- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

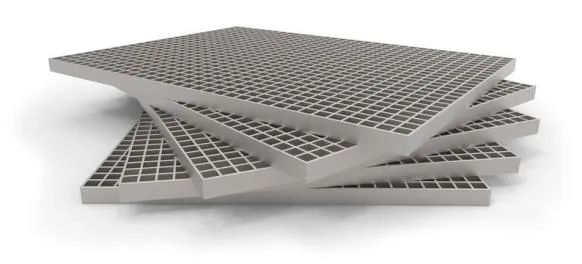

pipeline reinforced mesh

The Role of Pipeline Reinforced Mesh in Modern Infrastructure

In the realm of modern infrastructure, the strengthening of pipelines is crucial for ensuring security and longevity. One innovative solution that has gained significant attention is the use of pipeline reinforced mesh. This technology not only enhances the structural integrity of pipelines but also addresses various environmental and operational challenges associated with fluid transport systems.

Understanding Pipeline Reinforced Mesh

Pipeline reinforced mesh is a specialized framework designed to provide additional support to pipelines, particularly those that transport liquids or gases under varying pressure conditions. This mesh typically consists of high-strength materials such as steel or composite fibers, intricately woven to form a robust grid that can be layered over existing pipeline structures. The mesh serves multiple critical functions, including increasing resistance to external forces, preventing deformation, and minimizing the risk of leakage.

Advantages of Using Reinforced Mesh

1. Enhanced Structural Integrity One of the primary advantages of pipeline reinforced mesh is its ability to enhance the structural integrity of pipelines. By distributing stress evenly across the surface, the mesh helps to prevent failures that could arise from internal pressure fluctuations or external impacts, such as ground movements or vehicular loads.

2. Corrosion Resistance Corrosion is a leading cause of pipeline deterioration. The integration of reinforced mesh can provide an additional layer of protection against environmental factors that lead to corrosion, such as moisture and chemical exposure. Some modern meshes come with corrosion-resistant coatings, further extending the lifespan of the pipeline.

3. Cost-Effectiveness While the initial investment in reinforced mesh might be higher than traditional reinforcement methods, long-term savings are significant. By reducing the frequency of maintenance and potential replacements, pipeline operators can enjoy lower operational costs over time. Moreover, the increased durability of the pipeline translates to fewer disruptions in service, which is crucial for industries that depend on continuous fluid transport.

pipeline reinforced mesh

4. Ease of Installation Pipeline reinforced mesh can be easily integrated into existing systems. Its lightweight nature and flexibility allow for straightforward application without the need for extensive modifications to the pipeline infrastructure. This ease of installation contributes to quicker project turnaround times and minimizes downtime.

5. Environmental Impact In a world increasingly concerned with sustainability, using pipeline reinforced mesh can also reduce the environmental footprint of pipeline projects. By extending the life of pipelines and reducing leaks, these systems contribute to fewer environmental hazards. This is particularly significant in areas where pipelines traverse sensitive ecosystems.

Applications in Various Industries

The versatility of pipeline reinforced mesh opens doors to numerous applications across different industries. In the oil and gas sector, for instance, pipelines often face high pressures and harsh environmental conditions, making robust reinforcement essential. Similarly, in water supply systems, reinforced mesh can help prevent leaks that could lead to significant resource loss or contamination.

Other industries, such as mining and construction, can benefit from this technology as well. Reinforced mesh can be used to support pipelines responsible for transporting slurries or other viscous materials, where additional strength is paramount to prevent breaks and enhance operational efficiency.

Future Trends

As technological advancements continue to evolve, the future of pipeline reinforced mesh looks promising. Innovations in materials science may lead to even more durable and lightweight options, potentially incorporating smart technologies that can monitor the health of the pipeline in real-time. This could enable rapid response to any emerging issues, further enhancing safety and operational efficiency.

In conclusion, pipeline reinforced mesh represents a significant stride forward in the quest for safer, more efficient infrastructure. Its benefits in terms of structural integrity, cost-effectiveness, and environmental protection position it as a vital component in modern pipeline engineering. As industries continue to face the dual challenge of maintaining efficiency and sustainability, the adoption of reinforced mesh technology will likely become increasingly prevalent, paving the way for resilient and long-lasting infrastructure solutions.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025