- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

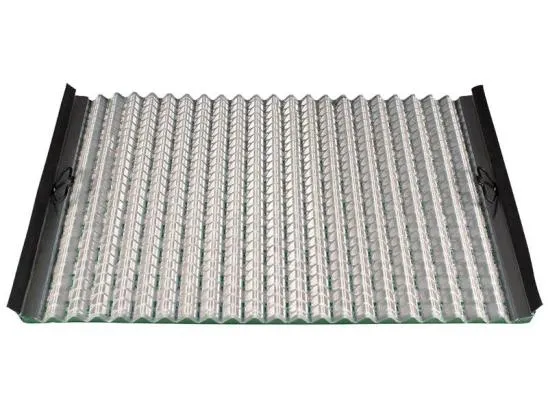

Serrated Bar Grating Design for Enhanced Drainage and Structural Support Applications

Understanding Serrated Bar Grating Applications and Advantages

Serrated bar grating, also known as serrated steel grating or serrated metal grating, is a type of walkway support often employed in industrial and commercial settings. It is characterized by its unique serrated surface, which provides enhanced traction and safety for personnel working in various environments. This article delves into the features, applications, and benefits of serrated bar grating, illustrating why it is a popular choice in many industries.

Features of Serrated Bar Grating

Serrated bar grating is typically made from steel, aluminum, or fiberglass and consists of a series of parallel bars with a specifically designed serration pattern on the surface. The notched or serrated design creates a slip-resistant surface, significantly reducing the risk of falls, particularly in wet or oily conditions. The spacing between the bars also allows for efficient drainage of liquids, making it ideal for environments prone to spills.

The standard configuration of serrated bar grating involves load-bearing bars that support the weight of personnel and equipment, while the serrated surface enhances grip. This type of grating is usually produced in standard sizes and can be customized to meet specific project requirements. It is available in various thicknesses and heights, offering flexibility in design and application.

Applications of Serrated Bar Grating

Given its robust design and safety features, serrated bar grating is widely used across various industries

1. Industrial Facilities Factories and manufacturing plants frequently utilize serrated bar grating for walkways, platforms, and assembly lines. Its slip-resistant surface is critical in preventing workplace accidents.

2. Commercial Buildings Serrated bar grating serves as effective flooring for commercial properties, including shopping centers and office buildings. It provides a durable surface that can withstand heavy foot traffic.

3. Food Processing In food and beverage industries, the grating’s water drainage capabilities are essential for maintaining hygiene. Its easy cleaning and corrosion-resistant materials make it suitable for areas susceptible to spills.

serrated bar grating

5. Transportation Serrated bar grating is also found in transit applications, such as bridges and walkways in rail stations, where safety and durability are paramount.

Benefits of Serrated Bar Grating

The popularity of serrated bar grating is attributable to its numerous advantages

1. Enhanced Safety With its slip-resistant surface, it minimizes the risk of accidents in high-traffic areas, providing a safer environment for workers.

2. Durability Made from robust materials, serrated bar grating can withstand harsh conditions, including extreme temperatures and corrosive environments.

3. Easy Installation The modular nature of this grating allows for straightforward installation and modification, making it a convenient choice for contractors.

4. Cost-Effective While initial costs may vary, the long lifespan and minimal maintenance requirements can lead to significant savings in the long run.

5. Aesthetic Versatility Available in different finishes and colors, serrated bar grating can be designed to blend into various architectural styles while maintaining functionality.

In conclusion, serrated bar grating is an indispensable material in modern engineering and construction, enhancing safety and functionality across a variety of settings. Its traction and durability combined with its versatility make it a wise choice for anyone looking to ensure safety and efficiency in their facilities. As industries continue to grow and evolve, serrated bar grating will undoubtedly remain a key component in developing safe working environments.

-

Welded Steel Grating: The Strong Foundation for Industrial SafetyNewsJul.16,2025

-

Strong and Safe: Swaged Grating SolutionsNewsJul.16,2025

-

Smart Choice For Industrial Safety MeshNewsJul.16,2025

-

Press-Locked Steel Grating: The Ultimate in Strength and SafetyNewsJul.16,2025

-

Keep Worksites Safer With Practical NettingNewsJul.16,2025

-

Helideck Safety Nets: Your First Line of DefenseNewsJul.16,2025