- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

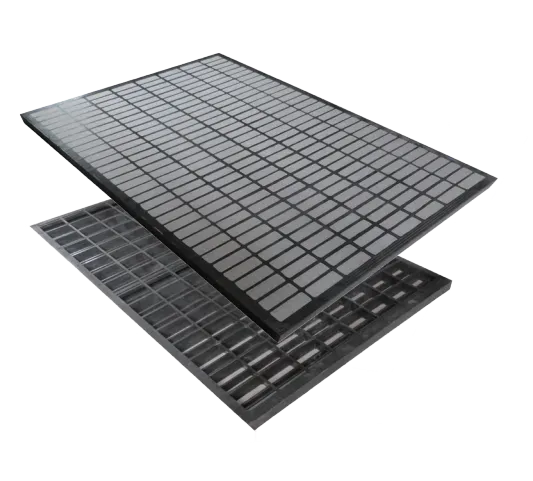

galvanised floor grating

Understanding Galvanised Floor Grating Features, Benefits, and Applications

Galvanised floor grating is an essential material widely used across various industries and applications. Its robust nature, combined with its corrosion resistance, makes it a popular choice in environments where strength and durability are critical. This article delves into the features, benefits, and typical applications of galvanised floor grating, providing a comprehensive overview of why it is favored in many industrial settings.

What is Galvanised Floor Grating?

Galvanised floor grating refers to a type of flooring made from steel that has been coated with a layer of zinc through a process known as galvanisation. This coating prevents rust and extends the lifespan of the metal, making it suitable for use in challenging environments. The grating consists of a series of parallel bars, which can be manufactured in different shapes and sizes, depending on the specific requirements of the project. It is typically available in two types steel grating and aluminum grating, with the former being more common in heavy-duty applications.

Features of Galvanised Floor Grating

1. Corrosion Resistance The galvanisation process ensures that the steel is protected from moisture, chemicals, and other corrosive substances. This feature is particularly important when the grating is used in outdoor environments or in facilities where chemicals are present.

2. Load-Bearing Capacity Galvanised floor grating is designed to support heavy loads, which makes it ideal for industrial applications. It can bear significant weight, making it suitable for use in warehouses, factories, and commercial buildings.

3. Reduced Weight Compared to solid flooring materials, galvanised grating is lightweight, which simplifies installation and reduces transportation costs. Despite its lighter nature, it does not compromise on strength.

4. Slip Resistance Many galvanised gratings come with a slip-resistant surface, enhancing safety by reducing the likelihood of slips and falls, especially in wet or oily conditions.

5. Ease of Maintenance The smooth surface of galvanised grating is easy to clean and does not accumulate dirt or debris easily, making maintenance a straightforward task.

Benefits of Using Galvanised Floor Grating

galvanised floor grating

- Cost-Effectiveness While the initial investment might be higher than some alternatives, the long lifespan of galvanised grating due to its corrosion resistance and low maintenance needs makes it a cost-effective choice in the long run.

- Versatility Galvanised floor grating can be used in various applications, from pedestrian walkways to heavy machinery platforms, making it a versatile option for different industries

.- Aesthetic Appeal The clean, industrial look of galvanised grating complements modern architecture, making it suitable for both functional and aesthetic purposes.

- Environmental Impact Steel is a recyclable material, and choosing galvanised steel grating contributes to environmental sustainability by reducing waste and promoting recycling efforts.

Applications of Galvanised Floor Grating

Galvanised floor grating finds its use in numerous sectors, including

- Industrial Sector Commonly used in factories, power plants, and chemical processing facilities, where it serves as flooring, walkways, and platforms.

- Commercial Buildings Frequently employed in shopping centers, airports, and commercial kitchens, providing safe and durable surfaces for high foot traffic.

- Marine Applications Ideal for shipyards, docks, and offshore platforms due to its corrosion resistance against saltwater.

- Municipal Infrastructures Used in wastewater treatment facilities and stormwater management systems, where high corrosion resistance is required.

In conclusion, galvanised floor grating is a versatile and durable solution for various flooring needs across different sectors. Its combination of strength, corrosion resistance, and slip safety makes it a preferred choice for environments that demand resilience and reliability. As industries continue to prioritize safety, sustainability, and cost-effectiveness, the demand for galvanised floor grating is expected to grow, solidifying its place as an indispensable material in modern construction and manufacturing.

-

Welded Steel Grating: The Strong Foundation for Industrial SafetyNewsJul.16,2025

-

Strong and Safe: Swaged Grating SolutionsNewsJul.16,2025

-

Smart Choice For Industrial Safety MeshNewsJul.16,2025

-

Press-Locked Steel Grating: The Ultimate in Strength and SafetyNewsJul.16,2025

-

Keep Worksites Safer With Practical NettingNewsJul.16,2025

-

Helideck Safety Nets: Your First Line of DefenseNewsJul.16,2025