- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Shale Shaker Screen-Anping County Hangshun Wire Mesh Manufacture Co., Ltd|Efficient Solid Control&Drilling Fluid Management

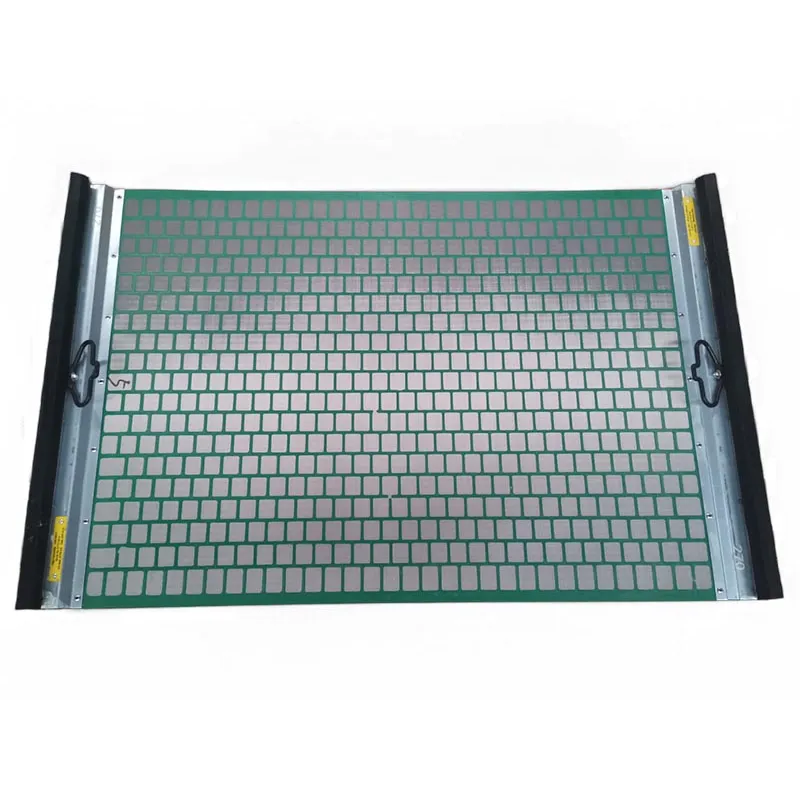

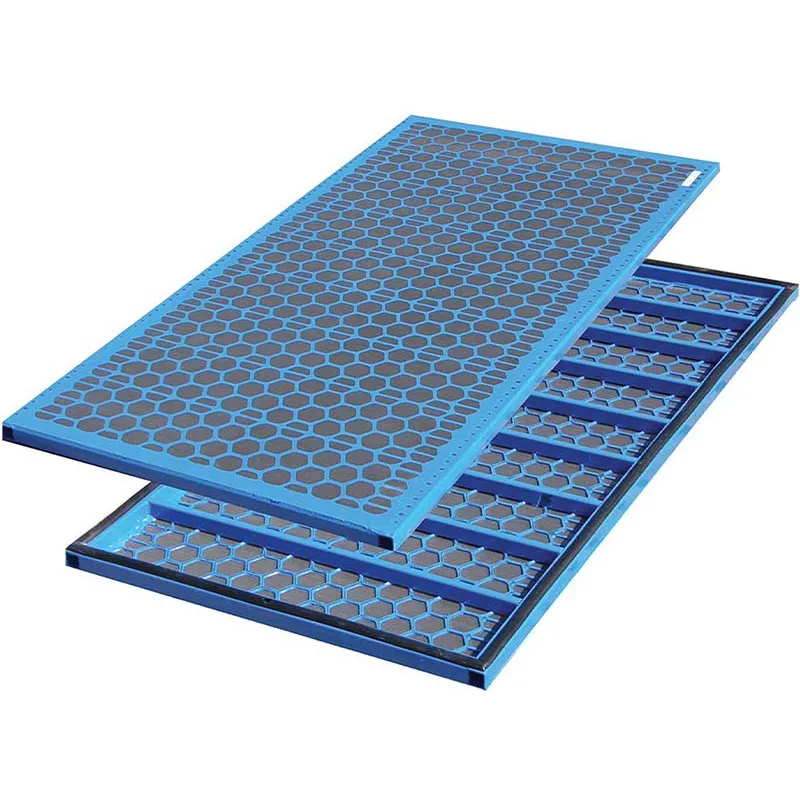

Shale Shaker Screen: Efficient Solid Control for Oil & Gas Industry

As a leading manufacturer in the oil and gas industry, Anping County Hangshun Wire Mesh Manufacture Co., Ltd offers high-quality Shale Shaker Screen solutions designed to optimize drilling fluid management. Our products are engineered to meet the demanding requirements of modern petroleum operations, ensuring efficient solid control and extended equipment lifespan.

