- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Peb . 05, 2025 04:20

Back to list

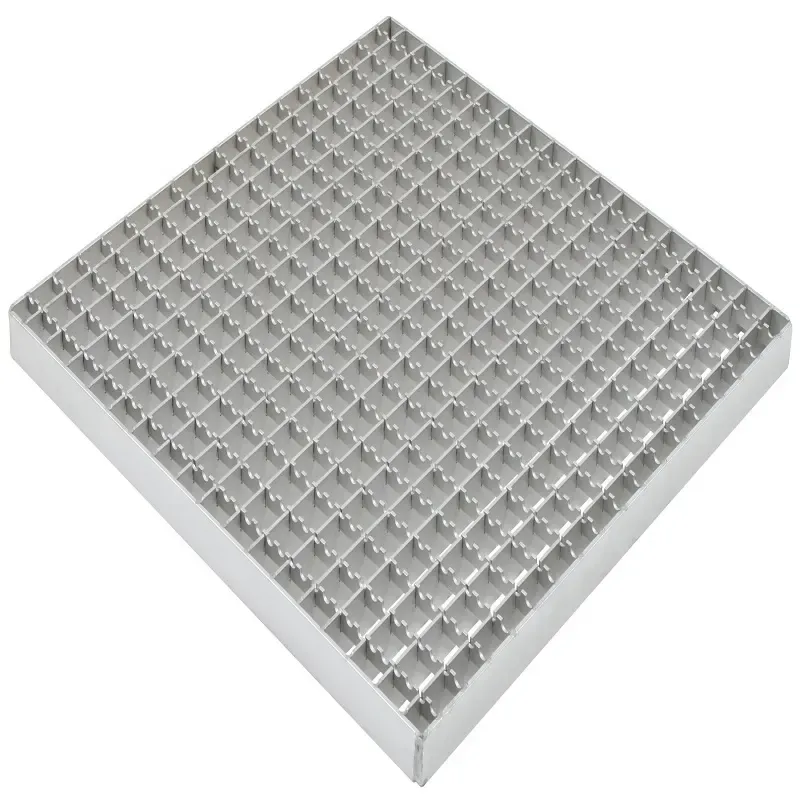

steel walkway grating

The cost of steel grating can significantly impact budgeting decisions across diverse industries. As a long-lasting, versatile, and robust option for flooring, walkways, and platforms, understanding the factors influencing its price is essential for procurement and project planning. Steel grating is known for its durability and load-bearing capabilities, making it a popular choice in industrial and commercial applications. However, its pricing can vary widely depending on several key factors.

Market fluctuations in the global steel industry can further affect steel grating prices. Steel prices are subject to change based on supply and demand dynamics, raw material availability, and geopolitical factors. In periods of high demand or limited supply, steel prices can escalate, thereby increasing manufacturing costs for steel grating producers and, consequently, the prices for end-users. Installation and shipping considerations are additional factors worth noting. Projects located in remote areas may incur higher shipping costs due to the weight of the steel grating, affecting the total expenditure. Packaging and protection during transit can also add to costs, especially for international shipments. Installation costs vary based on site conditions, labor rates, and complexity of installation, thus playing a pivotal role in the total project cost. To optimize costs effectively, businesses are advised to work with reputable suppliers who can offer competitive pricing without compromising quality. By sourcing directly from manufacturers or authorized distributors, buyers can often negotiate better terms and gain access to bulk purchase discounts. Requesting samples and thoroughly reviewing specifications can help ensure alignment with project needs and prevent costly adjustments later. For project planners and procurement managers, a comprehensive understanding of these factors ensures accurate budget forecasting and cost management. Investing in steel grating is a decision that requires careful consideration of immediate costs versus long-term benefits such as durability, maintenance, and safety. By taking into account material type, manufacturing methods, market conditions, and installation factors, stakeholders can make informed decisions that align with both project requirements and financial constraints.

Market fluctuations in the global steel industry can further affect steel grating prices. Steel prices are subject to change based on supply and demand dynamics, raw material availability, and geopolitical factors. In periods of high demand or limited supply, steel prices can escalate, thereby increasing manufacturing costs for steel grating producers and, consequently, the prices for end-users. Installation and shipping considerations are additional factors worth noting. Projects located in remote areas may incur higher shipping costs due to the weight of the steel grating, affecting the total expenditure. Packaging and protection during transit can also add to costs, especially for international shipments. Installation costs vary based on site conditions, labor rates, and complexity of installation, thus playing a pivotal role in the total project cost. To optimize costs effectively, businesses are advised to work with reputable suppliers who can offer competitive pricing without compromising quality. By sourcing directly from manufacturers or authorized distributors, buyers can often negotiate better terms and gain access to bulk purchase discounts. Requesting samples and thoroughly reviewing specifications can help ensure alignment with project needs and prevent costly adjustments later. For project planners and procurement managers, a comprehensive understanding of these factors ensures accurate budget forecasting and cost management. Investing in steel grating is a decision that requires careful consideration of immediate costs versus long-term benefits such as durability, maintenance, and safety. By taking into account material type, manufacturing methods, market conditions, and installation factors, stakeholders can make informed decisions that align with both project requirements and financial constraints.

Share

Prev:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025