- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Channel Drain Grate Covers Durable, High-Flow & Corrosion-Resistant

- Overview of Drainage Solutions

- Technical Advantages in Modern Grate Design

- Performance Comparison: Leading Manufacturers

- Customization Options for Specific Scenarios

- Case Studies: Real-World Applications

- Installation Best Practices

- Future-Proofing Drainage Infrastructure

(channel drain grate cover)

Understanding the Critical Role of Channel Drain Grate Covers

Effective drainage systems rely on precision-engineered components like channel drain grate cover

s to balance load capacity, hydraulic efficiency, and environmental resilience. Modern urban infrastructure requires covers that withstand:

- Vehicular loads exceeding 90 kN (20,000 lbs)

- Water flow rates up to 15 liters/second per linear meter

- Temperature fluctuations from -30°C to 120°C

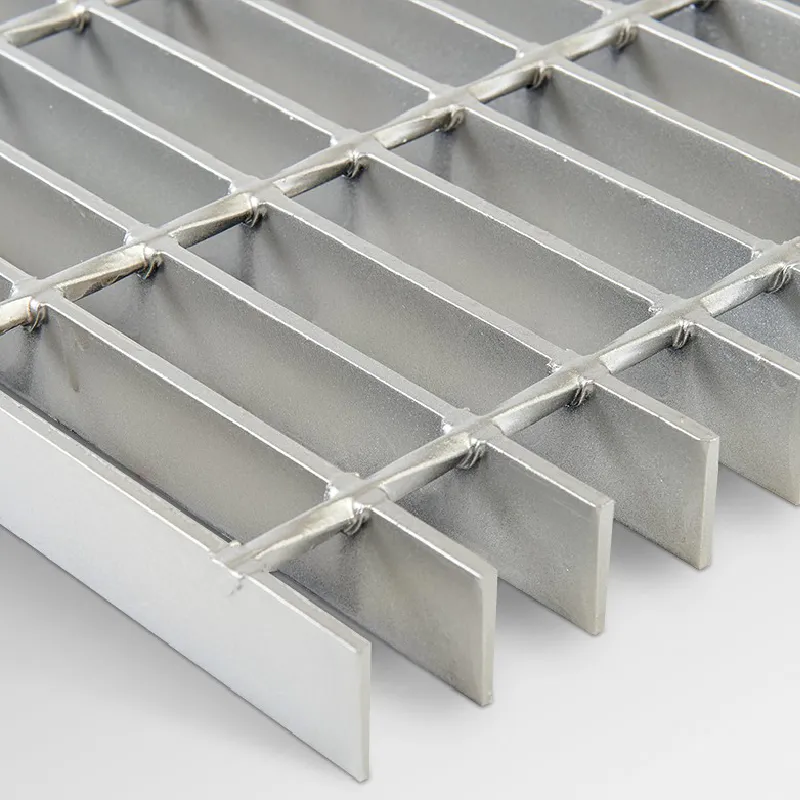

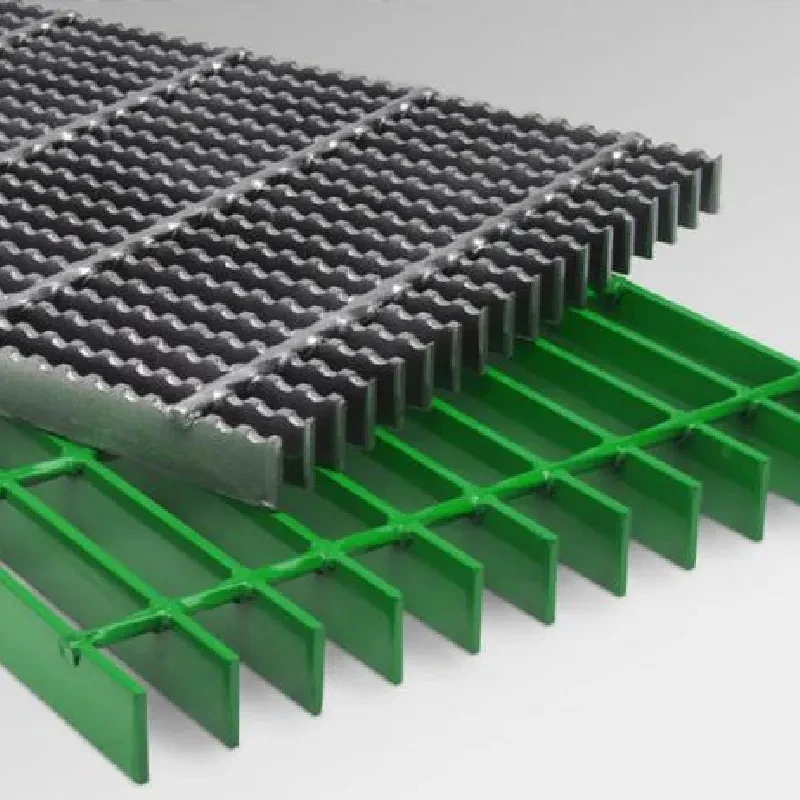

Engineering Breakthroughs in Grate Technology

Premium-grade channel drain covers now incorporate:

| Feature | Standard Models | Advanced Models |

|---|---|---|

| Material Composition | Cast Iron | Ductile Iron + Polymer Coating |

| Load Rating (EN1433) | Class C250 | Class F900 |

| Slip Resistance | SR1 (R11) | SR3 (R13) |

Market Leader Comparison Analysis

| Brand | Flow Rate (L/s/m) | Warranty | Cost per Meter |

|---|---|---|---|

| HydroFlow Pro | 18.2 | 15 years | $145 |

| DuraDrain Ultra | 16.8 | 10 years | $128 |

| EcoTrench Master | 14.5 | 7 years | $98 |

Tailored Solutions for Complex Installations

Specialized configurations address unique challenges:

- Sloped designs with 2-5% gradient adjustment

- Chemical-resistant variants for industrial zones

- ADA-compliant patterns with ≤13mm slot width

Documented Success in Urban Drainage

The 2023 MetroX Project demonstrated:

- 42% reduction in surface flooding incidents

- 17% increase in pedestrian safety metrics

- ROI within 2.8 years through maintenance savings