Core Functionality and Technical Specifications

The Shale Shaker Screen is a critical component in drilling fluid solid control systems, designed to separate cuttings and other solid particles from the drilling fluid. Our screens are manufactured using advanced technologies, featuring:

- High-strength stainless steel or polyurethane mesh for exceptional durability

- Customizable mesh aperture sizes (ranging from 20 to 400 mesh)

- Corrosion-resistant coating for harsh operating environments

- Optimized vibration system design for improved separation efficiency

Key Advantages for Industrial Applications

Our Shale Shaker Screens offer significant benefits for oil and gas operations:

- Enhanced Performance: Advanced mesh technology ensures efficient solid-liquid separation, reducing maintenance costs by up to 40%

- Longer Lifespan: High-quality materials resist wear and tear, extending screen life by 30% compared to standard products

- Customization: Available in various configurations to match different drilling equipment specifications

- Cost Efficiency: Reduces drilling fluid waste and lowers operational expenses through improved recycling capabilities

Industry Applications and Market Demand

Shale Shaker Screens are essential in:

- Onshore/offshore drilling operations

- Oilfield mud recycling systems

- Geothermal energy exploration

- Mineral processing plants

The global demand for efficient solid control systems has driven innovation in this sector. Our products address common industry challenges such as:

- Screen blinding caused by fine particles

- High maintenance frequency due to material degradation

- Inconsistent separation efficiency in varying operating conditions

Company Expertise and Technological Innovation

With over 15 years of experience in wire mesh manufacturing, Anping County Hangshun Wire Mesh Manufacture Co., Ltd has established itself as a reliable supplier in the petroleum industry. Our key strengths include:

- ISO 9001-certified production processes

- Dedicated R&D team with 20+ patents in screening technology

- State-of-the-art manufacturing facilities with CNC precision equipment

- Comprehensive quality control system from raw material selection to final inspection

Proven Performance and Customer Testimonials

Our Shale Shaker Screens have been successfully deployed in numerous projects worldwide, including:

- Shale gas extraction operations in the Permian Basin

- Deepwater drilling projects in the Gulf of Mexico

- Coalbed methane development in China's Sichuan Basin

Customer feedback highlights:

"The improved screen life and separation efficiency have significantly reduced our operational downtime." - John M., Drilling Operations Manager at XYZ Energy

"Our maintenance costs decreased by 35% after switching to Hangshun's screens." - Maria S., Production Supervisor at ABC Oilfield Services

Implementation and Customization Solutions

We offer tailored solutions to meet specific client requirements:

- Screen size customization (standard: 48" x 96", 60" x 108")

- Material selection based on drilling fluid composition

- Installation support from our technical team

- Regular maintenance and replacement services

Safety and Environmental Compliance

All our products meet international safety standards and environmental regulations, including:

- OSHA compliance for industrial equipment

- RoHS directive for hazardous substance restrictions

- CE certification for European market access

Our manufacturing processes prioritize environmental protection through:

- Energy-efficient production methods

- Recycling programs for production waste

- Low-emission coating technologies

Packaging and Logistics Solutions

We provide:

- Customized packaging for bulk orders (standard: 50-100 pieces per pallet)

- International shipping services with tracking capabilities

- Compliance with UN packaging regulations for hazardous materials

Comprehensive Customer Support

Our commitment to customer satisfaction includes:

- 24/7 technical support via phone and online chat

- On-site installation and training services

- Warranty coverage for 12-24 months depending on product model

- Regular product updates and maintenance schedules

Contact Us for Custom Solutions

For detailed specifications or customized quotes, please visit our official website at www.hfpetromesh.com or contact us directly:

- Phone: +86-312-6789012

- Email: sales@hfpetromesh.com

- Address: No. 88, Industrial Zone, Anping County, Hebei Province, China

Frequently Asked Questions

Q: What is the typical lifespan of your Shale Shaker Screens?

A: Under normal operating conditions, our screens can last between 6-12 months, depending on the drilling fluid composition and operational intensity.

Q: Can you provide samples for testing?

A: Yes, we offer sample testing services to help clients evaluate performance before placing bulk orders.

Q: What is the minimum order quantity?

A: The standard MOQ is 10 sets, but we can accommodate smaller orders for special requirements.

Q: Do you offer installation support?

A: Our technical team can provide on-site installation guidance and training upon request.

Conclusion

Choosing Anping County Hangshun Wire Mesh Manufacture Co., Ltd for your Shale Shaker Screen needs ensures access to high-quality, durable solutions that enhance drilling efficiency and reduce operational costs. Visit our website to explore our full product range and experience our commitment to excellence.

-

Upgrade Your Industrial Operations with Durable Steel GratingNewsJul.21,2025

-

Transform Your Flooring Solutions with Quality Floor GratingNewsJul.21,2025

-

Top-Quality Shale Shaker Screens for Your Drilling NeedsNewsJul.21,2025

-

High-Quality Steel Grating for All Your Industrial NeedsNewsJul.21,2025

-

Explore the Durability and Versatility of Galvanized Steel GratingNewsJul.21,2025

-

Ensure Maximum Safety with Premium Safety NetsNewsJul.21,2025