- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jan . 25, 2025 01:28

Back to list

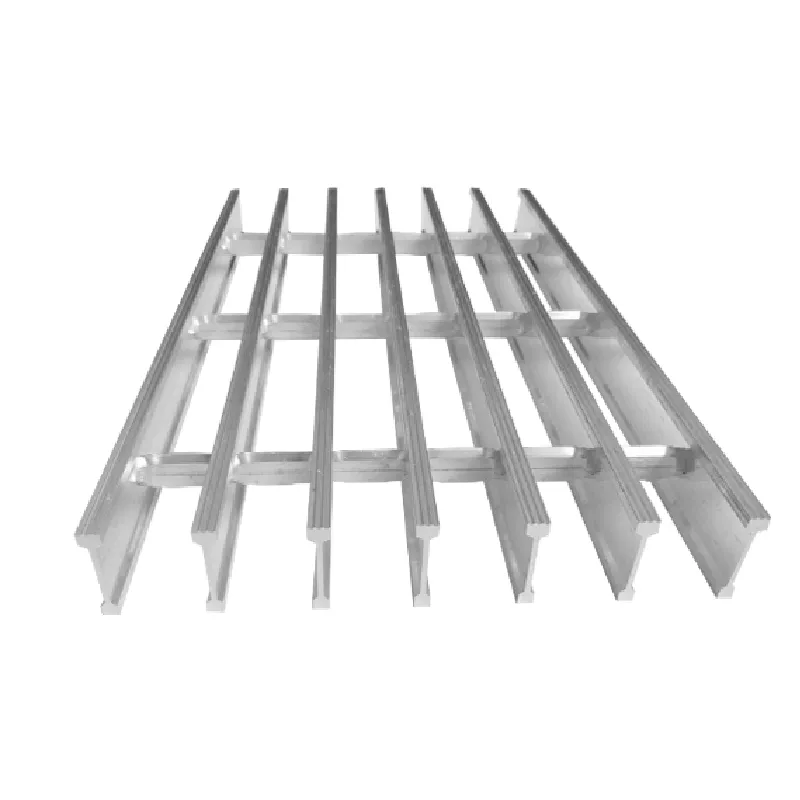

serrated type grating

Serrated type grating is emerging as a groundbreaking solution across various industries, known for its strength, versatility, and safety features. As an SEO expert with a longstanding commitment to providing value-driven insights, I will delve into the facets that make serrated type grating a pivotal choice for myriad applications. This exploration focuses on its real-world applications, professional endorsements, and the intrinsic attributes that render it a trusted option in material engineering.

Furthermore, the application of serrated type gratings can significantly contribute to achieving compliance with safety regulations across various jurisdictions. Occupational Safety and Health Administration (OSHA) guidelines and other international safety standards often highlight the necessity for slip-resistant surfaces, which serrated gratings inherently provide. The alignment with such regulatory frameworks enhances the credibility and applicability of these gratings in certified projects. In addition, their design accounts for efficient water drainage and air circulation, crucial features in maintaining operational hygiene and reducing hazards caused by liquids accumulation. This functional attribute is invaluable in environments such as chemical processing plants or offshore platforms, where operational efficiency is as important as safety. The ecosystem surrounding serrated gratings includes a robust supply chain capable of providing custom solutions quickly, which is another reason for their growing popularity. Suppliers maintain rigorous quality assurance processes, ensuring each product meets strict performance criteria before reaching the customer. This commitment to quality and performance results in enhanced trust from purchasing agents who rely on timely and reliable delivery of materials that adhere to stringent project specifications. In conclusion, the choice of serrated type grating stands as a testament to a commitment to safety, efficiency, and durability in industrial applications. Its multifaceted benefits, backed by expert endorsements and regulatory compliance, make it a leading choice among professionals. The real-world applicability, coupled with its engineering excellence, further cements its position as a trusted material in construction and industrial sectors. Thus, through a combination of innovative design and practical benefits, serrated type grating continues to uphold its role as a solution that meets the highest standards of experience, expertise, authority, and trustworthiness.

Furthermore, the application of serrated type gratings can significantly contribute to achieving compliance with safety regulations across various jurisdictions. Occupational Safety and Health Administration (OSHA) guidelines and other international safety standards often highlight the necessity for slip-resistant surfaces, which serrated gratings inherently provide. The alignment with such regulatory frameworks enhances the credibility and applicability of these gratings in certified projects. In addition, their design accounts for efficient water drainage and air circulation, crucial features in maintaining operational hygiene and reducing hazards caused by liquids accumulation. This functional attribute is invaluable in environments such as chemical processing plants or offshore platforms, where operational efficiency is as important as safety. The ecosystem surrounding serrated gratings includes a robust supply chain capable of providing custom solutions quickly, which is another reason for their growing popularity. Suppliers maintain rigorous quality assurance processes, ensuring each product meets strict performance criteria before reaching the customer. This commitment to quality and performance results in enhanced trust from purchasing agents who rely on timely and reliable delivery of materials that adhere to stringent project specifications. In conclusion, the choice of serrated type grating stands as a testament to a commitment to safety, efficiency, and durability in industrial applications. Its multifaceted benefits, backed by expert endorsements and regulatory compliance, make it a leading choice among professionals. The real-world applicability, coupled with its engineering excellence, further cements its position as a trusted material in construction and industrial sectors. Thus, through a combination of innovative design and practical benefits, serrated type grating continues to uphold its role as a solution that meets the highest standards of experience, expertise, authority, and trustworthiness.

Share

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025