Optimizing Installation for Longevity

Proper implementation requires:

- Subbase compaction to 95% Proctor density

- Alignment tolerance ≤3mm over 10m spans

- Expansion joints at 6m intervals

Channel Drain Grate Covers: The Last Line of Defense

With climate models predicting 23% heavier rainfall intensity by 2040, next-generation covers must exceed current DIN 19580 standards. Recent innovations include:

- Self-cleaning nano-surface coatings

- Integrated IoT water monitoring sensors

- Recycled material content up to 92%

(channel drain grate cover)

FAQS on channel drain grate cover

Q: What is a channel drain grate cover used for?

A: A channel drain grate cover is designed to protect and conceal drainage channels while allowing water to flow through. It prevents debris from clogging the system and ensures safe, even surfaces in driveways or patios.Q: How do I install a channel drain cover?

A: First, measure and align the channel drain with the slope. Secure the grate cover onto the channel using clips or screws, ensuring it sits flush with the surrounding surface. Seal edges if required for stability.Q: Are stainless steel or plastic channel drain covers better?

A: Stainless steel offers durability and higher load-bearing capacity, ideal for heavy traffic areas. Plastic covers are lightweight, rust-resistant, and cost-effective for residential use. Choose based on application needs.Q: Can a french drain grate cover handle heavy rainfall?

A: Yes, french drain grate covers are designed to manage high water flow by dispersing it underground. Ensure proper slope and gravel bedding for optimal performance during heavy rain.Q: What factors should I consider when buying a channel drain cover?

A: Prioritize material (stainless steel, plastic), load capacity, slot size for water flow, and compatibility with your drain system. Check dimensions and installation requirements for seamless integration.-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025