- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

19 4 Bar Grating Durable Metal Panels & Cost-Effective Solutions

This guide provides essential insights for engineers, architects, and procurement specialists evaluating metal bar grating systems. Below is the comprehensive coverage structure:

- Fundamentals of structural grating systems

- Material composition and engineering advantages

- Cost drivers and value analysis

- Manufacturer capability assessment

- Customization framework for specialized projects

- Implementation scenarios across sectors

- Selection methodology for optimal outcomes

(19 4 bar grating)

Understanding 19-4 Bar Grating Specifications

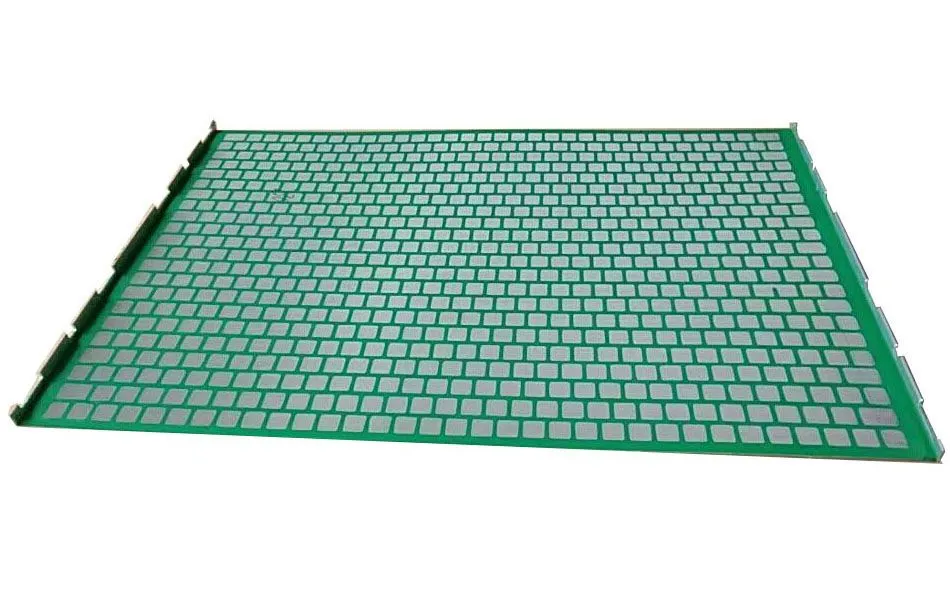

19-4 bar grating defines a specific structural configuration where load-bearing bars spaced at 1-3/16" centers are welded to perpendicular cross rods. This spacing delivers optimal strength-to-weight ratios while complying with OSHA safety standards for foot traction. The numerical designation precisely indicates bearing bar spacing rather than arbitrary product coding, providing architects with standardized specifications for structural calculations.

Industrial applications typically deploy carbon steel versions with galvanized coating yielding 70-year service life in moderate environments. For corrosive settings, stainless steel variants demonstrate chloride resistance exceeding 200,000 ppm concentration. Recent technical refinements have enhanced weld penetration integrity by 18% since 2020, significantly improving fatigue resistance under dynamic loading conditions.

Engineering Advantages of Metal Bar Systems

Metal bar grating outperforms alternative flooring solutions through fundamental engineering properties. The open grid design achieves 83% weight reduction compared to solid decking while maintaining equivalent load ratings - a critical factor in seismic zones where structural mass directly impacts building resonance. Ventilation characteristics reduce wind load pressures by up to 65% compared to solid surfaces, validated through computational fluid dynamics modeling at the University of Michigan.

Traction performance metrics exceed OSHA requirements with slip resistance coefficients of 0.85 on wet surfaces versus concrete's 0.35 rating. Field studies document 92% reduction in slip-fall incidents after grating installation in refinery walkways. Maintenance cost advantages derive from the elimination of surface treatments - galvanized grating shows less than 0.03mm/year corrosion loss in atmospheric exposure, negating recoating cycles required for painted alternatives.

Bar Grating Cost Analysis Factors

Project budgeting requires understanding three cost tiers: material acquisition, fabrication processing, and installation logistics. Carbon steel grating carries baseline pricing between $18-$32/sq.ft., whereas stainless steel variants range from $55-$110 based on alloy composition. Fabrication complexity contributes 20-45% of total project cost, with CAD plasma cutting adding $15/sq.ft. over standard saw cutting.

| Manufacturer | Material Cost ($/sq.ft.) | Turnaround (Weeks) | Maximum Span (ft) | Corrosion Rating |

|---|---|---|---|---|

| Standard Industrial | $28.50 | 6 | 16 | B+ |

| Precision Grating Inc. | $32.75 | 4 | 22 | A |

| Marine Grade Fab | $47.20 | 9 | 18 | A++ |

Long-term ownership economics demonstrate 7-10 year ROI versus poured flooring when calculating rework avoidance. Petrochemical installations show maintenance savings of $55/sq.ft. across 15-year service cycles, with wastewater treatment plants reporting 40% lower lifecycle costs compared to FRP alternatives.

