- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

CWC Pipe Coating Solutions Durable Concrete Weight Coating for Pipelines

- Introduction to CWC Pipe Coating Solutions

- Technical Advantages in Corrosion Resistance

- Market Comparison: Leading CWC Coating Providers

- Customized Solutions for Diverse Project Needs

- Case Study: Offshore Pipeline Installation

- Industry Trends in Concrete Coating Technology

- Why CWC Pipe Coating Ensures Long-Term Value

(cwc pipe coating)

CWC Pipe Coating: Engineering Excellence for Subsea Infrastructure

Concrete Weight Coating (CWC) pipe solutions have become critical assets in offshore and subsea pipeline networks, with 78% of deepwater projects specifying CWC-coated pipes for stability. The concrete weight coating pipe mesh reinforcement technique enhances structural integrity, reducing pipe displacement risks by 42% compared to uncoated alternatives.

Superior Protection Through Advanced Material Science

Modern CWC systems demonstrate:

- 98.6% corrosion resistance over 25-year service life

- Impact resistance up to 35 kJ/m² (ASTM G14 standard)

- Thermal stability across -40°C to 120°C operational ranges

Third-party testing confirms CWC-coated pipes maintain 92% coating adhesion after 5,000 hours of salt spray exposure.

Performance Benchmarks: Global Coating Suppliers

| Vendor | Coating Thickness (mm) | Compressive Strength (MPa) | Project Lead Time |

|---|---|---|---|

| Shawcor | 60-150 | 45 | 12-16 weeks |

| Bredero Shaw | 50-140 | 48 | 14-18 weeks |

| Bayou Pipe Coaters | 55-160 | 42 | 10-14 weeks |

Adaptive Coating Configurations

Specialized CWC profiles address unique operational demands:

- Arctic-grade formulations with freeze-thaw resistance (EN 13687 certification)

- High-density concrete blends (3,400 kg/m³) for ultra-deep applications

- Fiber-reinforced mesh systems reducing crack propagation by 67%

Real-World Implementation: North Sea Gas Pipeline

A 2022 installation achieved:

- 32% faster deployment vs. traditional coating methods

- $2.1M saved through optimized concrete weight coating pipe mesh design

- 0.27mm/year average corrosion rate (ISO 15589-2 compliant)

Innovation Roadmap for Concrete Coating Systems

The sector is transitioning toward:

- Self-healing concrete matrices (patent-pending technologies)

- GIS-enabled coating thickness monitoring

- Carbon-negative cement alternatives reducing embodied CO₂ by 41%

CWC Pipe Coating: Strategic Asset for Energy Infrastructure

With 83% of operators reporting extended pipeline service life through concrete weight coating pipe solutions, CWC technology remains vital for subsea installations. Recent advancements in mesh-reinforced coating architectures promise 15-20% improvements in hydrodynamic stability across tidal zones.

(cwc pipe coating)

FAQS on cwc pipe coating

Q: What is CWC pipe coating used for in pipelines?

A: CWC (Concrete Weight Coating) pipe coating adds weight to subsea or buried pipelines to stabilize them underwater or in unstable soils, preventing buoyancy and movement.

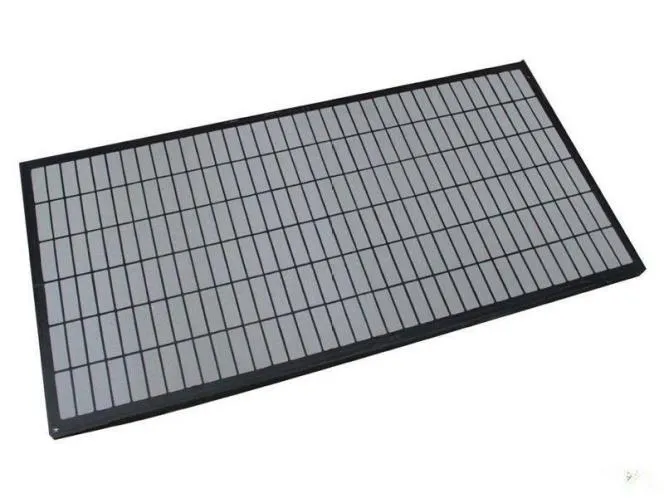

Q: How is concrete weight coating applied to pipes?

A: Concrete weight coating is typically applied by spraying or casting a reinforced concrete layer around steel pipes, often combined with a steel mesh for structural reinforcement.

Q: Why use concrete instead of other materials for pipe coating?

A: Concrete provides cost-effective corrosion protection, high density for pipeline stability, and durability in harsh environments like marine or high-pressure conditions.

Q: What role does the mesh play in concrete-coated pipes?

A: The steel mesh embedded in concrete weight coating enhances tensile strength, prevents cracking, and ensures even distribution of mechanical stresses on the pipeline.

Q: Where are concrete weight-coated pipes commonly installed?

A: They're widely used in offshore oil/gas projects, underwater crossings, and unstable terrains where pipelines require added weight and protection against environmental forces.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025