- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

shale shaker screen material

Understanding Shale Shaker Screen Materials

Shale shakers are essential components in the drilling industry, playing a crucial role in separating the cuttings and solids from the drilling fluid or mud. The effectiveness and reliability of shale shakers significantly depend on the quality of the shaker screens employed. One critical aspect that determines the performance of these screens is the material from which they are made. In this article, we will explore various materials used in shale shaker screens, highlighting their properties, advantages, and considerations for selection.

Common Materials Used for Shale Shaker Screens

1. Steel Wire Mesh One of the most common materials used for shaker screens is steel wire mesh. Steel screens are renowned for their durability and strength, making them suitable for high-pressure and high-temperature applications. They can withstand harsh conditions often encountered in drilling operations. The wire mesh is available in various mesh sizes, allowing operators to customize the screen for specific drilling conditions and types of cuttings.

2. Polyurethane Polyurethane screens are increasingly popular due to their lightweight nature and resistance to corrosion and abrasion. Unlike steel, polyurethane is less likely to rust or degrade over time, providing a longer lifespan in various operating environments. Additionally, the flexibility of polyurethane allows for various designs and shapes of screens, accommodating different shaker configurations.

3. Composite Materials Composite screens represent the latest technology in the fabrication of shale shaker screens. These screens combine the durability of steel with the lightweight and corrosion-resistant properties of polymer materials. The result is a screen that maintains the structural integrity of metal screens while being more resistant to wear and tear. Composite materials provide an excellent balance between performance and longevity, making them a favored choice among operators.

4. Synthetic Fabrics Synthetic fabric screens, often made from high-tensile fibers, are another innovation in shaker screen technology. These fabrics offer high tensile strength while remaining lightweight. They are particularly effective at capturing finer solids, making them suitable for applications where precision and efficiency are critical. Their resistance to chemical treatments also makes them ideal for various fluid types.

Key Properties of Shale Shaker Screen Materials

shale shaker screen material

When choosing materials for shale shaker screens, several key properties should be considered

- Durability The chosen material must withstand the abrasive nature of drilling cuttings and the stresses from high-pressure environments. - Weight Lighter materials can improve the overall efficiency of the shaker system and reduce operational fatigue on the equipment. - Corrosion Resistance Given the various chemicals present in drilling muds, materials that resist corrosion can greatly enhance the lifespan of the screens. - Mesh Size Flexibility The ability to customize mesh sizes based on the specific drilling needs ensures optimal performance during operations. - Cost-Effectiveness While longevity and durability are crucial, the overall cost of materials should align with operational budgets.

Selecting the Right Material

Choosing the appropriate material for shale shaker screens involves understanding the specific conditions of the drilling operation. For instance, in environments with highly abrasive materials, steel may provide the necessary strength. Conversely, in chemically aggressive environments, synthetic or composite materials may be better suited to prolong the screen's lifespan and efficiency.

Operators must work closely with manufacturers and suppliers to identify the best options tailored to their drilling needs. Moreover, regular maintenance and monitoring of shaker screens are essential to ensure performance remains optimal throughout the drilling process.

Conclusion

In conclusion, the material of shale shaker screens plays a pivotal role in the efficiency, durability, and effectiveness of the drilling process. By understanding the properties and advantages of various materials, drilling operators can make informed choices that enhance their operational success. As technology continues to evolve, innovative materials will likely emerge, further enhancing the capabilities of shale shaker screens and improving drilling operations globally. Ensuring that your equipment is equipped with the right screens not only promotes safety and efficiency but also contributes to the overall productivity of drilling projects.

-

Unlocking Efficiency with Premium Shaker ScreensNewsAug.05,2025

-

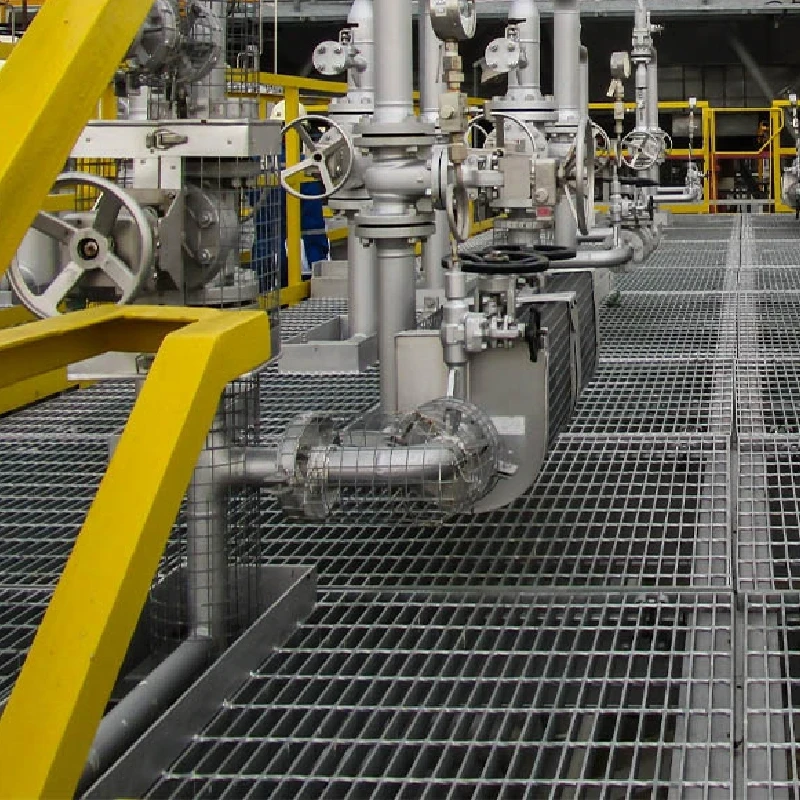

Safety and Style with Metal Grate WalkwayNewsAug.05,2025

-

Optimize Operations with Shaker Screen SolutionsNewsAug.05,2025

-

Enhance Your Space with Steel GratingNewsAug.05,2025

-

Durability with Concrete Weight Coating MeshNewsAug.05,2025

-

Discover the Power of Perimeter Safety NetNewsAug.05,2025