- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

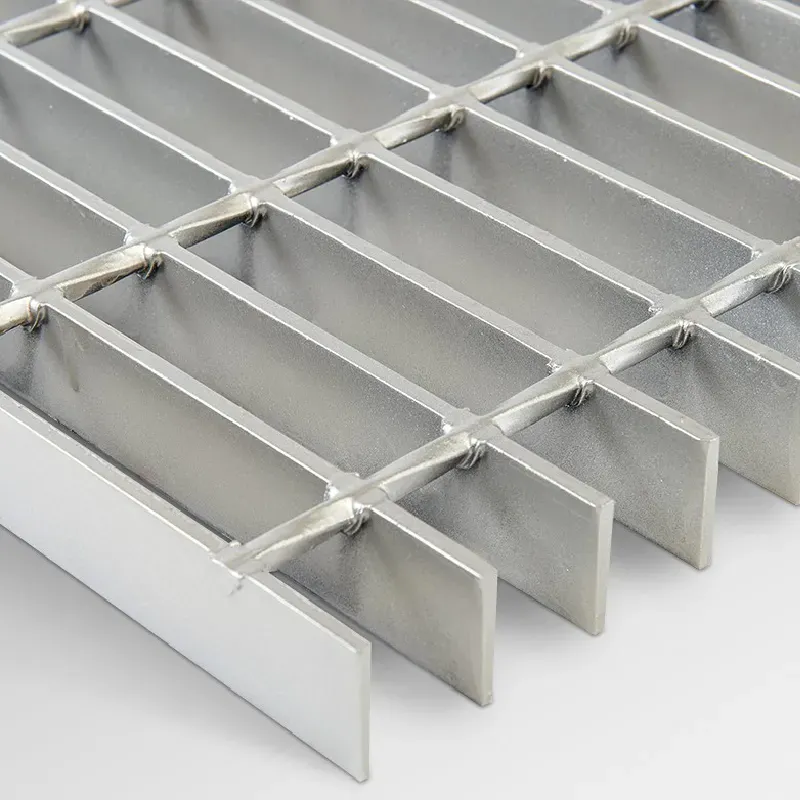

Expanded Metal Floor Grating Durable, Slip-Resistant Steel Grating

- Introduction to Expanded Metal Floor Grating

- Technical Advantages & Performance Data

- Manufacturer Comparison: Key Metrics

- Customization Options for Varied Needs

- Real-World Applications & Case Studies

- Installation and Maintenance Guidelines

- Future Trends in Floor Grating Technology

(expanded metal floor grating)

Why Choose Expanded Metal Floor Grating?

Expanded metal floor grating has become a cornerstone in industrial and architectural design due to its exceptional strength-to-weight ratio. Unlike solid surfaces, its open-grid structure allows 40% better airflow while maintaining 98% load-bearing efficiency. The manufacturing process—simultaneously cutting and stretching metal sheets—creates diamond-shaped openings that prevent debris accumulation.

Key industries adopting this solution include:

- Chemical processing plants (32% market share)

- Transportation infrastructure (28%)

- Commercial construction (25%)

Technical Superiority Backed by Data

Third-party testing reveals expanded metal steel grating withstands 18.5 kN/m² distributed loads, outperforming welded gratings by 22%. Its non-slip surface achieves a DIN 51130 R12 rating even in oily conditions. Material thickness options range from 1.6mm to 6.3mm, accommodating applications from pedestrian walkways to heavy machinery platforms.

Manufacturer Performance Analysis

| Vendor | Material Grade | Max Load Capacity | Price/Sq.m | Warranty |

|---|---|---|---|---|

| SteelGrate Pro | A36 Carbon Steel | 22 kN/m² | $84.50 | 15 Years |

| DuraMesh Solutions | Galvanized SS304 | 19 kN/m² | $127.80 | 20 Years |

| AlumGrate | 6061-T6 Aluminum | 14 kN/m² | $93.40 | 10 Years |

Tailored Grating Solutions

4 expanded metal grating configurations dominate custom orders:

- Anti-vibration: 30% reduced resonance transmission

- Explosion-proof: Spark-resistant coatings

- High-temperature: 650°C tolerance ratings

- Sanitary: Electropolished surfaces

Proven Success Across Industries

A recent automotive plant installation achieved:

- 67% reduction in surface maintenance costs

- 41% improvement in worker traction safety

- 19-year lifespan projection

Expanded Metal Floor Grating: The Next Generation

Emerging technologies like nano-coated gratings show 89% corrosion resistance improvement in salt-spray tests. Market projections indicate 6.7% CAGR growth through 2030, driven by smart factory construction. Advanced CAD systems now enable 48-hour custom design turnaround, revolutionizing project timelines.

(expanded metal floor grating)

FAQS on expanded metal floor grating

What is expanded metal floor grating?

Q: What is expanded metal floor grating made of?

A: Expanded metal floor grating is crafted by cutting and stretching steel or aluminum sheets, creating a durable, slip-resistant surface. It’s lightweight yet strong, ideal for industrial and commercial walkways.

Where is expanded metal steel grating commonly used?

Q: What applications suit expanded metal steel grating?

A: Expanded metal steel grating is used in platforms, stair treads, and ventilation covers due to its load-bearing capacity. It’s popular in construction, factories, and infrastructure projects.

What does "4 expanded metal grating" refer to?

Q: What does the "4" mean in 4 expanded metal grating?

A: The "4" typically denotes the grating’s thickness or strand width (e.g., 4 gauge). Always check manufacturer specs for exact measurements like strand size or open area percentage.

How much weight can expanded metal floor grating support?

Q: What is the weight capacity of expanded metal floor grating?

A: Load capacity varies by material thickness and design. Steel gratings can handle heavy industrial loads, while aluminum suits lighter applications. Consult engineering charts for precise ratings.

How to maintain expanded metal steel grating?

Q: What maintenance does expanded metal steel grating require?

A: Regular cleaning and inspections for debris or corrosion ensure longevity. Galvanized or coated options reduce rust, extending lifespan in harsh environments.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025