- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Ion . 19, 2025 00:41

Back to list

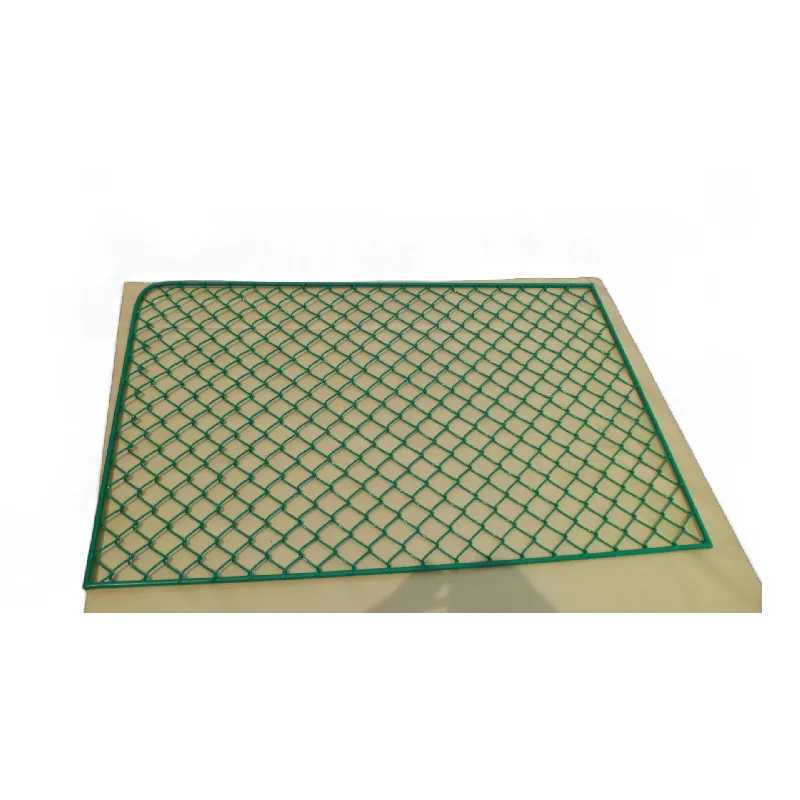

steel grating cost per square foot

Understanding the cost dynamics of steel grating per square foot is pivotal for construction professionals, architects, and procurement experts dealing with materials for diverse applications. Steel grating, characterized by its durability, strength, and versatility, is a preferred choice in numerous industries, from industrial flooring systems to safety platforms and drainage covers. Let's delve into the factors affecting the cost and how an expert in the field evaluates these variables for optimized procurement.

5. Market Conditions Like many commodities, steel prices fluctuate based on global economic conditions, demand in sectors such as construction or automotive, and geopolitical factors affecting raw material supply. Professionals track these trends to forecast potential price shifts and adjust budgets or project timing accordingly. 6. Supplier and Volume Discounts The supplier’s reputation and location can affect pricing. Long-standing relationships with reputable suppliers often yield benefits like discounts or favorable terms. Additionally, purchasing in large volumes can secure better rates due to economies of scale. Expertise in procurement involves comprehensive market analysis and informed decision-making. Access to up-to-date material costs, supplier networks, and market forecasts enhances budgeting accuracy. Transparent and ethical sourcing practices, prioritizing both cost-effectiveness and sustainability, bolster trustworthiness and authority in the field. Managing the steel grating budget is a balancing act of experience and expertise. Decision-makers must integrate technical requirements with fiscal prudence to achieve the best results for their specific application. Utilizing industry-standard benchmarks and cost estimation tools, professionals optimize project specifications, thereby maximizing value without compromising on quality or safety standards. Ultimately, navigating the cost of steel grating per square foot requires a strategic approach that respects the dynamic nature of material costs, supports the application’s functional requirements, and aligns with an organization's financial objectives.

5. Market Conditions Like many commodities, steel prices fluctuate based on global economic conditions, demand in sectors such as construction or automotive, and geopolitical factors affecting raw material supply. Professionals track these trends to forecast potential price shifts and adjust budgets or project timing accordingly. 6. Supplier and Volume Discounts The supplier’s reputation and location can affect pricing. Long-standing relationships with reputable suppliers often yield benefits like discounts or favorable terms. Additionally, purchasing in large volumes can secure better rates due to economies of scale. Expertise in procurement involves comprehensive market analysis and informed decision-making. Access to up-to-date material costs, supplier networks, and market forecasts enhances budgeting accuracy. Transparent and ethical sourcing practices, prioritizing both cost-effectiveness and sustainability, bolster trustworthiness and authority in the field. Managing the steel grating budget is a balancing act of experience and expertise. Decision-makers must integrate technical requirements with fiscal prudence to achieve the best results for their specific application. Utilizing industry-standard benchmarks and cost estimation tools, professionals optimize project specifications, thereby maximizing value without compromising on quality or safety standards. Ultimately, navigating the cost of steel grating per square foot requires a strategic approach that respects the dynamic nature of material costs, supports the application’s functional requirements, and aligns with an organization's financial objectives.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025