- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

High-Quality Shaker Screens Available for Purchase at Competitive Prices

Shaker Screens for Sale A Comprehensive Guide

Shaker screens are essential components in various industries, particularly in oil and gas drilling operations, mining, and construction. These critical tools help separate materials by size and ensure that the desired product is obtained at an optimal cost. For those looking to purchase shaker screens, understanding their types, applications, and the factors to consider when making a buying decision is crucial.

What Are Shaker Screens?

Shaker screens, commonly referred to as screen meshes or shaker trays, are mechanical devices used to separate particles of different sizes. They are typically made from various materials, including wire mesh, polyurethane, and rubber. Each type has its unique advantages, making them suitable for different applications. The screens are mounted on shaker units, which vibrate to facilitate the separation process.

Types of Shaker Screens

Shaker screens come in several types, each designed to meet specific operational requirements

1. Wire Mesh Screens These are the most common type, known for their strength and durability. They are suitable for various materials, including sands, gravel, and other aggregates. Wire mesh screens provide excellent performance in separation tasks due to their ability to withstand high temperatures and mechanical stress.

2. Polyurethane Screens These screens are manufactured from a flexible and robust material that allows them to withstand wear and tear without compromising efficiency. They are particularly effective in applications involving slurries and are known for their ability to reduce blinding and pegging.

3. Rubber Screens Rubber screens are ideal for applications requiring high flexibility and resilience against impact. They are often used in mining and mineral processing operations, where heavy materials need to be screened.

Applications of Shaker Screens

Shaker screens are utilized in various industries, including

shaker screen for sale

- Oil and Gas In drilling operations, shaker screens are crucial for separating drilling mud from cuttings

. Proper separation extends the life of drilling fluids and ensures efficient operation.- Mining Shaker screens are used to grade and separate minerals and ores by size. They play a critical role in the processing of materials, ensuring that only the desired sizes proceed to the next stage of processing.

- Construction In construction, shaker screens help separate aggregates for concrete production and other applications. They ensure that materials meet specific size specifications for quality control.

Factors to Consider When Buying Shaker Screens

When looking for shaker screens for sale, several factors should influence your decision

1. Material Compatibility Ensure that the type of shaker screen you purchase is compatible with the materials you intend to process. Different materials may require specific screen types for optimal performance.

2. Screen Size and Mesh The size of the shaker screen and the mesh size are crucial in determining the separation efficiency. Ensure you select the right dimensions and mesh openings for your operational needs.

3. Durability and Maintenance Consider the durability of the materials used in the screen's construction. A more robust screen may require less frequent replacement, ultimately lowering costs. Additionally, consider maintenance requirements and ease of cleaning.

4. Supplier Reputation Research potential suppliers of shaker screens. A reputable supplier offers quality products, excellent customer service, and technical support, ensuring you have the necessary resources for a successful operation.

Conclusion

Shaker screens are indispensable in various industries, providing effective material separation and contributing to operational efficiency. When considering purchasing shaker screens for sale, take the time to understand your specific needs, explore the different types available, and evaluate suppliers carefully. With the right shaker screens, you can enhance your operational capabilities, improve material quality, and achieve greater overall efficiency in your processes. Investing in the right equipment will yield long-term benefits and ensure your operations run smoothly.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

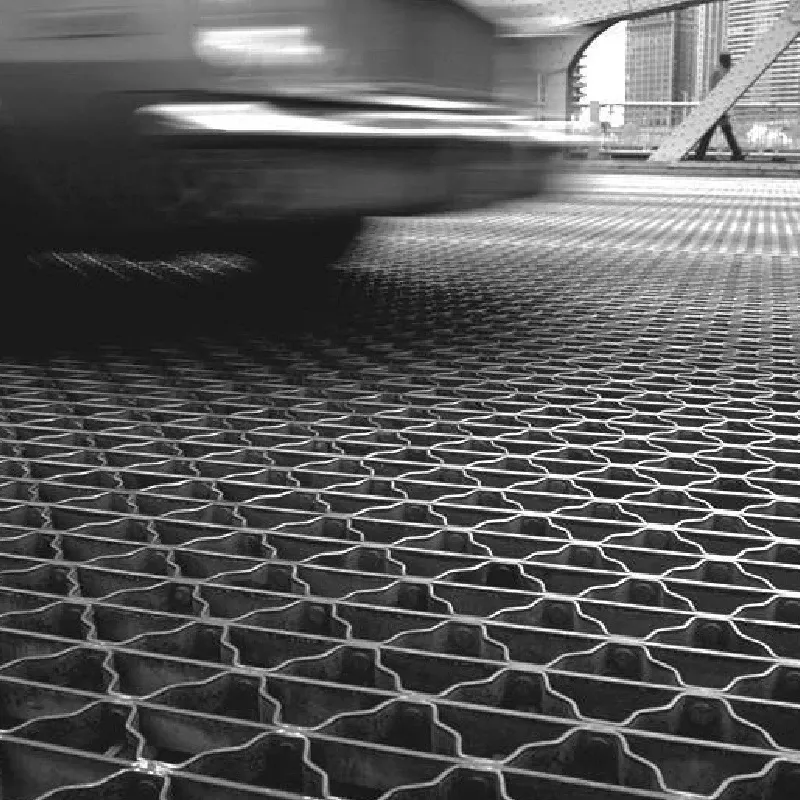

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025