- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Chw . 15, 2025 04:03

Back to list

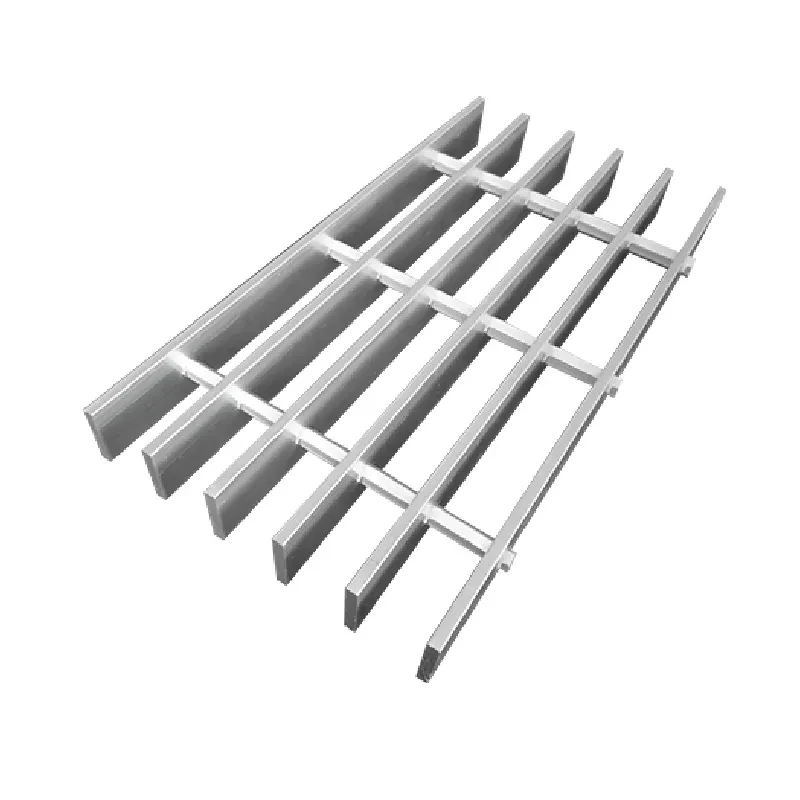

steel walkway grating

In the industrial sector, platform grating is an essential component, offering a versatile and reliable solution for flooring, decking, and other structural applications. Understanding the specifications of platform grating is vital for ensuring the safety, durability, and efficiency of the structures in which they are employed. This article delves into the critical aspects of platform grating specifications, offering insights from industry experts and real-world applications to establish a comprehensive guide that embodies expertise, authority, trustworthiness, and a wealth of experience.

Industry standards, such as those from OSHA or ASTM, guide the design and use of platform grating. These standards establish minimum load ratings, guaranteeing that the grating can withstand specified static and dynamic forces. Understanding and complying with these standards is crucial, as it directly impacts legal compliance and safety assurance. Surface Treatment and Finishes Surface treatment enhances the longevity and safety of platform grating. Options include galvanization, painting, and anodizing, each serving a particular protective role against rust, chemical exposure, and wear and tear. Anti-slip coatings or serrated surfaces are also vital, especially in areas subject to wet or oily conditions. The right finish not only extends the lifespan of the grating but also ensures the safety of those who use it. Case Studies and Real-World Insights Numerous industries have shared their experiences, accentuating the importance of proper specification. In the petrochemical sector, grating specifications were tailored to withstand corrosive environments, thereby significantly reducing maintenance costs and enhancing worker safety over prolonged usage. In contrast, the automotive industry focused on load-bearing specifications to support heavy machinery without compromising the ease of transport and installation, showcasing the grating's adaptability. Conclusion The precise specification of platform grating is critical to the success and safety of numerous industrial applications. A well-informed choice regarding materials, mesh configurations, load ratings, and surface finishes will not only satisfy immediate functional requirements but also ensure long-term sustainability and compliance with industry standards. This article draws from expertise across multiple sectors, underscoring the importance of trustworthiness and authority in specifying platform grating that truly meets the bespoke needs of each application.

Industry standards, such as those from OSHA or ASTM, guide the design and use of platform grating. These standards establish minimum load ratings, guaranteeing that the grating can withstand specified static and dynamic forces. Understanding and complying with these standards is crucial, as it directly impacts legal compliance and safety assurance. Surface Treatment and Finishes Surface treatment enhances the longevity and safety of platform grating. Options include galvanization, painting, and anodizing, each serving a particular protective role against rust, chemical exposure, and wear and tear. Anti-slip coatings or serrated surfaces are also vital, especially in areas subject to wet or oily conditions. The right finish not only extends the lifespan of the grating but also ensures the safety of those who use it. Case Studies and Real-World Insights Numerous industries have shared their experiences, accentuating the importance of proper specification. In the petrochemical sector, grating specifications were tailored to withstand corrosive environments, thereby significantly reducing maintenance costs and enhancing worker safety over prolonged usage. In contrast, the automotive industry focused on load-bearing specifications to support heavy machinery without compromising the ease of transport and installation, showcasing the grating's adaptability. Conclusion The precise specification of platform grating is critical to the success and safety of numerous industrial applications. A well-informed choice regarding materials, mesh configurations, load ratings, and surface finishes will not only satisfy immediate functional requirements but also ensure long-term sustainability and compliance with industry standards. This article draws from expertise across multiple sectors, underscoring the importance of trustworthiness and authority in specifying platform grating that truly meets the bespoke needs of each application.

Share

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025