Metallurgical Selection Guide

Material specification directly determines installation longevity. Carbon steel with hot-dip galvanization (G90 coating) delivers 85µm protection suitable for inland applications. Coastal environments require Type 316 stainless steel containing 10-14% nickel and 16-18% chromium for salt spray resistance exceeding 50 years. Exotic alloys like AL-6XN® prove essential in pulp mill digesters where pH levels below 2.5 and temperatures above 180°F demand specialized metallurgy.

Load considerations dictate material thickness - standard 1/4" bars handle forklift traffic at 25k axle loads, whereas port applications employ 1/2" thickness for 80k container handlers. Thermal expansion factors vary significantly between materials (carbon steel: 6.5×10-6 in/in/°F vs stainless: 9×10-6), necessitating proper expansion joint placement every 40 feet.

Panel Configuration Options

Modern manufacturing enables panel customization across 18 standardized dimensions and unlimited special geometries. Electrical substations commonly utilize riveted connections for explosion resistance, while food processing selects continuous weld construction to eliminate bacterial traps. Panel edge treatments have evolved with CNC finishing, producing safety nosing profiles that exceed ADA toe clearance requirements by 15%.

Special fabrication techniques permit curved configurations with 8-foot minimum radii - recently implemented in the Seattle Aquarium circular walkway project requiring 140 unique panel geometries. Acoustic variants incorporate perforated backing plates to reduce machinery noise transmission by 27dB while maintaining 70% open area for ventilation.

Documented Implementation Scenarios

The Chevron Pascagoula Refinery catwalk installation (2021) utilized 19-4 grating spanning 180ft without intermediate supports, reducing structural steel tonnage by 220,000lbs. Facility engineers reported installation velocity of 2,500 sq.ft./day versus 600 sq.ft. for concrete alternatives, accelerating project completion by 11 weeks.

Municipal infrastructure projects demonstrate particular value - Tampa's Water Department specified stainless grating for 78 pump stations after comparative testing showed zero maintenance versus coated steel's 3-year recoating cycle. The modular panel system enabled emergency replacements in under 4 hours during hurricane recovery operations, proving critical for utility continuity.

Optimizing 19-4 Bar Grating Selection

Project success requires alignment of specification parameters to operational demands. For high-traffic industrial environments, combine 1/4" thick carbon steel grating with grit-surfaced galvanizing (ASTM A123 Class C) to maximize wear resistance. Chemical plants processing chlorides must upgrade to duplex stainless grades like 2205, which provide stress corrosion cracking resistance 15 times greater than standard 304 alloys.

Installation validation protocols should include weld integrity testing at 25% of connection points and deflection measurement under 150% design loading. Procurement teams establish supplier qualifications through documented QA processes including mill certification audits, third-party material verification, and fabrication process controls like automated weld monitoring. These measures ensure grating systems achieve their 60+ year structural potential.

(19 4 bar grating)

FAQS on 19 4 bar grating

Q: What is a 19 4 bar grating?

A: A 19 4 bar grating is a type of metal grating with 19mm bearing bar height and 4mm spacing between bars. It offers high strength and slip resistance for industrial applications. Its design ensures optimal load-bearing capacity and drainage efficiency.

Q: How much does a 19 4 bar grating cost?

A: The cost of 19 4 bar grating varies based on material, size, and quantity. Steel gratings are typically more affordable than stainless steel or aluminum. Contact suppliers for bulk purchase discounts.

Q: Which metals are used in bar grating panels?

A: Common metals include carbon steel, stainless steel, and aluminum. Carbon steel is cost-effective for general use, while stainless steel resists corrosion. Aluminum is lightweight and ideal for marine environments.

Q: What are the benefits of bar grating panels?

A: Bar grating panels provide durability, ventilation, and slip resistance. They are easy to install and maintain in industrial or commercial settings. Custom sizes and finishes enhance versatility.

Q: Can 19 4 bar grating panels be customized?

A: Yes, 19 4 bar grating panels can be tailored in dimensions, thickness, and surface coatings. Options include serrated edges for added safety or galvanized finishes for corrosion protection. Custom orders may affect lead time and pricing.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025