from recycled materials, which minimizes environmental impact. Furthermore, steel grating's long service life means less frequent replacement, reducing resource waste and promoting sustainability in construction practices. From an expertise standpoint, customizing steel grating to fit specific applications enhances its versatility. Manufacturers provide various options, including variable spacing, different load capacities, and surface treatments like galvanizing for enhanced corrosion resistance. This adaptability ensures that industries can source a grating product that impeccably suits their specific requirements, providing custom solutions without a compromise on quality or performance. Authoritativeness in steel grating comes from its proven reliability across diverse sectors. Case studies abound, showcasing successful long-term applications in shipyards, power plants, waste treatment facilities, and beyond. These real-world successes cement steel grating’s reputation as a robust choice for demanding conditions. The trustworthiness of steel grating is further substantiated by rigorous industry standards and certifications. Compliance with international safety and quality standards, such as the American Welding Society (AWS) and ISO certifications, guarantees that the products meet stringent criteria for performance, safety, and durability. In summary, steel grating stands out as a product that adheres to the core principles of reliability and efficiency, delivering unmatched performance in both industrial and architectural applications. Its capacity to adapt to different functional and aesthetic needs, combined with its economic and ecological efficiencies, makes it an indispensable material. As industries continue to evolve, steel grating remains at the forefront, a testament to its enduring legacy in engineering and construction domains.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025