- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

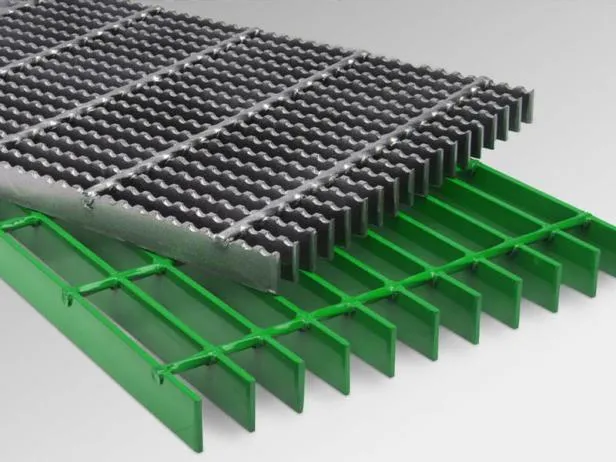

grating galvanized

The Significance of Grating in Galvanized Steel Applications

Grating galvanized steel is a versatile and durable material commonly used across various industries for its strength, corrosion resistance, and aesthetic appeal. Understanding the importance of this material requires a look at its construction, applications, and benefits, as well as how it plays a vital role in modern infrastructure.

What is Grating Galvanized Steel?

Grating refers to a framework of steel bars or plates that create an open surface, typically used for flooring, walkways, and platforms. Galvanization is a process that involves coating steel with a layer of zinc to protect it from corrosion. When combined, grating galvanized steel provides a sturdy solution that can withstand heavy loads and harsh environmental conditions. The galvanization process not only enhances the steel’s longevity but also makes it suitable for outdoor usage where exposure to moisture, chemicals, and varying temperatures is common.

Applications in Various Industries

Grating galvanized steel finds extensive use in diverse sectors, including construction, manufacturing, and transportation

.1. Construction In the construction industry, galvanized steel grating is widely used for flooring systems, stair treads, and industrial platforms. It allows for easy drainage of water and other liquids, thereby reducing the risk of slipping and maintaining safety standards.

2. Manufacturing Manufacturing facilities often adopt galvanized grating for walkways and access platforms around machinery. Its ability to support substantial weight makes it ideal for heavy equipment settings. Additionally, the open design of the grating allows for easy cleaning and maintenance of the workplace.

3. Transportation In transportation infrastructure, galvanized steel grating is utilized in bridges, railways, and access roads. It allows for efficient drainage runoff and minimizes the accumulation of debris. Furthermore, its robust nature ensures safety for vehicles and pedestrians alike.

grating galvanized

Benefits of Using Grating Galvanized Steel

The benefits of choosing grating galvanized steel as a construction material are manifold

- Corrosion Resistance One of the primary advantages is its resistance to rust and other corrosive elements. Galvanization protects the steel, prolonging its lifespan and reducing maintenance costs over time.

- Lightweight yet Strong Galvanized steel grating provides a strong yet lightweight solution. This characteristic enables easier installation and reduces the need for excessive structural support.

- Versatility The design flexibility of grating means it can be customized to fit various applications and aesthetic preferences. It can be produced in different sizes, patterns, and load capacities to suit specific needs.

- Safety The open design of grating allows for good visibility and airflow while providing excellent traction. This reduces the chances of slips and falls, making it a safer option for industrial and commercial use.

- Economic Efficiency Although the initial cost may be higher compared to other materials, the long-term savings due to reduced maintenance and replacement needs make galvanized grating a cost-effective choice.

In conclusion, grating galvanized steel stands out as a critical component in numerous applications due to its strength, durability, and suitability for harsh environments. As industries continue to prioritize safety and resource efficiency, the demand for galvanized grating is expected to grow, further establishing it as an essential material in modern engineering and construction. Emphasizing its properties and applications will ensure that stakeholders make informed decisions, ultimately enhancing the safety and functionality of their projects.

-

Upgrade Your Industrial Operations with Durable Steel GratingNewsJul.21,2025

-

Transform Your Flooring Solutions with Quality Floor GratingNewsJul.21,2025

-

Top-Quality Shale Shaker Screens for Your Drilling NeedsNewsJul.21,2025

-

High-Quality Steel Grating for All Your Industrial NeedsNewsJul.21,2025

-

Explore the Durability and Versatility of Galvanized Steel GratingNewsJul.21,2025

-

Ensure Maximum Safety with Premium Safety NetsNewsJul.21,2025