- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

jan . 20, 2025 03:18

Back to list

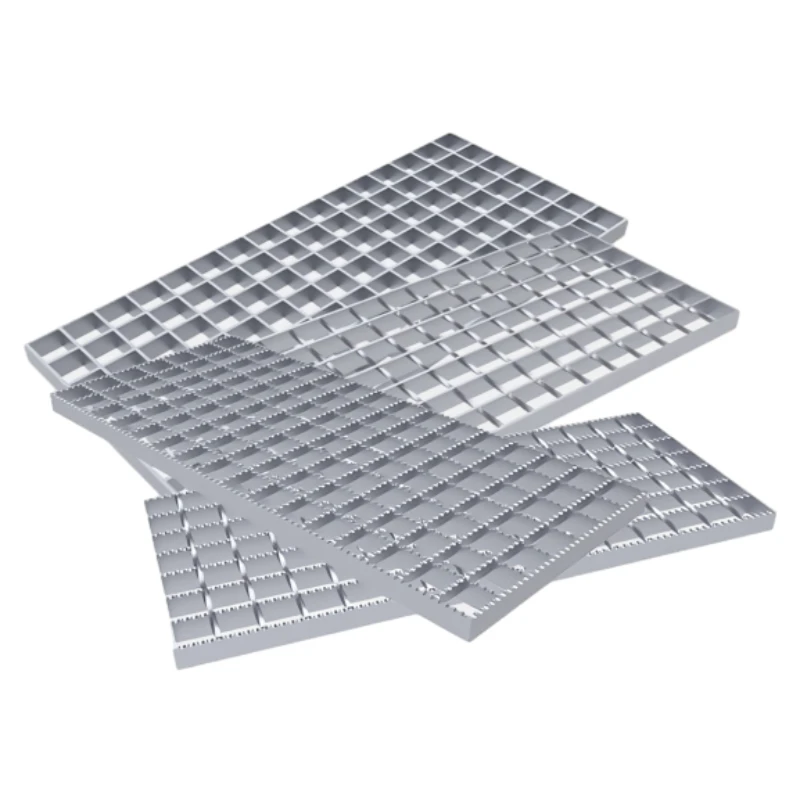

Steel Grating

Stainless steel grating is an indispensable product renowned for its remarkable durability, corrosion resistance, and unmatched versatility. Commonly used in industries such as food processing, chemical manufacturing, and wastewater treatment, stainless grating stands as a benchmark for safety and hygiene standards.

The trustworthiness of stainless grating is reflected in its wide acceptance across critical applications. In petrochemical plants, where flammable materials are present, the safety of non-sparking and non-conductive grating cannot be overstated. This reassurance of safety fosters an environment where workers can operate confidently, knowing that the infrastructure supports accident prevention. From a sustainability perspective, stainless steel grating checks all the right boxes. Its durability translates into less frequent replacements, reducing material waste. Furthermore, stainless steel is fully recyclable, supporting industrial contributions to circular economy principles. This eco-friendly aspect enhances the product's appeal in a world increasingly focused on sustainability. Innovations in the manufacturing of stainless grating continue to drive industry standards forward. Advanced techniques like electropolishing not only improve the surface finish but also enhance the alloy's inherent anti-corrosive properties. As technology advances, newer variants of stainless steel grating promise even higher performance levels, ensuring this product remains at the forefront of material solutions in industrial applications. In conclusion, stainless steel grating is more than just a component— it's a comprehensive solution embodying safety, hygiene, and robustness in varied industrial landscapes. Its proven track record, backed by stringent manufacturing standards and expert endorsements, provides an authoritative voice in quality assurance. When incorporated into any environment, from industrial floors to architectural marvels, stainless steel grating stands out as a testament to enduring quality and performance, trusted by experts worldwide.

The trustworthiness of stainless grating is reflected in its wide acceptance across critical applications. In petrochemical plants, where flammable materials are present, the safety of non-sparking and non-conductive grating cannot be overstated. This reassurance of safety fosters an environment where workers can operate confidently, knowing that the infrastructure supports accident prevention. From a sustainability perspective, stainless steel grating checks all the right boxes. Its durability translates into less frequent replacements, reducing material waste. Furthermore, stainless steel is fully recyclable, supporting industrial contributions to circular economy principles. This eco-friendly aspect enhances the product's appeal in a world increasingly focused on sustainability. Innovations in the manufacturing of stainless grating continue to drive industry standards forward. Advanced techniques like electropolishing not only improve the surface finish but also enhance the alloy's inherent anti-corrosive properties. As technology advances, newer variants of stainless steel grating promise even higher performance levels, ensuring this product remains at the forefront of material solutions in industrial applications. In conclusion, stainless steel grating is more than just a component— it's a comprehensive solution embodying safety, hygiene, and robustness in varied industrial landscapes. Its proven track record, backed by stringent manufacturing standards and expert endorsements, provides an authoritative voice in quality assurance. When incorporated into any environment, from industrial floors to architectural marvels, stainless steel grating stands out as a testament to enduring quality and performance, trusted by experts worldwide.

Share

Prev:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025