- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Peb . 14, 2025 17:29

Back to list

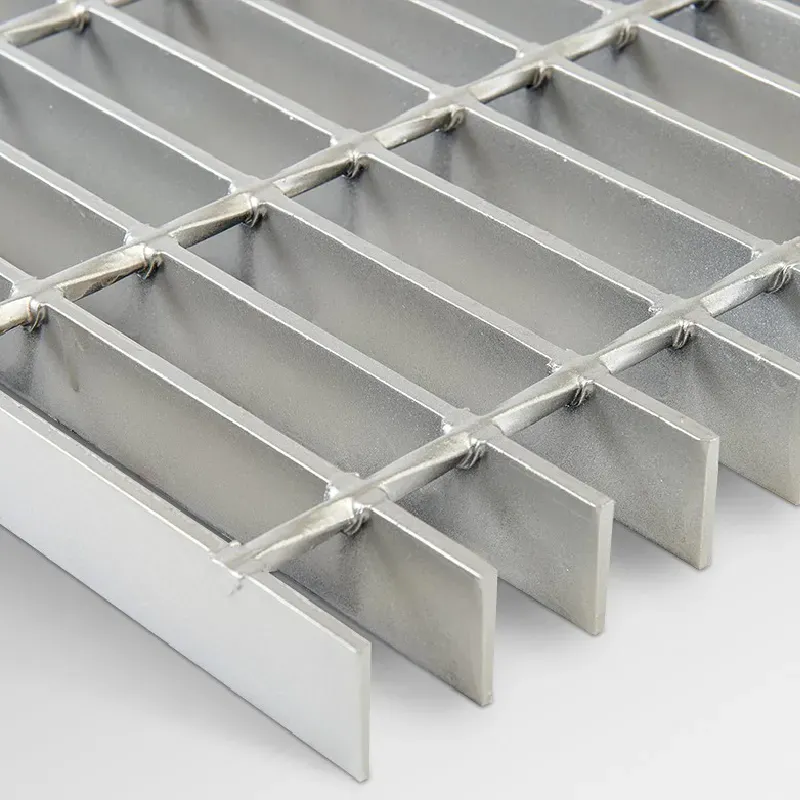

heavy-duty welded bar grating

Understanding the weight of bar grating per square foot is crucial in ensuring the proper selection and application in various industries. Bar grating, a versatile material used for creating flooring, platforms, and stairs, requires precision in its application due to the structural impacts that weight can have. The calculated weight of the grating directly influences the overall design, cost, and functionality of industrial and architectural projects.

Expertise in this field extends beyond merely selecting materials and calculating weights. It requires an intimate understanding of the environmental conditions the grating will face. Engineers must consider factors such as weather exposure, chemical exposure, and the potential for wear and tear over time. Understanding these elements ensures that the chosen bar grating will not only bear the required load but will endure the test of time, which speaks directly to the grating's lifespan and long-term value. Authoritativeness in the bar grating market is often dictated by manufacturers and suppliers with a proven track record of quality and reliability. Trusting in a reputable provider ensures the materials meet stringent industry standards for weight measurement and structural integrity. These companies offer detailed specifications and guidelines that aid in the selection process, ensuring all technical requirements are met. Trustworthiness is perhaps the most crucial factor consumers consider when selecting bar grating. Every application demands a high level of confidence in the product’s performance. As such, establishing trust involves not only meeting but often exceeding industry standards and customer expectations. Demonstrating successful past installations and offering warranties or guarantees can greatly enhance credibility and customer trust. In summary, the weight of bar grating per square foot is an essential consideration that affects the overall effectiveness, safety, and longevity of an application. By leveraging experience and expertise, one can ensure that the selection of bar grating is both appropriate and reliable, adhering to the core principles of authoritativeness and trustworthiness. Whether for industrial or architectural applications, selecting the right type of bar grating with the correct weight ensures a harmonious balance between functionality and safety, protecting both the investment and the people who rely on these critical structural elements.

Expertise in this field extends beyond merely selecting materials and calculating weights. It requires an intimate understanding of the environmental conditions the grating will face. Engineers must consider factors such as weather exposure, chemical exposure, and the potential for wear and tear over time. Understanding these elements ensures that the chosen bar grating will not only bear the required load but will endure the test of time, which speaks directly to the grating's lifespan and long-term value. Authoritativeness in the bar grating market is often dictated by manufacturers and suppliers with a proven track record of quality and reliability. Trusting in a reputable provider ensures the materials meet stringent industry standards for weight measurement and structural integrity. These companies offer detailed specifications and guidelines that aid in the selection process, ensuring all technical requirements are met. Trustworthiness is perhaps the most crucial factor consumers consider when selecting bar grating. Every application demands a high level of confidence in the product’s performance. As such, establishing trust involves not only meeting but often exceeding industry standards and customer expectations. Demonstrating successful past installations and offering warranties or guarantees can greatly enhance credibility and customer trust. In summary, the weight of bar grating per square foot is an essential consideration that affects the overall effectiveness, safety, and longevity of an application. By leveraging experience and expertise, one can ensure that the selection of bar grating is both appropriate and reliable, adhering to the core principles of authoritativeness and trustworthiness. Whether for industrial or architectural applications, selecting the right type of bar grating with the correct weight ensures a harmonious balance between functionality and safety, protecting both the investment and the people who rely on these critical structural elements.

Share

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025